David L. "Dave" Jones is an Australian electronic design engineer and video blogger. He is the founder and host of EEVBlog. He is also the founder and co-host of The Amp Hour Podcast.

Show More

Suggest an edit

Creator Details

Location

Sydney NSW, Australia

Episode Count

396

Podcast Count

1

Total Airtime

2w, 4d

PCID

Suggest an edit

Manage This Profile

Are you David? Verify and edit this page to your liking.

David L Jones' Creator Profile

This is a podcast creator profile for David L Jones. This page showcases all of David L Jones' podcast credits and appearances such as hosted episodes, guest interviews, and behind-the-scenes work. You can follow this profile to get notifications of David L Jones' new podcast credits.

Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

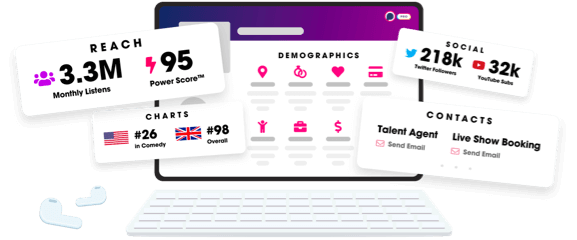

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us