Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:00

Jamil Zaynchev joins me for another brewing

0:02

question and answer session. This is Beersmith

0:04

podcast number 281.

0:16

This is the Beersmith home brewing

0:18

show, where brewing great beer

0:20

is our passion. If you want to take your

0:22

brewing to the next level, visit Beersmith.com,

0:25

where you can download a trial version of our Beersmith

0:28

software. Subscribe to the newsletter

0:30

and get dozens of free articles on home

0:32

brewing. And now your host and

0:34

the author of Home Brewing with Beersmith, Brad

0:37

Smith.

0:39

This is Beersmith podcast number 281 and it's late

0:41

May, 2023.

0:43

Jamil Zaynchev joins me this week for a question

0:46

and answer session. Thank you to

0:48

this week's sponsors, Craft Beer and Brewing magazine.

0:50

Every issue of Craft Beer and Brewing magazine

0:52

is packed with articles for home brewers and beer lovers.

0:55

They offer access to videos, brewing

0:57

courses, exclusive articles, and the amazing

0:59

Craft Beer and Brewing magazine.

1:01

Go to BeerandBrewing.com to get your subscription

1:04

today. And also

1:06

Beersmith Web, the online version of Beersmith

1:09

brewing software. Beersmith for the

1:11

web lets you design great beer recipes from

1:13

any browser, including your tablet or phone.

1:16

Edit recipes on the go with access to tens

1:18

of thousands of recipes,

1:19

as well as a full suite of recipe building tools

1:22

that our desktop version has.

1:24

Try Beersmith Web today by creating a

1:26

free account at BeersmithRecipes.com.

1:30

And finally, a reminder to smash the like and

1:32

subscribe button on YouTube, iTunes,

1:35

Spotify, or whatever platform you're listening

1:37

on,

1:38

as it really helps us in many ways.

1:41

And now let's jump into this week's

1:43

episode.

1:46

Today on the show, I welcome back Jamil Zaynchev.

1:48

Jamil is an award winning professional brewer and

1:51

home brewer.

1:52

He's authored the books Brewing Classic Styles,

1:54

The Practical Guide to Brewer Fermentation,

1:57

and he's also co-host of the Brew Strong podcast

1:59

on the. Brewing Network. Uh, Jamil, it's

2:01

great to have you back on the show. How are you doing today? I'm

2:04

doing great. Thanks for having me, Brad.

2:06

It's a pleasure. Absolutely. We always

2:09

enjoy having you here. It's been almost a year since

2:11

we last chatted. If you can believe that.

2:13

I, when you said that I, I

2:15

couldn't believe how time fly.

2:19

Well, I mean, are you enjoying a semi retirement

2:21

now?

2:23

Yeah, I'm semi enjoying

2:25

semi retirement. Yeah. You

2:28

mentioned you still have several projects going on,

2:30

I think a couple books or something.

2:32

Yeah. There's lots of books to

2:35

write still. I've, I've been a home

2:37

brewing a little bit during some, uh, uh,

2:39

classic British Ales, uh,

2:43

for to serve in my friend's, uh, garage

2:45

pub and, uh, yeah,

2:48

uh, fixing things around the house, which I really enjoy.

2:50

I like to see, you know, the

2:52

results of work and, uh, home

2:55

repairs. You usually go pretty quick. So

2:58

that's been a joy. Really? Mine always take

3:00

three or four trips to home Depot. I don't know about you,

3:02

but yeah. Yeah.

3:05

That happens too.

3:08

Well, uh, before we get started, I want to ask you, so

3:10

if you're home brewing again, what are you brewing on? What kind of system

3:12

do you have? Uh,

3:14

my good, good friend, Chris Graham from

3:16

more beer. He gave me a, uh, brew

3:19

Zilla, uh, all in one

3:21

system.

3:22

Yeah. And, uh, I'm surprised

3:24

at how easy and convenient

3:27

it is and how it stores in a small location.

3:31

Uh, it doesn't take up a lot of room and, uh, super

3:34

easy to use. Uh, so I

3:36

really like it. And like I said, I've been brewing

3:38

mainly British sales, so nothing really high gravity.

3:41

Um,

3:41

and the quality has been

3:44

fantastic. So I'm real happy with it.

3:46

Really, you know, he, he

3:49

was like, if you're gonna home brew here, I'll give

3:51

you, give you one. I

3:53

tell you, I have a 10 gallon system, but I've been tempted

3:55

to get one of those small all in one systems

3:58

just to be able to brew smaller batches. You know?

4:00

And like I said, just

4:02

super convenient. It's one vessel and

4:04

you do everything in the one vessel.

4:07

So, and it's got a pump.

4:10

It's got, you know, heater control. It's

4:12

got, you know, you can recirculate, you

4:15

can throw a chiller in there.

4:18

Super easy. I really like it.

4:20

Nice. Well, today

4:22

I wanted to do another Q and A session.

4:25

So I thought I might start by asking you

4:27

a bit about how home brewing a hobby as

4:29

a hobby

4:30

has evolved over your long career. And you've

4:32

been brewing quite a long time, if I recall.

4:35

Yeah, you know, the thing with

4:38

home brewing is

4:41

it's become a lot

4:43

more technical over time, which

4:46

I guess is to be expected. And, you

4:49

know, the ingredients we have

4:51

today, I remember when I started,

4:53

you know, it was, the

4:56

only information was books,

4:58

magazines, and then

5:00

there was a, you know,

5:02

bulletin board that you could, you know, dial

5:05

up on your modem and get into

5:07

the bulletin board and chat with people. And

5:10

I remember a lot of the advice back then

5:13

was,

5:14

you know, just really weird,

5:16

weird old school advice. And,

5:19

you know, now

5:21

today it is, people

5:23

are using, you know, just

5:27

they have access to

5:28

bio-engineered yeasts. They have,

5:32

you know, new,

5:33

new hop products that

5:37

were designed for the pros, but, you know,

5:39

are also available in your home brew shop.

5:42

They have, you know, all sorts of ingredients

5:44

that we never had before. Yeah,

5:47

that's kind of why I want to do an update

5:50

to brewing classic styles is because all

5:52

the ingredients have really changed. And,

5:55

you know, home brewers have

5:57

gotten so technical now that...

5:59

You know, a lot of them are more technical than

6:02

the

6:03

commercial craft brewers.

6:05

Commercial

6:05

craft brewers, they don't have time to study

6:07

every last little, um, you

6:10

know, uh, invention. Whereas people

6:12

that home brew are really doing a lot

6:14

of that.

6:16

Yeah. I've been surprised a lot of home brewers, uh, you

6:18

know, for example, spend more time on their water than the pros

6:20

do. Oh, absolutely.

