Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:01

Skip Schwartz joins me this week to talk about

0:03

barrel-aged stouts. This is Beersmith

0:05

Podcast number 287.

0:17

This is the Beersmith Home Brewing

0:19

Show, where brewing great beer

0:21

is our passion. If you want to take your

0:23

brewing to the next level, visit beersmith.com,

0:27

where you can download a trial version of our Beersmith

0:29

software, subscribe to the newsletter,

0:31

and get dozens of free articles on home

0:34

brewing. And now, your host and

0:36

the author of Home Brewing with Beersmith, Brad

0:38

Smith.

0:39

This is Beersmith Podcast number 287, and it's

0:42

late August 2023. Skip

0:45

Schwartz joins me this week to talk about barrel-aged

0:47

stouts. Thank you to this week's sponsors,

0:50

Craft Beer and Brewing Magazine.

0:52

Every issue of Craft Beer and Brewing Magazine

0:54

is packed with articles for home brewers and beer lovers.

0:57

They offer access to videos, brewing courses,

1:00

exclusive articles,

1:02

and the amazing Craft Beer and Brewing Magazine.

1:04

Go to beerandbrewing.com to get

1:07

your subscription today.

1:09

And also the American Home Brewers Association.

1:12

The Home Brewers Association invites

1:14

you to choose your own brew venture.

1:16

Join for one year and select a free brewing

1:18

book for more than 60 titles.

1:21

Visit homebrewersassociation.org

1:23

slash beersmith to join the American

1:25

Home Brewers Association and treat

1:27

yourself to a new brewing book. Again,

1:30

that special link is homebrewersassociation.org

1:34

slash beersmith. And

1:36

the Beersmith Web, the online version of

1:38

Beersmith Brewing Software.

1:40

Beersmith for the Web lets you create

1:43

great beer recipes from

1:45

any browser, including your tablet or phone.

1:48

Edit recipes on the go with access to the same

1:50

full suite of recipe building tools as

1:52

our desktop version.

1:54

Try Beersmith Web today by creating a

1:56

free account at beersmithrecipes.com.

2:00

And finally, a reminder to click that like and

2:02

subscribe button on YouTube, iTunes,

2:05

Spotify, or whatever platform you're listening

2:07

on.

2:08

Clicking those buttons is a great way to support

2:10

the show. And now let's jump

2:12

into this week's episode.

2:16

Today on the show, I welcome Skip Schwartz from

2:18

Weldworks Brewing. Skip is the head brewer

2:20

at Weldworks. And today he joins us to talk

2:22

about the Barrel Age Beer Program.

2:25

Skip, it's great to have you on the show. How are you doing today?

2:27

I'm doing very well. Thank you. Thank you

2:30

for having me. I'm excited to talk to you about some barrel

2:33

age stouts. Yeah. I've had Neil.

2:36

Neil and I are friends way back. And of

2:38

course, Neil's been involved in Weldworks I think

2:40

is one of the founders. But

2:42

I wanted to find out a little bit about you. How did you get involved

2:45

in brewing and how did you end up as

2:47

the head brewer at Weldworks now?

2:49

Well, originally out of college, I did

2:52

an internship distilling and I thought I wanted to go down

2:54

that route and make whiskey and

2:55

distill. But I quickly

2:58

found out that that wasn't for me. There's not enough.

3:01

The turnaround times are too long and it

3:03

wasn't as much creativity as I wanted. So I

3:06

got a job working at a

3:08

small brewery and I was doing some sales stuff and

3:11

kind of helping out here and there in production. And

3:14

over time I slowly took over more and more and

3:16

more of production to where I became pretty

3:19

much the only person doing production

3:22

at that brewery. After that

3:24

stint there, I was there for about three and

3:26

a half years. I went to Black Project,

3:30

Spontaneous and Wild Ales down in Denver,

3:33

who unfortunately has closed. And I was the

3:36

production manager there for

3:39

I think it was about a year and a half, maybe a little,

3:41

a little under two, two, I

3:43

think two years there. And then I

3:46

came up to work at Weldworks and I was

3:48

hired on originally, as

3:54

a, it's kind of a weird thing. I

3:56

interviewed for a senior brewer position

3:59

and me. And another fellow

4:01

by the name of Derek Gold, both

4:04

were hired for the lead,

4:07

it was lead brewer, lead brewer job, but

4:10

Derek was the better fit for lead brewer, so they hired

4:12

me on as just, we'll figure out what he does.

4:15

And so I became known as the special projects

4:18

person, so I would

4:20

do research and development, I'd do all sorts

4:22

of different things, I'd work with the barrels,

4:25

do some of those things, and

4:27

then slowly I took over the barrel seller,

4:30

and then I was, my title at that point

4:33

was, wooden seller innovation

4:35

lead, something crazy like that, so I was

4:37

working on kind of finding out the

4:39

next innovation, what we were gonna do, and then that

4:42

kind of transitioned into me taking

4:44

over as head brewer, so I'd do a lot of the

4:46

tank scheduling. And Derek, who,

4:49

like I said, started at the exact same time as me, who

4:52

got the job over me for lead brewer, is now

4:55

our senior director of brewing operations,

4:57

so together him and I kind of come up

5:00

together at WeldWorks, we're almost

5:02

at our five year mark, we started a week

5:04

apart, and we worked

5:06

very closely together for the last five years, and

5:09

kind of, so that's kind of my

5:11

journey here at WeldWorks, and how I got here, and

5:15

I guess Neil trusted me to

5:18

take over as head brewer, and

5:20

those are quite the shoes to fill.

5:22

That's awesome, well congratulations to you. Thank

5:24

you, thank you. Were you ever into home brewing,

5:26

or did you start out with any formal education,

5:29

I guess, or?

5:30

Not brewing formal education,

5:32

I did go to college, but I did

5:34

quite a bit of home brewing. One of

5:36

my things that I wanted to do was, when I

5:38

was home brewing, is I really wanted to be a professional

5:41

brewer, and I would brew one

5:43

gallon batches of beer, and I'd brew

5:45

the exact same IPA recipe almost

5:47

every day. My goodness. And

5:50

one gallon at a time, and I would do it, it's

5:52

about six days a week, and then on the seventh day, I would usually

5:54

brew a five gallon batch of something different.

5:56

Wow.

5:57

And it was just, I wanted to learn.

6:00

consistency and that was the biggest thing that

6:02

I when I was reading everything I was reading

6:04

and learning self-ad self-taught

6:07

educated was Consistency

6:10

is the biggest thing to being a production

6:12

brewer And so that was my biggest

6:14

focus as a home brewer was being

6:17

able to brew Have a

6:19

six-pack of beer all from a different batch and you

6:21

not be able to tell that they were not brewed

6:23

the same day

6:24

That's a that's a good piece of advice because when I

6:26

started brewing I started brewing all these day Yeah, every

6:28

time I brewed I'd brew a different kind of beer, right?