6:23

Water hops, you know, it's mass

6:25

schedules. They want to control everything to, you know, the

6:28

nth degree.

6:29

Um, it's, it's surprising,

6:31

uh, how

6:33

detailed and technical, uh, home

6:36

brewing has become.

6:38

One of the things I noted, um, back

6:40

when you and I started, uh, it

6:42

was the early internet and one of the challenges

6:45

is, uh, the people that dominated the conversation

6:47

at that time, when we were developing

6:49

really a lot of the home brewing and even pro

6:51

brewing technology, uh,

6:53

we're scientists and engineers. So they kind of

6:55

dominated the whole discussion back then.

6:57

Yeah. They

7:00

still are today. Yeah. So that's,

7:03

so that's one of my things though. I don't know if you ever see

7:05

my designing beer presentation, but I often you

7:07

do a slide at the front where I talk about, you know, some

7:09

of the, uh,

7:10

because of beer brewing has become

7:12

so technical unit, the home brew level. Um,

7:15

it's sort of hidden some of the artistic elements,

7:17

you know?

7:18

Absolutely. I don't

7:20

know if you feel the same way, but, uh, yeah,

7:24

I think, you know, there, there's a need for the

7:26

technical. Um,

7:28

but you know, a lot of the fun, and

7:30

that is a lot of fun for a lot of

7:32

people that, you know, uh, be included,

7:35

but, uh, you know, sometimes it's

7:37

nice to see some, you

7:39

know, some artistry or some just, you

7:41

know, crazy thinking

7:43

type of.

7:46

I like, uh, I like some of the beers that

7:48

are built around a particular flavor, flavor,

7:50

you know, maybe an unusual flavor, you know,

7:52

or ingredient or something.

7:54

Um, anyway, so I thought I'd start today

7:56

with a few of the trends and craft brewing. and

8:00

one of the ones we're seeing at least in the last

8:02

couple years is a move towards Continental

8:04

style loggers

8:06

and sort of a resurgence of

8:08

things like Czech style Pilsners.

8:10

What

8:12

advice do you have for those looking to make maybe

8:14

the perfect Pilsner or

8:16

Continental logger at home?

8:18

Well,

8:20

I just

8:23

recently was

8:24

down at Disneyland for

8:27

May the 4th and stopped

8:30

in to see my good friend Rick

8:33

at stereo brewing.

8:35

The real close there, if you're ever down in the

8:37

Disneyland area you need to get a

8:39

stereo brewing and check them out. He's

8:42

a great brewer and every beer

8:46

on there was perfect,

8:48

just super well done. But

8:50

the one that

8:52

blew my mind was his Czech

8:54

style Pilsner

8:56

and it

8:59

tasted like

9:04

the best Czech Pilsners

9:07

of the world and it

9:10

was better than any Czech Pilsner

9:12

I've ever had other than

9:14

the classic historical breweries.

9:21

It was absolutely fantastic

9:24

and the way that he

9:26

made it was one, the

9:28

quality of ingredients. So he was using

9:30

a Vyramin floor

9:33

malted Bohemian Pilsner

9:35

malt

9:37

and the flavor of that malt was

9:39

fantastic.

9:40

When you're making these styles of beer,

9:43

the ingredients really shine

9:45

through and so you need to be choosing

9:48

the high quality ingredients.

9:50

Vyramin did just a brilliant

9:53

job on that malt.

9:54

It really tastes fantastic.

9:57

His

10:01

recipe is the hemean, you

10:03

know, the form vaulted, the

10:06

hemean pilsner malt from firemen, and

10:08

then some czech sauce hops,

10:10

and yeast water,

10:12

right? So very, very traditional recipe,

10:15

right? Yes, quality hops,

10:17

you know, great fermentation, and

10:20

you know, that's the trick. Yeah, I

10:23

was gonna say where the magic's done is really in the process,

10:25

trying to get all those flaws out, if you

10:27

will, because anything in

10:29

a pilsner's gonna show up, you

10:31

know, is a big problem. Especially

10:33

on a beer like that, and he just,

10:35

he did a masterful job of it. Again,

10:38

he's just a fantastic brewer, and

10:41

really knows the stuff, and just, I

10:43

wish that beer was available

10:46

all

10:50

across the US, or all across the world,

10:52

if you could easily get it.

10:55

It's that good,

10:57

really that good. That's

10:59

awesome. So I mean, are

11:01

there any things we can do, you know, at the homebrew

11:03

level to get something close to that, maybe?

11:06

Yeah, you know, source,

11:09

high quality ingredients. So

11:11

the proper malt, proper

11:15

hops,

11:16

use, you know, proper yeast,

11:19

I would suggest

11:23

using something, you know, that

11:26

is a check,

11:28

check log or yeast from any

11:30

of the major yeast producers,

11:33

and

11:34

watch your fermentation, start

11:37

your fermentation low,

11:39

and raise it up as you go. You will need temperature

11:41

control fermentation. Don't try

11:43

and do this with Kavike yeast.

11:46

It's just, you're just

11:48

gonna ruin the good ingredients

11:51

with

11:52

something that is not gonna be a lager.

11:54

You know, don't try

11:57

fermenting it. hot

12:00

with lager yeast and then cooling

12:02

it down, that doesn't really work either.

12:06

Just go with traditional methods.

12:09

If you're trying to make a

12:11

world classic, it

12:13

developed how it did

12:15

for a certain way and you're

12:17

going to want to stick with those techniques.

12:23

Well, another trend is towards low

12:26

alcohol and no alcohol beers in the

12:28

craft beer industry. In particular,

12:30

we're seeing some innovative work done with new yeasts

12:32

and techniques

12:34

that really avoid the traditional process where

12:37

you might brew a beer and then try and boil

12:39

the alcohol out of it, if you will.

12:40

So

12:43

what are your thoughts on some of the non-alcoholic

12:45

beer coming out and also how

12:47

it's made? Yeah, when I was at Heretic,

12:50

we looked at all the methods of

12:53

making non-alcoholic

12:56

or zero alcohol

12:58

or below 25 and

13:01

then low alcohol

13:03

beers. And it's

13:07

interesting because every

13:10

supplier looks at the problem

13:13

from their point of view, right?

13:17

So equipment manufacturers,

13:19

people make stills, they were making

13:23

vacuum stills to

13:25

vacuum off

13:28

the alcohol without heating

13:30

the beer up too much. Then

13:33

there were people who used essentially

13:35

reverse osmosis, a special membrane

13:37

filtration to filter the

13:40

alcohol out.

13:41

I thought that that was actually the best method.

13:43

You

13:44

end up with

13:46

beer without alcohol and then you end up with just

13:48

plain alcohol that you can use for other

13:50

stuff like seltzers.