6:30

And I finally figured

6:33

out it wasn't really learning much

6:34

by doing that, you know

6:36

You learn a lot

6:38

more by brewing the exact same thing time in and

6:40

time out and then I end up working

6:42

in a pretty big production facility that

6:44

makes juicy bits, you know

6:46

three or four times a week, so

6:49

Where it's it's very good to have

6:51

those that that that background and that set

6:53

of skills to be able to go Oh this this little

6:55

things off. Let's tweak this

6:57

It definitely picks teaches you how

6:59

to tweak recipes and and such. Yeah

7:01

Yeah, the other thing I found out is my beer never got any better

7:05

Again

7:08

Consistency comes from learning those little

7:10

those little things that you could tweak it. I think

7:13

I think I'm sure you make great beer

7:15

Well, yeah, this is many years ago, but

7:17

yeah So

7:19

I want to ask you before before you jump into stouts

7:22

talk about some of the innovation gone going as well

7:24

works I know one of your titles was innovation

7:26

manager at one time

7:27

Yeah, so one thing that we

7:30

always try to be innovative with and

7:32

stay Current with this hops

7:35

as a brewery that is, you know, we

7:37

do make a lot of barrel-aged stouts and we will talk

7:39

about that Like you said, but one

7:41

of the things that we've always kind of hung our

7:43

head on is our as our IPAs as well so

7:46

one of the things that we do innovation wise

7:48

is we're part of a lot of like breeding

7:51

programs and We

7:53

got to work with some of the So we're

7:55

actually a lot of them are in New Zealand, but

7:57

we're part of the Brax brewing program which

8:00

is a program put on by the NZ

8:03

Hops. And we're

8:05

part of their program, so we get to test

8:07

out some of their early hops and we have to write a bunch

8:09

of their descriptions,

8:11

help them with descriptions, help

8:13

them use it in commercial testing.

8:16

That's been a program that we've been a part of for two years

8:18

now since I started. Really enjoy

8:20

that. We recently were

8:23

added into Freestyle Hops, their

8:26

hop connection program. And

8:29

that's very similar, we were testing out some of the

8:31

hops for them in a commercial setting, getting

8:33

customer feedback, getting our

8:35

own feedback. It's, that's

8:38

really just been a really big, good

8:40

thing for us. We wish that more

8:43

brewers, we were able to do that with more

8:45

hop companies.

8:47

But yeah, so we've been working on that.

8:50

Another thing that we get to do is

8:52

work with yeast companies. So we've worked

8:54

with Omega Yeast Labs for quite

8:57

some time. They're our house

8:59

yeast strain. We're working with their, we're

9:01

gonna be one of the first people to

9:03

do a large commercial scale with

9:05

their new DKO, which is the diacetyl

9:07

knockout yeast strain. Oh, interesting.

9:10

Tell me about that. I haven't talked about diacetyl

9:13

knockout, although we did. We did have

9:15

Stan Hieronymus on a few episodes back talking

9:17

about New Zealand hops. He just returned from a trip

9:19

there. So probably working with me the

9:21

same companies you are, but. Yeah, probably. Yeah.

9:24

But tell us about the knockout hops.

9:26

Yeah, so the diacetyl knockout, the DKO is.

9:29

Yeah, yes, yeah. The diacetyl knockout yeast

9:32

is a new thing that, well, they've been working on

9:34

it for quite some time and we've had some of their tests,

9:36

but we're moving to it for a

9:38

full commercial use and

9:41

hopefully switch over our house yeast. So

9:44

what they've done is they've been able to genetically

9:46

modify their yeast strains

9:49

to produce the same enzymes

9:52

as ALDC, which

9:54

has become very common to be used

9:57

with hoppy beers, especially

9:59

the hazy ones. that we're seeing in HopCreep. So

10:03

to already have that enzyme in the Hop means that we

10:05

don't have to add additional product like the ALDC.

10:09

So we're pretty excited to test that out and see how

10:11

it works and see how, if it continues to

10:13

carry over generation after generation

10:16

and they're pretty confident with their testing

10:18

that it should work and we're really excited to

10:20

see that.

10:21

And I know it's- Is this the mainly fight HopCreep

10:23

then, I guess, or?

10:25

Yeah, it's the fight HopCreep

10:27

and just help with lower,

10:30

some of the British strains of

10:32

yeast do produce a little bit of diacetyl.

10:35

I think it's pretty common to taste a

10:38

small amount of diacetyl in

10:40

most hazy beers, but as

10:43

somebody who absolutely hates it,

10:45

I would like to not have to worry

10:47

about it. And if we don't have to pitch ALDC and

10:49

yeast at the same time, it would be really

10:51

nice to just use one product.

10:55

But I know when we talk about innovations, the funner

10:57

things are talking about hops or phantasm

10:59

powder or some cool

11:01

new fruit or something, but the innovations

11:03

that are less glamorous

11:06

or stuff

11:09

like that are really exciting to me is something

11:11

like this DKO yeast. And I'm very

11:13

excited to be working with Omega and

11:16

hopefully the commercial scale

11:20

is everything that we hope it is. That's

11:22

awesome. Well, great.

11:24

Yeah. Well, today you wanted to focus on barrel aged

11:26

stouts. Why don't you tell us

11:28

a little bit about first the barrel aged stout

11:31

style and how it's distinct

11:33

from some of the other styles of stout people may

11:35

be familiar with.

11:37

Yeah. So, I mean,

11:38

usually most

11:40

breweries, I mean, I could speak on, so

11:43

WeldWorks does barrel aged stouts very

11:45

different than probably most people. You

11:48

know, the stout style is usually most people

11:50

just take an Imperial Stout and then age it in a barrel

11:53

for a different period of time. At

11:56

WeldWorks, we actually treat the barrel as

11:58

an ingredient.

11:59

So... when we're, when we're

12:02

the media noche that you taste in the market,

12:04

which is our barrel aged out, um, is

12:06

not, you'll never taste a non barrel aged version

12:08

of that beer. Cause we're, we, we treat the wood and

12:10

the time spent in there as an ingredient. So

12:13

it's a lot, uh, we, we aged a lot

12:15

longer, but, uh, we make it

12:17

different, very different beer. So we do three,

12:19

uh,

12:20

three matches on our,

12:22

and on our stout and a very

12:24

extended boil. So anywhere from 20 to 30 hour

12:27

boils is what we're doing. Wow. Why

12:29

do you do the complex mass schedule and boils

12:32

in there?