13:53

You can actually bind

13:55

those membranes yourself.

13:58

I looked into that. They're not cheap.

13:59

But you put high enough pressure,

14:02

you could probably make it work

14:04

as a home burner. I'm sure there's enterprising home brewers who

14:07

want to do that.

14:08

And then the

14:11

malt suppliers, for example,

14:14

Muttons,

14:16

they sent me some tests

14:19

of

14:20

malt extract

14:22

that you essentially

14:24

mixed in with water and

14:26

it was a non-alcoholic beer already and

14:28

you hopped it. Or

14:30

you added a little

14:32

bit of what we would do was take

14:35

one of our higher alcohol beers because there's

14:38

more esters to it. And

14:40

we would take a double

14:42

IPA

14:43

and mix just enough

14:45

of that with the malt

14:48

extract

14:49

to bring it up to 0.5

14:51

ABV.

14:52

So

14:54

it was still considered non-alcoholic,

14:57

but you got some of the flavors of fermentation.

15:01

And that actually worked quite well

15:03

also. So that's

15:06

another method of making it, again,

15:08

based on the malt supplier end

15:11

of things. And now you also

15:13

see the yeast suppliers getting in on the game.

15:17

Malamond has a really good low

15:20

alcohol yeast

15:23

and it doesn't ferment maltose, maltotriose,

15:26

or any of the longer

15:28

chain sugars. It just ferments, I

15:31

think, glucose, maybe fructose. I don't

15:33

know. I would imagine it would do fructose too.

15:37

And so since that's a very low portion

15:40

of the

15:42

sugars in a mash,

15:45

you get really

15:47

high

15:49

mash temperature, you

15:51

get more complex sugars

15:53

and less simple sugars, and

15:56

then you ferment it with this and it's less

15:58

than 15%.

15:59

of the sugars in a typical

16:02

mash is fermentable

16:04

with this yeast. So you get a fairly

16:07

low alcohol beer and

16:10

you can get it below the 0.5 if you

16:12

are careful

16:15

about how high

16:18

you're going. You can also water

16:20

it back. So you can take,

16:24

you could brew an intensely flavorful

16:26

beer at

16:27

a higher alcohol.

16:29

You can use carbonated water to do this

16:31

with a robust porter and

16:35

just add water to it. I'd

16:37

pour myself a half or

16:39

three quarter glass of water and then top

16:41

it up with a robust porter

16:44

and you can use carbonated water

16:46

to do that. That

16:49

tastes good too. So a lot of different

16:51

methods for doing it. I would

16:53

say the best for a home brewer currently

16:56

is, the

16:58

quickest and simplest, just add some, keep

17:01

some ice cold

17:02

carbonated water on hand and

17:04

mix that with beer and I guess you lower

17:07

alcohol beer. The second

17:09

would be brew something

17:11

using the Lalamond low

17:14

alcohol yeast at LA1,

17:16

I think it's called LA for low alcohol.

17:20

I personally tried a couple

17:22

of the European yeast suppliers,

17:25

low alcohol beer. It was actually quite good. It wasn't bad

17:27

at all.

17:28

It was made using the low alcohol yeast you

17:30

mentioned.

17:31

Because it's fermented. One

17:33

of the things,

17:35

you can't just take a plain

17:37

malt extract and not have some fermentation

17:40

character in there.

17:41

It just seems kind of

17:43

flat and weird.

17:46

So

17:49

again, if you're using the malt extract, add

17:52

some beer to it and

17:55

it actually tastes pretty good. I

17:57

kind of enjoyed the results of the month's

17:59

test.

18:00

I thought that they were onto something there.

18:03

And then if you've got a lot of money

18:05

and space for it, you

18:07

could go with the

18:09

vacuum distillation or the membrane,

18:12

the osmosis

18:14

technique. Yeah, yeah. Well,

18:18

let's switch to one more. One of the most popular

18:21

styles, of course, is the hazy IPA. How

18:24

do you get the haze into the hazy IPA?

18:26

It's a classic. You know, that's

18:29

interesting. I worked on it for

18:31

about two years

18:33

to get

18:37

a truly permanent haze in

18:39

one of our beers. When

18:42

we started out, we just started following everybody

18:44

else and used everybody else's advice

18:47

on

18:48

what we heard from

18:51

various people on the internet, how to make

18:53

a hazy. And what we had was

18:55

a nice beer that was hazy,

18:58

but a lot of it would drop

19:00

out. And eventually, if you left

19:02

it long enough,

19:04

we would do haze tests

19:06

in the cold box. We'd have the cones

19:09

and checking for how different

19:11

tests

19:13

were coming clear.

19:15

But over the course of several months,

19:18

that beer would be almost perfectly

19:20

clear. Yeah.

19:21

And a bunch of sludge

19:24

in the bottom of the can. So that was unacceptable.

19:26

And so I started working on really

19:29

understanding where the haze

19:31

comes from, what makes it permanent.

19:33

So it's a combination of things. And

19:36

it's surprisingly the

19:38

common

19:40

problem, because one thing about

19:43

the hazy beers, if there's

19:45

a bunch of sludge in there, and

19:48

you can taste particles and there's,

19:51

you know, hot burn from ingesting

19:54

actual hot material,

19:56

you don't have a good beer. If you're drinking,

19:58

you know, glass.

19:59

of yeast that hasn't settled out,

20:02

you're not drinking a good beer. That's

20:03

a real, that's

20:07

garbage. That's why people hated hazy

20:10

IPAs. And some people still hate hazy

20:13

IPA because of there's

20:15

so many bad examples.

20:17

But what you want

20:19

is a permanent haze. You want

20:21

the yeast to have settled out. You

20:24

want, you know, all a hot material

20:26

to drop out as well. At

20:28

Heretic, we actually centrifuged

20:32

the beers, our hazy beers.

20:34

And they're quite hazy

20:37

even after that. But we would get

20:39

all the yeast out and all that other material

20:41

that you don't want to drink.

20:44

So what's the secret then? How are

20:46

you getting the haze in there? Right. So

20:50

the one thing is that we found out is most

20:52

people are

20:53

over doing it with wheat

20:56

and oats.

20:58

So and

21:01

you know, we were doing the same thing. It's like, well,

21:04

all right, it needs to be more, you know, add

21:06

more, add more of the haze causing things

21:08

because then

21:10

you'll get more haze, right?

21:12

Isn't that what everybody thinks? The

21:14

problem is wheat and oats, the

21:17

the the the glucanin

21:19

will

21:20

act as a

21:22

clarifier and will cause

21:25

the the haze to drop out

21:28

of the beer.

21:29

So you want to keep

21:32

yourself to about 20 percent

21:35

total. So that's

21:38

still, I mean, it's still a good percentage. It's still

21:40

a good percentage. But if you exceed that, you

21:43

are going to start having the glucanin

21:45

drop your

21:48

your

21:50

haze out. The

21:52

other thing I did was I switched.

21:55

So

21:56

they actually make some wheat

21:59

malts.

21:59

that are much higher in protein

22:02

and certain proteins contribute

22:04

to the permanent haze. What

22:06

is it, Hordine or something like that.

22:08

And

22:11

there's certain growers that

22:13

make real

22:17

high protein wheat. And the

22:19

idea is the higher the protein,

22:22

the

22:25

better the ratio between protein and

22:27

the glucons. So

22:30

let's say you have

22:32

X amount of glucon

22:34

and X amount of protein. Well, if you can

22:36

get the protein higher, then it's like

22:38

you're adding less glucon

22:40

and you can get

22:43

more of the haze forming proteins

22:47

without clarifying the beer. So that

22:49

is a grower

22:52

out or a grower. There's a grower

22:55

up in Oregon or Washington that

22:57

makes a malt that a lot of people

23:00

use. I think it's something

23:02

crazy like, well, it's like 15 or 16%. But

23:06

what I found instead,

23:10

much more readily available

23:12

and really close to

23:14

the same specs was spelt.

23:17

So spelt is essentially wheat.

23:20

So we started using spelt

23:24

in our beer. We

23:26

replaced

23:29

about half the wheat with spelt.

23:31

And that

23:34

made a big difference. And we lowered the

23:36

total amount of wheat and oats.

23:38

We used flaked oats and

23:41

spelt

23:41

and regular malted

23:44

wheat.

23:46

And then the

23:48

other thing was

23:50

yeast selection. The

23:53

yeast that I

23:55

really

23:56

loved for hazies is the

23:58

Imperial juice.

23:59

yeast. I think that that's a

24:02

great yeast. The thing

24:04

is to get it to ferment to,

24:07

because we made a lot of higher

24:09

ABB beers, we made

24:13

a fourth of Juicy, which I think

24:15

was 14% Juicy or

24:18

Hazy. And the

24:20

problem with a lot of

24:22

the Hazy Yeasts is that

24:25

they're based off of,

24:27

I think British strains, which are

24:30

typically lower attenuators.

24:34

And they tend

24:36

not to brew really high alcohol

24:39

beers in Britain. So... Right.

24:41

So the yeast is going to max out, right?

24:43

Yeah. What you need to do is

24:46

give it a lot of oxygen. So you give

24:48

it a lot of oxygen at the beginning. Then

24:51

people are trying to get 20 parts

24:54

per million in

24:56

dissolved oxygen in

24:59

their work to start.

25:01

I think you can give

25:03

it a dose at the beginning. You give it a dose

25:05

later on if

25:06

you want to

25:08

really

25:09

eight to 12 hours

25:12

later. Yeah. I've seen people use that with

25:14

meads and wines too. You hit it 12 hours

25:17

later with another dose. Yeah. Exactly.

25:21

And that yeast particularly needs a lot of oxygen.

25:23

And a lot of the British yeast, it goes back

25:25

to how they used to do

25:27

the double drop where they would

25:30

drop the beer through a centered pipe

25:33

to

25:34

entrain a lot more air into

25:37

the beer as

25:38

it dropped into the next fermenter,

25:41

which was Yorkshire Square

25:43

or something like that.

25:45

And the yeast really

25:47

need a lot of oxygen.

25:49

It also

25:52

helps with some of the ester

25:54

production later on.

25:56

And then are you doing things on the hop

25:58

side as well? Because obviously...

25:59

hops player as well in getting the haze.

26:02

So, yeah,

26:05

on hops, there's no boil additions.

26:07

You don't need them.

26:09

Your bittering is going

26:11

to come from actually from your dry hopping

26:13

mainly. But we would do a

26:15

whirlpool addition. We'd lower the temperature

26:17

of the whirlpool down to about

26:20

175 Fahrenheit. And then add

26:23

the hop addition there.

26:25

That addition is where you're going to add all

26:27

your linalool

26:30

and geraniol high

26:33

hops. Right. That's you want to add.

26:35

You try and get the bio transformations during

26:37

fermentation, right? Uh-huh. So you

26:39

need yeast that will do

26:41

bio transformation. You add

26:43

the little

26:45

little geraniol

26:48

concentrated hops. In your whirlpool,

26:51

extract that out. You leave the hop

26:53

batter behind. Because you don't want that

26:55

in your beer. You don't want to throw hops

26:58

in

26:59

during fermentation. We did

27:01

blind taste tests with

27:05

a lot of people. And

27:07

everyone always preferred the non-fermentation

27:10

hopped beer.

27:13

They all preferred the beer that

27:15

was dry hopped after fermentation.

27:20

Dry hopping during fermentation, it

27:22

adds an

27:26

unpleasant bitterness to the beer. Unpleasant

27:28

character from leaving the hop batter

27:30

in and stirring the hop batter around

27:33

for so long

27:34

that it becomes unpleasant.

27:37

So we stopped doing that.

27:39

And

27:41

returned to dry hopping after fermentation, which

27:44

also helps with harvesting your yeast. The

27:46

other thing we would do is we only

27:48

we would

27:50

throw all the dry hops in

27:53

and then pump the

27:55

beer around for about three hours. This was on

27:57

a 147. barrel,

28:01

US barrel fermenter, 120

28:03

barrel net.

28:04

You could pump the beer around for about

28:06

three hours, and that was

28:09

dry hopping. And once that's

28:11

done, we let it settle

28:13

and take the beer and move

28:15

it over centrifuge and it

28:18

was good to go. So don't dry

28:20

hop for long periods of time. That's

28:22

not good for your

28:24

hazies. You want kind

28:27

of a fruity soft character

28:29

to the hazies.

28:34

And then the other thing was

28:36

water. So water,

28:39

your sulfate to chloride

28:42

ratio,

28:43

you want a lot of chloride. I ended

28:45

up

28:47

adding kosher

28:50

salt to the

28:52

beer. So we'd go through quite a bit of salt.

28:55

It adds to the softness and

28:57

makes your water ratios closer

29:00

to what you're looking for. So I mean, that reduces

29:03

your sulfate to chloride ratio, making it a

29:05

little more mild, right?

29:07

Yeah, more chloride. Normally

29:11

with an IPA, you'd be going the other way probably, right?

29:13

Exactly. Yeah.

29:15

And with all those changes, you should get something

29:18

that remains hazy permanently.