12:33

Um, so the biggest reason is we want to have

12:35

a very viscous product. Um,

12:37

that's like the biggest thing we don't,

12:40

I mean, clearly the easiest way to reach

12:42

these high, um,

12:44

starting gravities would be to,

12:47

um,

12:48

just add sugar, you know, add, we could add

12:50

simple sugar. We could add complex

12:52

sugars. We got LME DME, any of those kinds

12:54

of things to, to, to reach this

12:56

high. Just like, just like us, we

12:58

have, you have limitations on what you can put in the mass ton,

13:01

right? Sure. Right. And, and, and

13:03

we have limitations of how much grain we can put in. And,

13:05

and, and, you know, when Neil was writing this recipe and

13:07

coming up with how he wanted to approach

13:09

barrel aged stouts, um, he did not want

13:11

to add sugar in at all. And we wanted to

13:13

all be a hundred percent from grain. Um,

13:16

and that's kind of just the

13:18

mindset and the mantra that

13:20

we, we, uh, follow here. So

13:22

we've just carried it on. Um, and when I say high

13:24

gravities, um, I'm talking like 30

13:27

to 40 Plato starting gravities. So,

13:29

I mean, like we're talking monster monster

13:32

beer.

13:32

Um, yeah. That's a,

13:35

what's the alcohol on that? It's gotta be quite high. It

13:37

really depends. Um, so some fermentations

13:40

are clearly better than others. And that's something that you

13:42

don't have to deal with when you're looking at over 1100 starting

13:46

gravity. Is that right? I

13:47

do. Yeah. Yeah. Yeah. Um,

13:50

uh, but yeah, so we're looking at like, um,

13:52

1120 is what, what I

13:54

rough number is. Yeah. Play that gravity.

13:57

Yeah. So, um,

14:00

What, uh, sorry, what was the question?

14:02

Oh, I was saying you started, you started like an 11, 20 starting grave.

14:05

It's quite high, right? It's a right. Yeah. So

14:07

probably 11, 12% beer or something like that.

14:10

Yeah. So our, our ABVs are anywhere between 12

14:12

and 13. We've had some, uh, if

14:15

we add in, you know, coconuts or something

14:17

and say later on, um, they,

14:20

they might go down to 10. Yeah. We

14:22

usually say the safe, safe bet. They're going into barrels

14:24

around 12 to 13. Wow. We've had some

14:26

up, up into the 16 range. Um,

14:28

the 16 range ones usually get blended back

14:31

with something a little bit, um, lower

14:33

gravity from our barrel stock, but, um,

14:35

just cause 16% we think is a little too

14:37

high. Yeah. Yeah.

14:39

I mean, you're almost at a barley wine, but correct.

14:42

Exactly. Yeah. Yeah.

14:44

So, um, so you really start with

14:46

a giant Imperial start still, right? But you're,

14:48

and you're going through a long, now you did

14:50

talk about the long boil and I guess you're using

14:52

that to get the,

14:54

to get to where you want in gravity, right? Uh,

14:56

with, with a fairly, start fairly, uh,

14:58

lower, much lower starting match gravity probably.

15:01

Um, but what are you doing? You mentioned

15:03

a melt, multi-step mash or something like that as

15:05

well. Um, so we're, so we're doing three separate matches.

15:08

So we'll do on the first day, we'll

15:10

mash in of turn.

15:12

Um, we'll, you know, do the standard

15:14

mash rest and then, um, from there we

15:16

will, we'll do what we call rinse instead

15:18

of a full on sparge. So we'll rinse, um,

15:21

for about, uh, you know, a quarter

15:23

of what our normal sparge volume would be. And

15:25

that's just to make sure we're pushing all the sugars

15:28

out of the mash ton and we'll run that into the kettle.

15:31

And then as soon as that's done, we'll get the, the grains

15:33

out and then we'll start a second mash

15:36

and then that'll get us up to our kettle up and we'll do the

15:38

same thing. Well, we might sparge a little bit longer

15:40

on that one. We'll probably go closer to half the

15:42

volume on the second, um, sparge.

15:45

So that way we get up to a, a, a

15:47

kettle volume that we can boil overnight

15:50

without it, um,

15:51

you know, going too low or, you know, so,

15:54

so we'll, um, we'll do that and then we'll boil

15:56

it overnight. And then the next morning we'll come in and we'll

15:58

run and add a hundred. 100% normal mash.

16:01

And those are usually, we're maxing out our mash ton

16:04

each time. So that's around 1800 pounds

16:06

of grain

16:06

per mash. Gee,

16:09

yeah, that's quite a process. And then

16:12

you mentioned boiling for almost 20 hours and you're concentrating

16:14

that work way down to get

16:17

the high gravity you want.

16:18

Right, and so what we've seen for the most

16:20

part is we have shortened it. It originally

16:22

was 36 hour boils. We've slowly

16:25

shortened them. I mean, clearly the

16:27

stuff that you're boiling overnight is pretty much

16:29

unferminable. So that's why

16:33

we do the third mash on the second

16:35

day. And that's basically where most of our fermentable

16:37

sugars are coming from. Right. And

16:40

that's why we treat it like a normal one. So we have this huge

16:42

concentrate of like

16:45

basically syrup, for

16:48

lack of better terms, a syrup

16:51

that's that boiled overnight. And then we

16:53

pump in the fresh runoff

16:56

to make something fermentable.

16:59

Yeah, I would imagine there's some effect

17:01

for boiling it that long, right?

17:03

Correct, correct. Caramelization and

17:05

so on going on, right? Yeah, correct. Yeah,

17:07

interesting.

17:08

Okay, so what does

17:10

the grain bill itself look like? What's the composition

17:14

to get this big and pretty stout? Yeah,

17:16

so our grain bill is, it's

17:19

a little bit more complex than probably it needs

17:21

to be, but we, you know, base

17:23

is just pale.

17:24

We also, we use

17:26

a lot of different chocolate malts. So we use

17:29

regular chocolate malt, we use chocolate rye,

17:31

we use pale chocolate, which is my personal favorite.

17:34

I recommend anytime that we do a collapsed out,

17:36

we always try to include

17:38

pale chocolate. And of

17:40

course the pale chocolate's on the edge of that harsh

17:42

zone, so you're getting some of that complexity too,

17:44

right?

17:45

Right, correct. And then we use

17:47

a mix of different crystal

17:49

malts. So it's usually 40, 60,

17:54

and then the equivalent of 150, I

17:57

think that it's the DRC from.

17:59

another one of those harsh malts, you know, kind

18:02

of like a special, probably close to a special B, right?

18:04

Correct. Yeah. And then, um, we do use

18:06

roasted barley. Um, but that one

18:09

that we use in such a low amount that I don't

18:11

even really consider us like,

18:13

cause because of how harsh roasted barley can

18:15

be, we use, um, it's less than a bag

18:17

between all three turns. So, and

18:20

then we use a little bit of Carafa special

18:22

to, which is also a little bit harsher. Um, but

18:25

that's, that's pretty much the, the,

18:27

um,

18:29

what we use, um, like I said, the

18:31

ratios, uh, we get a little

18:33

more specific if we wanted to, but it's mostly

18:36

pretty low. Um, but the, the chocolates

18:38

we go pretty high on.

18:39

So how, uh, so what percentage of specialty

18:42

malt overall, you're running like 10, 20% somewhere in the,

18:44

close,

18:47

close, closer to 15. Yeah.

18:48

Yeah. That's still, still, still quite

18:50

a bit of special. Yeah. Especially

18:53

when we're doing three turns, it's, it's the flavor going. Yeah.

18:56

I will say that, uh, we are not the most efficient,

18:59

um, people when it comes

19:01

to barrel aged doubts. Um, I like

19:03

to say that we make irresponsible barrel aged

19:05

doubts. Yeah. Yeah.

19:07

Uh, what about the hops? What are you doing for hops?

19:10

Hops? We're just doing, uh, after, so

19:12

after the full boil, um, we'll

19:14

pick a, you know, whatever time we're set for,

19:17

uh, within 60 minutes,

19:19

we'll add in a little bit of just,

19:21

uh, magnum, uh, just to get

19:23

a bitterness, uh, usually ends up being around 50

19:25

to 60 IBUs, depending

19:28

on if they're actually dropped right at

19:31

all that high for the gravity you're using probably. Right.

19:33

Correct. It is fairly, fairly

19:35

low considering that's probably true to

19:37

like a normal Imperial or Russian Imperial

19:40

style that even might be low for that style

19:42

as well. So, um, it's, it's, it's,

19:44

it's fairly low. Um, but it's,

19:47

it's, uh, yeah, most

19:49

of the times they probably, because like I said, we're boiling

19:51

for so long, it probably goes in closer

19:53

to 90 minutes or even, you know, 120. So it, it,

19:57

the bitterness kind of fluctuates depending on when

19:59

the hops are actually.

19:59

dropped by whoever's brewing. Yeah,

20:02

yeah.

20:02

Are you doing anything special with the water? Are you using

20:04

a special water profile? No,

20:06

we're not doing anything with the water. We might

20:10

add some baking soda to the mash

20:12

prior, but that's really rare. That's

20:14

kind of something we do with more of our

20:18

Imperial stouts and milk stouts rather

20:21

than our barrel aged stuff.

20:23

And then what about yeast and

20:25

fermentation? How are you managing the initial

20:28

fermentation?

20:29

Yes. So you got a very high gravity starting,

20:31

you know,

20:31

correct. Yeah. So one of the hardest things is

20:34

actually with such a thick and high gravity

20:36

beer is getting the correct oxygen

20:38

into it. So we

20:41

try to run it off slow. But like

20:44

I said, our oxygenation stone has

20:46

struggles pretty hard to get in.

20:49

So it kind of, you see bubbles of, of

20:51

O2 going through it rather than, you know, a normal,

20:54

you see little streams of small bubbles.

20:56

Sure. In our challenge giant

20:58

bubbles going through. So it's pretty hard for

21:01

us to hit those, the

21:03

same oxygen. So we do pitch

21:06

quite a bit more yeast.

21:08

We're putting in a 15 barrel batch, we're putting

21:10

in, I think it's three kilograms

21:12

of yeast, which is about double

21:15

what we do on a normal stout or

21:17

normal, or normal, you know, us O5

21:19

is what we're using for that dry yeast. And

21:22

that's just because we can't repitch it. So there's

21:25

no point in using, you know, something wet

21:27

or

21:28

kind of keep the costs on that part.

21:30

So you're using us, us O5. And I remember off the

21:33

top of my head, but is it a high gravity? Is it tolerant

21:35

alcohol tolerant? It

21:38

is tolerant enough for what we're trying to accomplish.

21:41

Like I said, we have gotten up into the 16s before

21:44

or 16% ABV. Yeah. There's a

21:46

lot

21:47

of, a lot of beer. Yeast won't

21:49

tolerate that much alcohol. Right. And

21:51

yes, for some reason it's worked for us, the

21:53

USO5. But like I said, we're already dealing

21:55

with a really hard

21:58

beer to ferment anyways. And when we...

21:59

When we're doing collabs, we tell people these things,

22:02

they're like, well, how much attenuation are you seeing? I

22:04

said anywhere from 60 to 40%, depending

22:06

on what the beer is and how healthy

22:08

it is. On stuff, when

22:11

we're up in the 40 plateaus, which again,

22:13

we don't do those very often. We

22:15

do probably one batch of those a year, just

22:17

as a blender for extra,

22:19

just for different projects. But what

22:22

we're usually looking for, or sorry, on

22:24

those higher ABV ones, the next day, usually

22:26

day two, we're actually going to add more oxygen

22:28

into the bottom of the tank. That's one of the questions I

22:30

was going to ask you. It's very common of

22:32

high gravity meats, high gravity wines,

22:35

even some high gravity beers to add a second dose

22:37

of oxygen at 12 hours

22:38

or so. Are you doing that

22:41

as well?

22:41

Yeah, usually somewhere between 12

22:44

and 24, sometimes maybe twice in

22:46

that timeframe. We

22:49

do treat it more like a wine or a meat

22:52

because of that.

22:53

And

22:54

again, I'm not really scared of, because

22:57

we're going to put it into a barrel, I'm not scared

22:59

of oxygen

23:02

ingress occurring at

23:05

any step of the process.

23:06

I'm sure we'll

23:08

talk about that when we get into the actual barrel.

23:11

Yeah, but with a high gravity beer, actually the oxygen

23:13

doesn't really hurt it that much. Correct,

23:16

correct. At least in the first 24 hours

23:18

or so, and it can still process

23:20

a lot of that and

23:22

absorb a lot of that oxygen. It

23:24

almost none of it will end up in the finished beer.

23:26

Exactly. Overall,

23:30

that's kind of what we're looking at. But like I said, the

23:32

fermentation is about

23:34

as rough as we probably would like it in

23:36

our brew

23:39

house. It's the only beer that we accept for

23:41

fermentation

23:42

parameters.

23:47

If it's a little bit rocky,

23:49

if it's slow, if it's...

23:51

That's the only one that we kind of just let it do

23:54

its thing. Do you do anything special with the yeast,

23:56

like preparing it? Because one

23:58

of the big concerns with the gravity of that...

23:59

is osmotic shock, which is where you take

24:02

yeast cells, especially

24:04

dry yeast cells, and throw them right into a very high

24:06

gravity beer and you have problems. Do

24:08

you take some time to acclimatize the yeast before

24:10

you pick it?

24:11

Nope, nope, we do not. Nope, it's kind of one

24:14

of those things where. One of those things you might wanna

24:16

try in the future. I don't know. No, no, no, we

24:18

have tried using liquid yeast and

24:21

different things and harvested yeast from

24:24

second generation yeast. But

24:26

honestly, what we found is kind of like, don't fix

24:28

what isn't broken type thing. And I know that

24:30

it's not the

24:33

best thing to say, but it's just, we've

24:35

tried these other things and they've kind of come

24:37

to the same conclusion. And even some of the second

24:39

generations have actually petered out

24:41

when we've seen USO5 continue forward.