29:20

So we, like I said, we

29:22

could centrifuge. And normally

29:25

you can centrifuge a beer quite

29:27

clear, but we could centrifuge

29:29

this thing to

29:31

where it's still quite hazy. You

29:34

removed all the yeast, you removed

29:37

all the hot matter. So it drinks

29:39

smooth and deliciously, and

29:43

it would stay hazy

29:44

permanently. I mean, after

29:47

a few years, I'm sure, you know,

29:49

a bit of dropout, but

29:51

you could go six months

29:53

a year and pour that beer and it would still

29:56

be hazy. Amazing. Cool. Thank

30:00

you. That was, I learned some new things there. I appreciate

30:02

it. Um, anyways,

30:04

uh, next question, you, you wrote the book brewing

30:06

classic styles and you brewed all the styles.

30:09

Basically. Uh, the question

30:11

was, uh, which styles were most challenging

30:13

to make at home?

30:15

Well at home, I think

30:18

the most challenging ones are the ones

30:20

that required a long term,

30:23

uh, storage, uh, for,

30:26

for, uh,

30:27

you know, development of flavor.

30:29

Yeah. Mainly the, uh,

30:32

you know, the barrel age sours. Um,

30:35

so the, the thing about those is time and

30:38

temperature, uh,

30:40

you know, the conditions, uh, you know, the amount

30:42

of oxygen that's getting permeating

30:45

through the wood or whatever vessel you're

30:47

using

30:49

make a difference in the final, uh, flavor

30:52

of the beer. So,

30:53

uh, it's

30:56

pretty critical. And if you're storing something

30:58

like this for, you know, three

31:00

or four years, you're,

31:04

you know, finding out whether it worked

31:06

out or not is can be, can be tricky.

31:09

Um, when I was at heretic, um,

31:12

you know, we had a barrel program there at one point,

31:14

I think we had about 500, uh, wine

31:16

barrels filled with, uh, various

31:19

sours

31:20

and, uh, you know, a sour base that

31:22

we worked with.

31:24

And you'd

31:26

be shocked, uh, you know,

31:29

same Baker of barrel from

31:31

the same winery, you

31:35

know, in Iraq, you know, next

31:37

to each other and, you

31:40

know, filled at the same time from the same,

31:42

from the same beer that we had brewed.

31:45

And one tastes

31:48

absolutely fantastic

31:51

and one tastes like garbage. Yeah.

31:53

And you know, the only way

31:56

we could put out really great product

31:58

was

31:59

we actually had a person

32:02

that

32:03

his job was to taste all the barrels

32:06

and make notes.

32:08

And he would come in and taste through as many

32:10

as he could, maybe, you know, the next day,

32:12

same thing. And

32:16

the thing was, you

32:19

know, because we had so many barrels,

32:21

we were able to just

32:24

drop, you know, if something

32:26

didn't taste good, we just dumped it. Well,

32:30

the other thing I've talked with Michael Tonsmeyer

32:32

about this quite a bit, but most of the programs

32:35

that people, you know, people that have a large

32:37

barrel-aged program

32:38

do a lot of blending. Yes. Well,

32:42

the thing about blending is, if something

32:45

doesn't taste good, blending

32:48

it in with beer that does taste good

32:50

just makes the stuff that

32:52

tastes good not taste good. Right.

32:55

It reduces the quality of, you know,

32:57

you have a barrel that's absolutely fantastic.

33:01

And, you know, you love it.

33:03

Well, why would you blend in

33:05

something that doesn't taste

33:07

nearly as good

33:09

just to avoid throwing

33:11

it away?

33:14

My method was always,

33:15

if it doesn't taste good, just throw it away.

33:17

And if you

33:20

stick with that,

33:22

then the blend that you're going to make is

33:24

always going to taste fantastic. If you're only

33:27

blending fantastic tasting

33:29

beers, you're only going to get fantastic tasting

33:31

out of it at the end.

33:32

So we would just throw it

33:34

away. There's no, you know,

33:38

you know, you can't

33:40

save, you know, garbage and

33:42

fix it in, garbage in, garbage out. So

33:45

we were very, very

33:48

strict on that. And that's why I had

33:50

so many barrels because I knew that, you

33:52

know, a percentage of them would work. And if

33:54

a barrel didn't work,

33:56

generally it meant that

33:58

it was, you know, know, if they

34:00

were the

34:03

barrels on the ends of the racks versus the barrels

34:06

in the middle of the stacks have different environmental

34:08

conditions and that makes a difference. But

34:12

you know, generally you get a couple barrels sitting

34:14

next to each other and

34:15

one doesn't taste right.

34:17

You take

34:19

you pull that barrel out of the program,

34:22

you know, and give it

34:23

away to,

34:26

you know, home brewers or

34:29

people making planners or one

34:31

guy took a bunch of our barrels and made

34:34

Adirondack chairs out of them. Oh,

34:36

nice. And he gave me a set of them

34:39

and a little table. It's really, really sweet. It was

34:41

really nice. Sounds awesome. Yeah.

34:44

Well,

34:44

cool. Well, related to this closely,

34:47

I guess, how important is judging

34:49

beer as a skill to develop as a brewer?

34:51

You know,

34:53

we've often heard that great beer judges make

34:55

great brewers, but what's your

34:57

experience with that? I don't think that's true at all.

34:59

No, there's great

35:01

beer judges out there, but they do not

35:04

make good beer.

35:07

There's, you know, but, you know,

35:09

there's great, you know, I don't

35:12

know, engineers out there who don't

35:14

paint very well. You know,

35:17

you see, you know, you see, you

35:19

see that in many walks of life.

35:22

But

35:22

yeah, I think if

35:25

you're a good brewer,

35:27

honing

35:27

your

35:30

judging skills will only

35:32

help you.

35:33

Right. Really is a fantastic

35:36

skill to have. And I think

35:38

it limits

35:41

your ability as a brewer if you

35:43

are not a good judge of beer. So

35:46

you have to you have to be critical

35:48

of your own beers. You have to, you know, really

35:52

be able to find

35:58

what's wrong with your beer and what's right with your beer. You

36:00

need to be honest with yourself.

36:03

Too many people, I'm sure you've experienced

36:05

this,

36:08

they run

36:10

up to you with their best beer ever.

36:12

And it's an obvious flaw

36:15

and they can't taste it. They

36:18

just, it's not anything. I've run into

36:20

it at the professional level. I go into a brewery and I

36:22

can taste an obvious flaw in the beer and I

36:24

almost feel like walking up to the brewer and

36:27

talking to him, but usually I don't.

36:29

Right, right. And

36:31

they don't taste it. And you pointed out there's

36:33

like, what? No, it's like,

36:36

so it's tough. That's

36:38

one of the beauties of competition is, they

36:41

don't know whose beer it is.