24:44

Yeah. So as weird as it sounds,

24:46

for some reason it just works. Well,

24:49

maybe the USO5 is more tolerant, I don't know. Yeah,

24:52

I mean, USO5 is a workhorse and

24:54

I would recommend that for anybody who's

24:56

just doing anything that you don't need

24:59

flavor from yeast. We

25:01

use that yeast quite a bit in house.

25:04

So do you let it, do you have a particular temperature

25:06

profile, do you let it free rise? Do you

25:08

just hold it to kind of a mid

25:11

range temperature? Yeah, we're usually around 68,

25:14

which is optimal for USO5. And

25:17

we just kind of let it do its thing there. And

25:19

fermentation temp is, yeah, it's pretty standard.

25:22

We don't really have to worry about diacetyl

25:24

too much in this.

25:27

Usually we don't see too

25:29

much diacetyl, but even if we did through the extended

25:32

aging, that kind of goes away

25:34

anyways. But we do keep it in

25:36

the fermenter for 20 to 22 days.

25:39

So that's a good period of time to let

25:42

it age out, right? Yeah, correct. And I seem

25:44

to be pulling it off the yeast at that time as well.

25:46

Correct, we're constantly dumping yeast

25:49

pretty much daily, dumping off the bottom.

25:52

Sometimes we'll do a little bit heavier. I mean, right

25:54

before we go into the barrel, we're clearly gonna do a

25:56

really heavy dump on it. But

25:58

yeah, so try. trying to get as much yeast out. It

26:01

will crash around day 20, usually

26:03

goes into barrels around day 22.

26:05

Wow, so it does go directly into the barrel then

26:08

from the fermenter, huh?

26:09

Correct, yeah.

26:10

Interesting.

26:11

And you just do that based on time,

26:13

I guess 20, 22 days roughly.

26:16

Yeah, usually it's basically, I mean,

26:18

clearly, usually by day 12 to 14, you're

26:22

seeing it's pretty much done fermenting.

26:25

And so the rest of it is kind of clean

26:27

up, make sure some of the yeast drops out. But

26:30

yeah, for the most part, we make sure it's

26:32

stable clearly before we're putting it into the

26:34

barrel. If it's still

26:36

fermenting, we can hold it out longer in the tank

26:38

until it's done. But we've never, at 22

26:41

days, we've never seen, or even day 20,

26:43

we've never really seen fermentation moving in

26:46

a beer that sweet.

26:48

That's cool. That's awesome. Well,

26:51

I guess we ought to move on to barrels now. We could easily

26:53

take up a whole show talking about barrels. Yeah.

26:57

But what type of barrels are you using just sort

26:59

of at a base level and how are you

27:01

managing them over time?

27:03

Yeah, so we use,

27:06

90% of our barrel warehouse is bourbon

27:09

barrels. Usually oak, just

27:15

American, Kentucky bourbon barrels. We

27:19

get them from all over America, but mostly Kentucky. And

27:23

the organization of that is quite a

27:26

task. I would imagine.

27:29

So at our biggest, we had 650 oak barrels

27:33

filled in our warehouse. And we

27:35

sit around around 350-ish now. That's

27:39

kind of where we found as our sweet spot. So it's quite

27:41

the tasks to make

27:44

sure we're keeping eyes on all of them. But we

27:46

have a spreadsheet that

27:48

has a lot of hard data on

27:50

it for each barrel, with

27:53

stuff like ages, gravity, starting gravity,

27:58

calculated alcohol. I like to say,

27:59

because we haven't ran it through our Alkalizer

28:02

prior to going into the barrel. Right.

28:06

You know, batch numbers, all

28:08

that kind of stuff. And then each barrel itself

28:10

has similar data printed

28:12

in a sheet hanging on the front of it. So that way we can walk

28:15

through and look at stuff and look

28:17

at those numbers. Spreadsheet

28:20

clearly with, you know, how long

28:22

it's been in there is a little bit more accurate because it can

28:24

automatically update itself to tell you it's at blah,

28:27

blah, blah month instead of doing the math, but math

28:30

is fun too. And

28:32

then for kind of managing

28:34

it, we do have a dedicated warehouse

28:36

that does have humidity control for the wintertime.

28:39

Since we live in Colorado, our winters are extremely

28:42

dry. So it does have humidity control for

28:44

winter. And then it also has heating

28:47

and a little bit of air conditioning. The

28:49

air conditioner does go out sometimes, which

28:53

is okay. I'm a very, I

28:55

kind of adopted this philosophy from Neil

28:58

when he was kind of overseeing all the barrel

29:00

stuff. And it's to kind of let it go through

29:02

the seasons. We want it to experience the

29:04

changes of the season. Clearly

29:07

the heater in the wintertime

29:09

is just so we don't freeze. It

29:11

doesn't really, I wouldn't say the room can

29:14

be warm and some of the barrels will get warmer than others.

29:16

But the biggest thing is we want to make sure that we

29:18

are keeping them from

29:21

freezing. And that's 100 percent it. We want to see

29:23

it go through the cycle of

29:25

every season and in the

29:28

winter, it's contracting

29:30

and pulling the beer into the wood

29:32

versus the summer. It's kind of expanding

29:35

and spitting the wood out. So we

29:37

want to go through those cycles of going in and out

29:39

of the wood. That's something that's really big

29:41

for us. But twice a year,

29:43

we are going in two to three times, sometimes

29:46

more. We're going in and we're reorganizing

29:49

all of the barrels to make sure that they

29:52

are in a certain order that we have. So that

29:54

way when we go to pick them for blending

29:56

stock and to actually produce the final

29:58

products, we're able to. to get to

30:01

the ones that we need to as easy as possible and not

30:03

lifting through all of the brand new filled ones

30:05

first. Um, and all the old ones are in the bag.

30:08

Cool.

30:09

Um, before we dive into that, how, how do you

30:11

manage the barrels themselves? Are you reusing them

30:14

multiple times? Uh, are

30:16

you, um, you

30:17

know, how do you manage the barrels from batch to batch?

30:20

Yeah. So, um, we are only currently

30:22

using barrels one time per, single

30:26

use. Yeah. Single use. So it does add a little bit of

30:28

cost into, um, the way that we're doing, but like I said

30:30

earlier, um, I would say we're very irresponsible

30:33

with how we produce barrel aged out.

30:35

Um, but, uh, we

30:37

do use them once. Um, if they come in and they're a little dry,

30:39

we will, um, hammer the,

30:42

uh, we'll do a hoop hammer on them and, uh, hammer

30:44

the hoops in place a little bit more. Um, and

30:47

then we'll do something called a bird bath, which is where you're going

30:49

to put eight, um, hot water, hot liquor,

30:51

uh, whatever you want to call it on top

30:53

of the barrel, um, on the barrel head,

30:55

and that'll help swell the staves around it and

30:58

kind of get it back to tight. Um,

31:00

we do not put any liquids in

31:02

the barrel. Um,

31:04

just so that way we're keeping that bourbon flavor. Um, since

31:07

we paid for the bourbon flavor, uh,

31:10

and the oak flavor, we want to see

31:12

that come through in the final beer. Um,

31:14

so by, by rinsing it with hot, hot

31:16

liquor or hot water or whatever, like I said, whatever you

31:18

want to call it, um,

31:20

you, you know, you're going to remove some of those flavors

31:23

and the biggest thing is to try our hardest to

31:25

keep those flavors intact until

31:27

they can reach the beer. So, um, the

31:29

goal would be to not do anything at all to

31:31

the barrels, but sometimes they come in in a little

31:33

bit less than ideal shape.