36:43

And so you get a little more honest feedback.

36:45

I think that's important. But

36:48

learning to judge

36:50

is really good. But again, I

36:52

think if you're a great judge, that

36:55

does not mean you're gonna be a great brewer.

36:59

If you're a great brewer that is a great judge, that's

37:01

a powerful comment. I think it's hard

37:04

to be a

37:05

great brewer without being a great judge,

37:07

without being able to taste these things.

37:10

Awesome.

37:11

Well, this question is very closely related

37:13

to our discussion at the beginning of the show, but we

37:16

spent a lot of time talking about technical aspects

37:18

of brewing.

37:20

But how much of beer brewing is hard?

37:25

Well, I think it can be a lot, but

37:30

you really,

37:32

you have to first master the

37:38

technical aspects of brewing, I think. Brewing

37:41

should be fun. And

37:44

if that is just slapping together

37:46

ingredients and not worrying about it,

37:48

yeah. If you like the result,

37:51

then that's perfect. You don't need to do

37:53

more. You just need to enjoy brewing.

37:56

Share the beer with your friends. Relax.

38:00

have fun,

38:01

drink a homebrew. You

38:05

don't need to master the technical.

38:08

You need some technical. But I

38:11

think if you really want to get the

38:13

most out of the artistic side of brewing,

38:15

you have to first really

38:17

be

38:18

a very solid with

38:20

all your technical aspects of

38:22

brewing. You need to be able to repeat your

38:25

process

38:26

and things like that. And then the

38:27

artistic

38:29

things that you come up with will have more

38:32

meaning, will turn out better. More

38:34

impacts, I guess. Yeah, if you're

38:37

just throwing out artistic

38:40

ideas,

38:41

they may be the greatest ideas

38:43

in the world, but they're going to fail if there's

38:46

not solid brewing underneath them. So

38:48

make sure you can. I

38:50

always encourage people to brew the

38:53

traditional styles, classic

38:57

styles,

38:58

from a known recipe

39:00

that

39:00

produces great results.

39:03

And

39:04

once you do that, and

39:06

you have success

39:08

with that, then is when you start

39:11

coloring outside the box. That's

39:13

when you start

39:15

bringing

39:17

your own flair to things.

39:20

I'd love to encourage people to get

39:23

used to or get familiar with the flavors too

39:25

as well. Like

39:27

the ingredient flavors, a lot of people don't know

39:29

the difference between one hop and the other, for

39:31

example.

39:32

Right. I think one

39:35

of the best ways to

39:37

become more familiar with the flavors

39:40

is to do the smash

39:43

beers, single hop.

39:46

Single hop, single malt, right? Yeah.

39:50

Single malt, yeah. Smash

39:54

beers, I call them. And

39:57

you do that.

39:59

let's say,

40:02

you know, you get used to that.

40:04

Then you can, you know, add, you know,

40:07

something like a crystal 40 and see

40:09

how that beer has changed.

40:11

And once you get used to those flavors,

40:14

um, also, you know, tasted chew

40:16

some of the ingredients, um,

40:19

you know, sniff your hops,

40:21

sniff your mold, your, your, your specialty

40:24

grains, taste some of the grains.

40:26

Um, well, they have this, uh, you've probably

40:28

seen it. And I'm sure that the new ASBC method

40:30

for doing sensory analysis on malt, where you

40:32

make a little tea out of the mall, it's actually very effective

40:35

for getting an idea

40:36

of what the malt flavor might be. Absolutely.

40:39

That's a great method as well. Great thing for

40:41

a club to do or something like that. Yeah.

40:44

And you can do that. And if you've

40:46

done a smash beer to

40:49

compare it to, um,

40:51

then, um, you

40:53

know, once, once you've got that

40:56

and you go, okay, this is what this, this especially

40:58

malt tastes like,

40:59

uh, in a beer, this

41:01

is what it tastes like in a tea. And

41:03

then when you do the other teas, let's say, you know,

41:05

crystal 10, crystal 80 and crystal one 20,

41:09

go, okay. Now I'm

41:11

getting more of a sense of how that'll play out in a

41:13

beer.

41:16

Um, have you experimented and built,

41:18

uh, beers around a maybe unusual

41:21

ingredient flavor? I know there's a lot of, uh, interesting

41:23

stuff coming out of South America, for example.

41:26

Yeah. Um, I,

41:29

not a lot. I mean, single ingredient,

41:31

uh, usually, um,

41:32

you know, multiple ingredients,

41:35

you know, uh,

41:37

but, uh, I, I, I did

41:40

a really nice, uh, bacha

41:42

bacha tea IPA. Um,

41:45

that was just, you know, bacha tea and,

41:48

you know, you know, IPA. I

41:50

thought that that was a lot of fun. I

41:52

really enjoyed that. Um,

41:53

yeah. You know, the color,

41:56

you know,

41:56

the haze, uh, and, and just

41:58

that tea character is great.

41:59

And then used a

42:03

lot of woods, some

42:07

of the woods that are available now

42:10

from South America have

42:15

some really interesting spicy characters

42:18

to them. Other than that, single

42:20

ingredient, no, generally

42:22

multiple ingredients. And the reason

42:25

being to add a layer of

42:28

complexity to

42:30

those beers. Have you built a

42:32

lot of beers around spices or fruits?

42:35

Yeah, a fair amount.

42:38

Especially in our sour program,

42:40

we did a lot of different fruits,

42:42

we

42:42

did some spices. It's

42:45

really fun to work with spices

42:48

and fruits. It's

42:51

a bit more like cooking. And

42:54

it really makes

42:57

dramatic change and

42:59

you'd be surprised playing around with some

43:01

of your favorite food flavors

43:04

and how they can marry up in beers. That's a

43:07

really fun way going about it.

43:10

Well, I wanna talk about high alcohol beers

43:13

now. They can be a real challenge because

43:15

you get, first of all, you get a lot of times low efficiency

43:17

out of the mash, but then you also have,

43:19

as you mentioned earlier, long age times

43:21

with a lot of them.

43:23

Do you have advice for brewers looking

43:25

to jump into the higher gravity

43:27

styles? And I know this is something you've

43:29

done a lot commercially.

43:31

Yeah, when it comes to certain beers, you

43:37

make barley wines or things like that, aging

43:40

time is nice. You can see how the beer

43:43

changes over time. Old

43:46

ale,

43:47

I just

43:49

recently brewed Gail's prize old ale

43:53

in England.

43:55

And that's a beer

43:57

that can age. a

44:00

long time it really changes in complexity

44:03

as time goes on. The

44:07

thing

44:09

though about Hayek and Paul Beers

44:11

is

44:12

they shouldn't need long

44:14

aging if it's not part of the style.