31:35

So we have to, yeah, I mean, you also can't leave them

31:37

dry very, very long either, right? Correct, correct,

31:40

correct. Yeah. You got to use them pretty quick when they come

31:42

in, I would think. Yes. Yeah. We, we, we

31:44

the longest we usually try to leave the things empty

31:46

would be three months. And that depends on how long

31:49

they've been in a warehouse prior to, um, we

31:51

work with a lot of people that get us barrels really

31:53

quickly. Um, and the, our,

31:55

our brokers have been really good to us. So, um,

31:58

we usually get them within a couple of weeks of them getting. them.

32:00

So that gives us that three month window. Um,

32:03

if they've had them in their warehouse, it's, they

32:05

usually let us know how long they've been. And then we'll adjust

32:07

our production schedule to fit,

32:09

um,

32:10

to make sure that we're not leaving them empty from

32:12

the distillery to when we fill them for longer

32:14

than three months. We will make exceptions,

32:17

but we try not to.

32:20

Now I'm managing the barrels as there, as

32:22

you're going through, uh, aging, do you, uh,

32:24

do you top them off as you go? Do you,

32:26

uh, how do you, how do you handle that?

32:28

Cause obviously you lose a little bit of volume

32:30

over time.

32:31

Yeah. So, um, we do not top

32:34

off our barrels. Um,

32:36

it's partially because, uh, we

32:38

don't in Colorado, we don't lose a terrible

32:40

amount. Like I said, it's dry, but the way that

32:43

it works is that we're actually at an altitude

32:45

to where we're actually not losing as much angel

32:47

share as say somebody may be in Texas

32:49

or somewhere else. Um, so because

32:51

we're not losing it, we're not, um, you

32:54

know, we're not super worried about keeping it. The

32:56

other thing that, uh, this is a personal belief of

32:58

mine and that's kind of how we've done the barrel age

33:01

program is, um, we're not really worried about

33:03

oxygen ingress at all.

33:04

Um,

33:05

we move our barrels when we have to move them, we

33:07

don't top them up. If we didn't want

33:10

some oxygen character, ox, you

33:12

know, um,

33:13

oxidized character in the beer, we wouldn't

33:15

put it in a barrel. Um, yeah.

33:17

The nice, the nice thing about getting a little bit oxygen

33:19

and something like an Imperial stout, it's going to add more

33:22

of a Sherry type finish to it. And so

33:24

instead of the paper cardboard thing, right?

33:26

That's right. And, and, and that's the big

33:28

thing for us is that, I mean, we make a sweet product

33:30

on purpose to hold up to those, those, those

33:33

oxygen, uh, ingress and,

33:35

uh, those, those flavors that come from, come

33:37

from that. And, uh, the biggest thing

33:40

for us is that it's part of our belief. And, and I,

33:42

I know people get really worried about their

33:44

barrel aged outs, getting too much ox oxygen.

33:46

And, and it's just not something we worry about. And, um,

33:49

like I said, if I was super worried about it, I wouldn't have put it

33:51

in a barrel to begin with. That's not something

33:54

that keeps oxygen out. So, uh,

33:56

instead of fighting it and trying to,

33:58

you know, I've heard of people. like, oh, they purged

34:00

the barrel before they fill

34:02

it with stout with, they purged with CO2. And

34:05

I'm just like, I don't understand because by the time

34:07

you're done, I mean, move

34:10

it into the resting space. It's that all that space

34:12

is oxygen again. Anyway, it's just, like

34:14

I said, I, that's, that's one of those things that I've always

34:16

kind of seen. Like I'm on the outside, um,

34:19

of the overall, um, Brewers

34:21

or professional brewers. Uh, when I

34:24

say that I don't, I genuinely don't

34:26

fight it. I embrace it. I like oxygen,

34:28

um, being involved in our

34:30

barrel aged stouts. Yeah.

34:32

Um, well, how do you go about determining when the beer's

34:34

done? Uh, do you have a certain amount of time

34:37

that you work with, uh, you know, leave it in the barrel

34:39

or, or do you taste it periodically? How

34:41

do you manage that?

34:42

Um, so the first thing is that we have

34:44

an 18 month minimum and that was kind of just

34:47

based off of, um, the initial

34:49

tastings that Neil had done with these

34:51

beers over time. And so

34:53

we won't taste anything before 18 months.

34:57

Um, and then when we're going for a project,

34:59

we're more looking to fill what

35:02

our project did demands. Right. So

35:04

if we're just doing a non-adjuncted

35:07

barrel aged stout, um, then we're

35:09

clearly, we're trying to blend for a flavor

35:11

profile that we have in our head. Um,

35:14

or blending because we want to

35:16

use, like, let's say we have our, our W12,

35:18

which was aged in all well or 12 barrels. Um,

35:21

we're going to blend those to kind of fit what

35:23

we think, um, does a really good job

35:25

of showcasing the well or 12 flavors. So

35:29

you say, and then, um, go ahead. I'm sorry.

35:32

Well, yeah. So, so we're, we're, we're, we're 18

35:35

months minimum, but, uh, we kind

35:37

of blend for the project. So yeah.

35:39

So are you tasting it periodically

35:41

then after the 18 months to maybe say, okay,

35:43

this is kind of in the ballpark or what?

35:46

No, not really. We're, we're like I said, we're more

35:48

tasting dependent once a project

35:50

has been put on the plate and we go through, we look through

35:52

the spreadsheets and kind of feel out what

35:54

we're looking for. Um, and before

35:56

we walk into a room full of 350 barrels. Let's

36:00

say if we have 350, there's probably half

36:02

of them are above that age. So I don't

36:04

need to go through and taste 150 plus beers, 175 beers

36:06

of barrels to do that. So

36:12

we have to kind of narrow it down based on

36:15

our knowledge of what those beers taste like. I

36:17

mean, at this point we've been doing it for seven years.

36:20

So we know kind of what a gravity

36:22

plus a pH plus that barrel,

36:26

what that will do over time. So we

36:28

have a starting point. We kind of look at

36:30

that starting point. We pick out barrels based

36:32

on that, and then we'll go to that stack and

36:34

we'll taste through probably that

36:36

stack of barrels and then go, okay, these two are

36:38

really good. Let's mark them. And then that's

36:40

it for the day. And then we go do it again. But again, when we're

36:43

talking about blending huge

36:45

amounts of barrels, it makes it really

36:47

hard to just go in and taste a ton of barrels.