44:17

For example, at

44:18

Heretic, we

44:20

made the 18% IPA called whale

44:24

juice. And we

44:26

every year made an evil three

44:28

that beer with Mitch Steele

44:31

and Tasty

44:32

McDowell and myself

44:35

that was 11.5%.

44:38

And those ferment

44:40

and are ready just

44:42

like any other beer of beer that's 4%.

44:46

And that's

44:48

based off of good fermentation

44:50

practices.

44:52

Healthy yeast,

44:55

proper temperature control and

44:57

a word that can

45:01

ferment to those high degrees.

45:03

So when you're making something

45:05

like an 18% IPA, what you're

45:08

going to do is build

45:11

a high gravity

45:15

IPA to start with. When

45:19

we did our evil three, it was

45:21

all malt. It was like

45:24

we added sugar,

45:25

dextrose and all. And we add a little bit

45:27

of dextrose.

45:28

But

45:32

you do it all malt beer if

45:34

you're bringing something real high gravity.

45:38

Ferment that out using your

45:41

yeast

45:42

and a good pitch of yeast and nice

45:45

healthy ferment.

45:48

Get that thing to attenuate, eat all

45:50

the maltose maltotriose

45:52

that's in there and then start

45:54

dosing with dextrose

45:57

and the dextrose will ferment out easily.

46:00

Be careful, you don't want to

46:02

dump in a bunch

46:05

of dextrose that won't ferment, so you

46:07

dose it each day

46:09

with as much as the yeast can take that day.

46:12

You can add some nutrients,

46:14

you can even add oxygen, and

46:18

slowly bring the ABV

46:20

up. Like that

46:23

similar technique that dogfish

46:25

use

46:26

on their 120, I think it is, and

46:29

I think Sam Adams

46:31

used on their Utopia

46:34

as well. You

46:37

can bring a beer up to about 25% doing that. Wow,

46:41

so you're basically just adding sugar

46:43

at the end to try and drive the ABV up, huh?

46:45

Yes, use dextrose, don't

46:48

use cane sugar or beet sugar or anything

46:50

like that.

46:52

The flavor of those when they ferment is

46:54

not as pleasant as dextrose. Dextrose

46:57

is much better sugar to use for beer brewing.

47:01

And

47:04

yeah, you can chase the ABV up.

47:07

So that gets around a lot of the problems

47:09

with really big mashes, for

47:12

example, right?

47:12

Right. You

47:16

still want to do as big a mash as you can. You

47:19

want to get all your malt flavors

47:22

and all that in there as high

47:24

as possible, but

47:25

you want that to fully attenuate.

47:29

And then

47:30

start adding your sugars. If you do it all

47:32

at once, the yeast

47:34

will consume the simple

47:36

sugars

47:37

and then

47:39

really not consume as much

47:42

of the maltose. And

47:44

you end up with a very under

47:47

attenuated

47:48

character to the beer.

47:51

The other issue is, as you're doing this,

47:53

if you

47:56

add too much of the dextrose,

47:59

you have to kind of... to read the yeast and see

48:01

where it's slowing down and

48:04

when it's getting tired. And if

48:06

you can add another dose of dextrose, I've

48:08

tasted some other commercial

48:10

examples

48:11

where the brewers just kept

48:14

going and the thing ends up sickly

48:16

sweet.

48:17

So you have to be careful and stop

48:20

and you wanna leave as dry a character as possible

48:23

so the beer tastes like IPA

48:26

or something like that. And of course that has a lot

48:28

to do with the alcohol tolerance for the yeast you're starting

48:30

with, right?

48:31

Yeah, we did

48:34

whale juice with OO1,

48:37

the Y-Labs, I think they list the

48:39

alcohol tolerance on that as like 10%

48:41

or something, but

48:43

almost every yeast

48:46

around will do at least 15%.

48:50

Most of them can be pushed to 18%, fairly easy.

48:54

You've just gotta give them the right conditions.

48:57

So OO1 to 18%.

49:00

Wow. I think Chris

49:02

White was maybe surprised about that one too. Yeah.

49:06

Well, you're feeding it sugar obviously, so that's different.

49:09

Right. But you know, yeast

49:11

do, different yeasts do have different alcohol

49:13

tolerances, but and you could

49:16

use a different yeast if you really wanna push it up. There's

49:19

some yeast that'll do, like I said, 25%. We

49:22

like the character of the OO1 yeast, so

49:25

stuck with that.

49:27

So home brewing's been in

49:29

decline for about 10 years

49:32

now in terms of total numbers. Where

49:34

do you see home brewing go in the future? Is it gonna increase?

49:37

Is it gonna decline further? I don't know.

49:40

I don't know.

49:44

It seems like maybe a lot

49:46

of the home brewers have gone

49:49

over to professional brewing because a number

49:52

of professional brewing says has

49:54

really increased. I don't think that explains

49:57

all of the missing home brewers, but

49:59

I think it's...

49:59

goes back to what we were talking about earlier is

50:02

how technical home brewing has become. And

50:05

I think the way that home brewing

50:07

really took off and became

50:10

such

50:10

a trend was the work of

50:14

Charlie Papazian, where he was telling

50:16

people to relax and it's fun and

50:18

just have a home brew. And

50:20

he was right, and that's what really gets

50:22

people in. When people

50:25

are faced with

50:26

buying masses of stainless

50:28

steel and learning calculations

50:32

and dealing with water adjustments

50:34

and all this stuff, it kind of

50:37

makes the

50:38

barrier to entry really

50:40

high. And I think that that's the

50:43

problem we have now, is too many people are

50:45

talking about how technical

50:47

home brewing is. But it could be

50:49

simple and easy. With

50:50

the

50:54

Bruzilla that Chris Graham gave

50:56

me from Warbeard,

50:59

the first beer

51:01

I did on it, I didn't bother really,

51:03

I just said, yeah, like

51:06

eight pounds of base

51:07

malt, a pound of crystal and

51:11

a dash of roast and that was

51:14

it. I didn't check gravity, I didn't

51:16

do anything. I kind of

51:19

paid attention to the times, I just took it really

51:21

easy and I loved it. And it was so much

51:23

fun and so simple.

51:26

And that's, I think if other people

51:28

saw that, they'd go, oh, I

51:30

can just buy this one piece of equipment and that's

51:32

pretty much all I need. It's like, yep, that's all

51:34

you need.

51:35

And I think we'd get a lot more people

51:38

into home brewing. And whoever

51:40

those would love it, really want to take it technical,

51:42

which is great.

51:43

But we need to make sure that we're

51:46

furthering the simplicity of

51:48

home brewing, the joy of home brewing.

51:53

Some malt extract

51:55

on the stove with some friends

51:58

while you have pizza.

52:00

That is a fun

52:02

time. And if we

52:05

remember

52:06

those roots of home brewing, I think home brewing

52:08

could grow again and it will. But

52:11

if we all just keep going down the road

52:13

of

52:14

it being super technical.

52:16

And I'm

52:18

a big part to blame for that too. But

52:23

I like to remind everybody that

52:26

home brewing is actually super easy and super

52:28

simple.

52:29

It's easier than baking

52:31

a cake in some instances. So let's

52:34

do that and

52:36

home brewing will continue to thrive.

52:39

And then I guess just the last question I had was,

52:41

how do you feel about professional brewing? It's

52:44

obviously, I think we topped over 9,000 not

52:46

too long ago.

52:48

Craft breweries, are they going

52:51

to peak at some point? I mean, is this thing just going

52:53

to continue to grow forever?

52:58

I don't know. I mean, there is a

53:00

chance that we end up with 20,000

53:02

or 30,000 breweries in

53:03

the US. And

53:06

they'll all be really small places

53:09

that

53:10

in a way are too small

53:13

and will struggle every

53:15

day to make

53:18

a business of it. Something

53:20

will settle out one way or another. I think

53:23

the days of

53:24

bigger regional breweries is

53:26

kind of done.

53:31

Yeah, and we'll see.

53:34

One of the things that kind of concerns

53:36

me is.

53:39

And I think it was more when breweries were

53:41

growing really fast and there was

53:43

a lot of expansion in craft brewing. We saw

53:45

a lot of people entering

53:48

in and and even some people have been around

53:51

a long time.

53:52

Not the

53:56

craft beer and home brewing.

53:59

and commercial brewing

54:01

was a very communal thing,

54:04

a very sharing

54:07

and kind industry

54:09

where everybody helped everybody. And

54:11

if you didn't help everybody, something

54:14

was wrong with you. And it was you, you,

54:18

when people would come to

54:21

heretic, they needed cans, we'd give them cans. They

54:23

need a mall, we'd give them a mall. And

54:25

sometimes we'd go back to those people and say, hey, can

54:27

you help us out where we're

54:29

short a sack of, this or

54:31

that.

54:33

And everybody helped and everybody shared information.

54:36

Well, when the

54:38

growth was really upon us,

54:41

were a lot of people getting in and they were not

54:43

part of that group. They wouldn't share, they

54:45

didn't. It became

54:48

more contentious and unpleasant.

54:52

Then the pandemic hit and

54:55

things kind of crashed and then people

54:57

became insular. And then after

54:59

that has passed,

55:04

it's a really weird market and everybody's

55:06

suffering.

55:07

But you see some of the

55:10

people kind of getting back together again and

55:12

helping each other out.

55:14

And I wanna see that continue. I

55:16

think

55:17

without that, it's not craft

55:19

beer, it doesn't. And

55:21

as far as I'm concerned, the whole industry can go ahead

55:23

and die. That's the way

55:25

it's gonna be.

55:29

We all need to help each other. Rising

55:32

tide lifts all boats. We

55:34

need to work together to

55:38

help home brewers. Professional brewers should be helping

55:40

home brewers, not fighting with them or

55:43

arguing that they're

55:44

somehow unpleasant.

55:46

Home brewers should be helping craft

55:48

brewers and help promoting them.

55:50

We all should be working together

55:52

and we'll be stronger if we do.

55:54

And there will be more

55:57

opportunities for everyone, there'll be better beer

55:59

for everyone.

55:59

There'll be better ingredients and

56:02

better, you know,

56:03

inventions in,

56:06

you know, home brewing equipment,

56:08

professional brewing equipment, ingredients.

56:11

You know, we'll continue to see this thing

56:14

grow and improve,

56:15

but not if we don't work together.

56:20

Well, Jamil, I really appreciate you being

56:22

on the show today. Thanks so much for taking

56:24

time out of your busy day to be

56:26

here.

56:27

I love chatting with you, Brad. It's

56:30

always a pleasure. My guest today was Jamil

56:33

Zaynicheff.

56:34

He's author of Brewing Classic Styles and

56:36

the Practical Guide to Fermentation, and of course,

56:38

a professional brewer and podcaster

56:40

as well.

56:41

Thank you again, Jamil.

56:43

Take care, brother. A

56:47

big thank you to Jamil Zaynicheff for joining

56:49

me this week.

56:50

Thanks also to Crap Beer and Brewing Magazine.

56:52

They offer access to videos, brewing

56:54

courses, exclusive articles, and the amazing

56:57

Crap Beer and Brewing Magazine.

56:59

Go to BeerAndBrewing.com to get your

57:01

subscription today.

57:03

And also, Beersmith Web, the online version

57:05

of Beersmith Brewing Software.

57:07

Beersmith for the web lets you design great beer

57:09

recipes from any browser, including your tablet

57:12

or your phone.

57:13

Edit recipes on the go with access to tens

57:15

of thousands of recipes,

57:17

as well as a full suite of recipe building tools

57:20

that our desktop version has.

57:22

Try Beersmith Web today by

57:24

creating a free account at BeersmithRecipes.com.

57:27

Again, that's BeersmithRecipes.com.

57:31

And finally, a reminder to smash the like and

57:33

subscribe buttons on YouTube, iTunes,

57:35

Spotify, or whatever platform you're listening to.

57:38

It helps us in many ways when you click on that

57:40

button.

57:41

I'd like to thank you for listening, and I hope you

57:43

have a great

57:45

brewing week!

From The Podcast

BeerSmith Home and Beer Brewing Podcast

The BeerSmith Home Brewing Show is a beer brewing podcast focused on how to brew beer, homebrewing techniques, and beer stories from top US and international brewers. In each episode we bring you an interview with guests assembled from around the world to talk about beer, craft beer and homebrew. The BeerSmith podcast is hosted by Dr Brad Smith, the author of BeerSmith homebrewing software, the book Home Brewing with BeerSmith, and the BeerSmith blog which attracts over 200,000 readers monthly. Website: http://BeerSmith.com/blogJoin Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

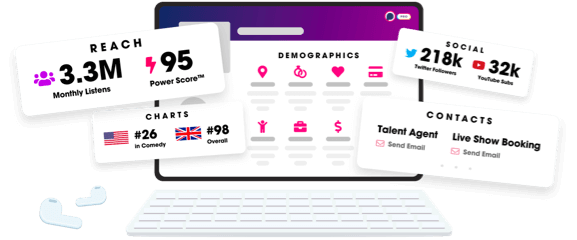

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us