36:50

I say after three or four, maybe

36:53

even maybe if you're lucky, you get

36:55

five really good tastes in before you

36:57

blow out your palate and you can't taste

37:00

as accurately as you were at the beginning.

37:02

Yeah, especially, especially at that alcohol level,

37:05

right? Correct.

37:06

Yeah. So you mentioned blending a number

37:08

of times. I assume you're doing, you know, you are

37:10

blending the beers in some way. Is there any kind

37:13

of rule of thumb you use for determining

37:15

what the blend you blend good with bad? You

37:17

only blend good with good. How do you work in that?

37:19

I mean, so yeah, sometimes

37:21

you want to blend in. I mean, so

37:24

the thing with bad is

37:25

bad is

37:28

so subjective. As long as you're not

37:30

talking about all flavors, right? Yeah.

37:32

Yeah. Yeah. So

37:34

just because I like something might be more roasty and like

37:36

to me, a heavier roasted imperial

37:38

style might not be as good as say like

37:41

a smoother chocolatey or one.

37:43

But that doesn't mean that together they make something really

37:45

great. So yeah, it's just again,

37:48

it mostly depends on what the project is. If we're

37:50

going to add coconut to a beer, I'm

37:52

looking for stuff that has really big coconut

37:54

from the wood flavors or from the spirits,

37:57

which does happen quite a bit. Vanilla is another. flavor

38:00

profile that you're gonna see a lot in our barrels.

38:03

So we're just kind of looking for that. But

38:05

yeah, if we get lucky

38:07

and all of them are deemed really like

38:10

grade A, class one, best

38:12

of the best, and we can make a blend with that, of

38:14

course I'm gonna do that. But

38:16

you know, like I said, each one is gonna have its own little,

38:19

maybe what I call flaw.

38:22

But it's not necessarily a flaw, it's

38:24

just like, oh, this stands out a little differently than

38:26

this. But if we do find a barrel

38:28

that's like, hey, this barrel right here is something

38:31

special, we'll take that barrel and release

38:33

a single barrel. Usually it's draft only, and

38:36

we'll release something special with that, with that

38:39

really cool, unique

38:42

flavor profile, or just this is grade

38:44

A example of what we want.

38:46

So can you combine certain flavors, maybe

38:48

to make a better beer in the end?

38:50

Sure, yeah. We do that all the time. And that's usually

38:52

the goal of our blending, is to take

38:55

a bunch of different elements and

38:57

put them together and make something nuanced

39:00

and complex that otherwise might be

39:02

more like, oh, this is just chocolate, or this one's

39:04

just roast, or this one's a ton of bourbon,

39:06

and this one's a ton of oak. But if you add

39:08

them all together, you can get all those flavors. And

39:11

I think the sums usually are better

39:13

than just the parts.

39:16

So you mentioned you had 350 or so barrels

39:18

in the program. Are they all barrel-aged

39:20

stout, or are you using them for other things like sours

39:23

and so on?

39:23

We currently have no mixed

39:26

fermentation. We do have a

39:28

couple of kettle sour, quick sours,

39:31

in barrels, but not much. Yeah.

39:33

And barley

39:35

wine, we have probably less

39:37

than 10.

39:38

Oh, wow. So it really is focused

39:40

on the stouts, I guess. Correct, correct.

39:42

It is really mostly focused on stouts.

39:45

Our barrel program pretty much revolves

39:48

around the barrel-aged stouts.

39:50

We were lucky enough to win. Within

39:53

our second year, we won a GABF gold

39:55

medal for barrel-aged stout, and then that same

39:57

year went on to win a... Festival

40:00

of Barrel Age Beers Gold as well, or

40:03

excuse me, a silver in that one. So we've

40:05

been lucky enough to win some awards for it and that kind

40:07

of pushed us into, well, let's

40:10

just run with this.

40:12

That's awesome. Well,

40:13

good. Yeah, thank you.

40:15

Well, what are some of your tips? Let's

40:17

take it down to the homebrew scale now for a minute. What

40:20

are some of the tips you might have for a homebrewer

40:22

looking to make a great barrel age

40:24

talent?

40:26

So the biggest thing would be working

40:28

on sourcing barrels. I know

40:30

that trying to fill a 53 gallon

40:32

barrel seems intimidating, but there

40:35

are some great ways to do that. There

40:37

are also great ways of doing smaller

40:40

ones that fit the size system. I

40:42

would recommend searching for local distilleries.

40:46

Some of the smaller distilleries, you're using smaller barrels

40:48

and they'll part with those.

40:51

And if you end up getting a big barrel and you're

40:53

in a homebrew club, sometimes

40:55

it's really fun to get everyone to brew a

40:58

five gallon batch or 10 gallon, whatever

41:00

their size system they're working with, whatever kit they're

41:02

on, and then kind of blending

41:04

them all together and putting them in the barrel. And instead

41:07

of emptying all 53 gallons, kind of make it into

41:09

a Solera project. And whenever

41:11

you empty out, you fill back up with

41:14

a new brew and that kind of becomes more easy

41:16

to keep going. Of

41:19

course, over time, you will lose some of that spirit flavor, but

41:24

I do think that working in a group of people is always

41:26

fun, having different systems and

41:28

maybe even different recipes adds complexity into

41:30

it.

41:32

There are plenty of websites that you can buy small

41:34

barrels on. Some of them don't have spirits. So

41:36

another thing I'd recommend, if you want the spirit

41:38

flavor, since you are homebrewing and you're not

41:40

selling this, you can add your own spirit

41:43

into it. So you could take a spirit that you personally

41:45

enjoy, have it aged in

41:47

that barrel for quite some time. Once

41:50

you take it, then you take the bourbon back

41:52

out or spirit back out and enjoy

41:54

a deeper barrel-aged expression

41:57

of one of your favorite spirits. That's

41:59

something that I enjoy. doing as a home brewer. And

42:02

then of course if you cannot get

42:04

any barrels, there's always oak

42:06

spirals or chips that you can play

42:08

around with to get some oak

42:10

flavor and that sort of thing.

42:13

But

42:13

that would be my tips is worried about mostly

42:16

of sourcing your barrels and

42:18

making sure that you're able to fill them to

42:20

start all the way to the top before

42:23

you let them rest. Again, you're going to lose some and

42:25

that is okay, but I think it's very important

42:27

to start all the way to the top because

42:30

you don't want to come out and empty your barrel and

42:32

it's only a quarter of the way full.

42:35

And I mean, do you recommend starting with a high gravity

42:38

Imperial Stout? Is that really the does

42:40

that seem like the base, the best base to

42:42

start with?

42:43

If you're going to try to reuse the

42:45

barrel, then probably not.

42:48

I think that if you do a high gravity Imperial Stout,

42:50

you're going to personally, I think you ruin the barrels. That's

42:53

why we don't clean them and use them again. But

42:55

if you want to do, I just grew a quick, why is that?

42:58

I was just wondering what the why

43:00

we don't know why. Yeah. Why how does

43:02

it ruin the barrels? I was kind of interested. I

43:04

mean, that dark flavor kind

43:06

of well, first off, we're aging are so long that there's

43:09

not much spirit flavor left and that's a big part

43:11

of what we're going for. Makes sense in our

43:13

expressions. So to reuse it, we're going to get a

43:15

lot of the oak, which is great. And I like oak, but we're

43:17

definitely want the spirit to be very

43:20

prominent in our in our final product. So

43:23

that's part of the reason. And then the second reason is

43:25

if we were to do a second beer, like let's say like

43:27

something lighter, a

43:28

lot of that,

43:30

like I said, when we're expanding and contracting into the

43:32

woods, a lot of that gets stuck in there and then it will

43:34

kind of taint the other beers and make them

43:36

a little bit darker than we probably wanted

43:38

them. So make sense. And

43:40

like I said, with us not doing very many barley wines

43:43

or or, you know, mixed firm or even,

43:45

you know, quick sour barrel aged

43:47

stuff, there's really no need for us to reuse

43:50

them without that spirit flavor. So

43:53

interesting. Yeah. Well, thanks,

43:55

Skip. I wanted to get where you are coming to the end

43:57

of our time, but I wanted to get your closing thoughts.

43:59

on on barrel aged stouts and

44:02

indeed you know anything you have to say

44:04

maybe his head brewer as well.

44:06

For me for barrel aged stouts and people

44:08

who want to try it at home I think the biggest thing is it

44:10

seems intimidating and I

44:13

would like to say it's really not and it's

44:15

really fun as somebody

44:17

who started in a distilling background I think mixing

44:20

those two worlds is really fun and

44:22

I think it's something that if it seems intimidating it's

44:25

not just remember you're making beer

44:27

it's supposed to be fun it's if

44:30

even if even if it turns out terrible you know

44:32

what try again I just can't

44:34

imagine if you if you do all the things that you know how

44:36

to do as a home brewer and get into a barrel

44:38

that's a good quality barrel you're gonna have a good

44:40

product at the end and don't get discouraged

44:43

if you don't on your first try.

44:45

Awesome also I almost forgot

44:47

but I wanted to give a chance to you mention your website

44:50

the location where people can find your beers.

44:53

Yeah so we're located in Greeley,

44:55

Colorado our website we

44:57

do ship merch all over the country we

45:00

don't ship beer but we do have distribution

45:03

all over the country right now. Okay. Since

45:05

we've been talking about barrel aged stout

45:08

we are releasing our second nationally

45:11

released I think it goes to 13 of our markets our

45:14

second barrel aged Imperial

45:16

Stout that will see distribution it's

45:19

our 2023 Media Noche and

45:22

that will be released I believe right

45:24

before GABF which is in September so I

45:27

think you'll see national by October

45:29

you should see it all over the country we're

45:31

very excited to share this again we

45:34

did our first national release earlier

45:36

this year and went really really well really well

45:38

received and we're really excited to bring another

45:40

beer barrel

45:42

aged stout to people all over

45:45

the country. I also want to give you a chance

45:47

to mention your headline beers because I know those

45:49

are white label juicy bits and some of the other

45:51

bits yep juicy bits is available in

45:53

all of our markets that we're currently in unfortunately

45:55

I don't know all of them off the top of my head

45:58

but yeah we're juicy bits extra extra juicy

46:00

bits should always be available rotating

46:02

through stuff. Our seasonal,

46:05

we do our quarterly beers coming up. We're

46:07

gonna have Peach Pie and Trans Mountain Diversion

46:09

is our double IPA. Peach

46:11

Pie is a sour and Trans Mountain

46:13

is a double IPA, like I said, brewed with our good

46:16

buddies Casey Brewing and Blending

46:18

up in Glenwood Springs, Colorado. And

46:20

we're excited to be able to bring those to

46:24

people all over the country for a whole quarter

46:26

of the year. Trans Mountain happens to be one

46:28

of my favorite IPAs we do every year. So

46:30

I'm glad that we get to get it out all

46:32

over the place.

46:34

Awesome Skip. Well thank you so much

46:36

for coming on the show today. Really appreciate you being here.

46:39

Hey thank you for having me. I enjoy talking

46:41

about barrel aged stouts so glad

46:44

you had me on to do it.

46:45

Awesome. Well today my guest was Skip Schwartz.

46:47

He's the head brewer at Weldworks Brewing.

46:50

Thank you again Skip.

46:52

Thank you. A

46:54

big thank you to Skip Schwartz for joining me this week.

46:57

Thanks also to Craft Beer and Brewing Magazine.

46:59

They offer access to videos, brewing

47:01

courses, exclusive articles, and the amazing

47:03

Craft Beer and Brewing Magazine.

47:05

Go to BeerandBrewing.com to get your subscription

47:08

today.

47:09

And also the American Homebrewers Association.

47:12

The Homebrewers Association invites you

47:14

to choose your own brew venture. Join

47:16

for one year and select a free brewing book

47:18

for more than 60 titles to match your fermentation

47:21

goals. Visit HomebrewersAssociation.org

47:25

slash beersmith to join the Homebrewers Association

47:28

and treat yourself to a new brewing book.

47:31

And Beersmith Web, the online version of

47:33

Beersmith Brewing Software.

47:35

Beersmith Web, for the web, lets you design

47:38

great beer recipes from any browser including

47:40

your tablet or phone.

47:41

Edit recipes on the go with the same full suite

47:44

of recipe building tools as our desktop version.

47:47

Try Beersmith Web today by creating a free

47:49

account at

47:50

beersmithrecipes.com.

47:53

And finally a reminder to click those like and

47:55

subscribe buttons on YouTube, iTunes,

47:58

Spotify, or whatever platform

47:59

you listening on. Clicking those buttons is

48:02

a great way to support our show. I'd like

48:04

to thank you for listening and I hope you have

48:07

a great

48:08

Brewing Week!

From The Podcast

BeerSmith Home and Beer Brewing Podcast

The BeerSmith Home Brewing Show is a beer brewing podcast focused on how to brew beer, homebrewing techniques, and beer stories from top US and international brewers. In each episode we bring you an interview with guests assembled from around the world to talk about beer, craft beer and homebrew. The BeerSmith podcast is hosted by Dr Brad Smith, the author of BeerSmith homebrewing software, the book Home Brewing with BeerSmith, and the BeerSmith blog which attracts over 200,000 readers monthly. Website: http://BeerSmith.com/blogJoin Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

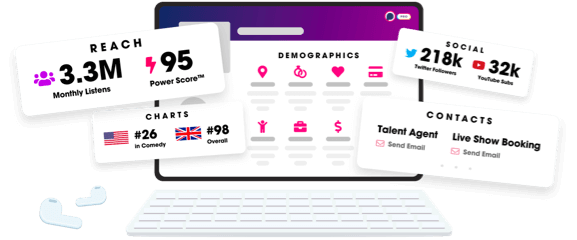

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us