Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:00

Rick Gehring joins me this week to discuss starting

0:02

a craft brewery on a shoestring. This

0:04

is beer smith podcast number 282

0:16

This is the beer smith home brewing

0:18

show We're brewing great beer

0:20

as our passion if you want to take your

0:22

brewing to the next level visit beersmith.com

0:25

Where you can download a trial version of our beer

0:28

smith software Subscribe to the newsletter

0:30

and get dozens of free articles on home

0:32

brewing And now your host and the

0:35

author of home brewing with beer smith brad

0:37

smith This

0:38

is beer smith podcast number 282

0:41

and it's early june 2023

0:43

Rick gehring joins me this week to discuss starting

0:45

a craft brewery on a shoestring

0:48

Thank you to this week's sponsors craft beer and

0:50

brewing magazine

0:51

Every issue of craft beer and brewing magazine

0:53

is packed with articles for home brewers and beer lovers

0:56

They offer access to videos brewing

0:58

courses exclusive articles and

1:00

the amazing craft beer and brewing magazine

1:02

Go to beerandbrewing.com to get your subscription

1:05

today And beersmith

1:07

web the online version of beer smith brewing software

1:10

Beersmith for the web lets you design great beer recipes

1:13

from any browser

1:14

including your tablet or phone

1:16

Edit recipes on the go with access to tens

1:18

of thousands of recipes

1:19

as well as a full suite of recipe building tools

1:22

Try beersmith web today by creating a

1:25

free account

1:25

at beersmithrecipes.com

1:29

And finally a reminder to smash the like and subscribe

1:31

button on youtube itunes spotify

1:34

or whatever platform you're listening on

1:36

It really helps us to add new listeners

1:39

And now let's jump into this week's

1:41

episode Today

1:43

in the show I welcome rick gehring rick is

1:45

head brewer at walnut river brewing west of wichita, kansas And

1:47

today rick's going

1:49

to share the unusual path. He took to building his brewery

1:52

Uh, rick, it's great to have you on the show

1:54

first time guest. How are you doing? Doing well,

1:56

I appreciate

1:57

having me on

2:00

How are things out there

2:03

near Wichita, I guess? You're 30 miles west,

2:05

I think you said? We're actually east of

2:07

Wichita, but yeah, just about 30 miles. Yeah,

2:09

no, not a problem. Yeah, we

2:11

are actually pretty busy. We

2:13

are the second largest craft

2:16

brewery in Kansas. Well, I guess we

2:18

switched back and forth to a second and third. We have one of our

2:20

rivals we fanned her back and

2:23

forth with, but yeah,

2:25

we are definitely busy this time of year.

2:27

That's fantastic. I think you mentioned

2:29

you started it up professionally about 10 years

2:32

ago, right?

2:33

Yeah, sure did. We opened our doors

2:36

in July of 2013.

2:39

That's awesome. And well,

2:41

can you tell us a little about your background and how you got started

2:43

brewing beer? I assume you probably did some

2:45

work at the homebrew level at some point?

2:48

Oh, absolutely.

2:50

I actually started back in

2:53

early nineties as a homebrewer. I

2:56

was in the IT field, kind of

2:58

bored with my career and

3:00

it was just kind of a fun hobby to get into. Of course,

3:03

I mean, beer is great anyway, but

3:06

I started there, did a couple

3:08

of homebrew kits, moved on to all

3:10

brain brewing pretty quickly.

3:14

Then really about

3:16

probably 25 years worth

3:18

of home brewing under

3:21

my belt. And along

3:24

the way, my wife was like,

3:25

you know, you seem to love this so much. You really don't

3:28

like your IT stuff anymore. So why

3:30

don't you look into opening a brewery?

3:33

Yeah, I was gonna ask, when

3:35

and how did you decide to do that? I mean, I

3:37

assume you were doing some other work.

3:40

You said IT?

3:41

Yes, yeah. I was like corporate

3:43

IT, say for just about 20 years. And

3:47

yeah, there's only so many times

3:49

you can fix a network or

3:51

reset a password before you get really bored.

3:54

Well, you took some

3:56

risks when you switched over.

3:59

from what I understand, right?

4:02

You decided to go all

4:04

in when you quit your

4:06

job.

4:07

Yeah, sure did.

4:11

With my wife's encouragement, of course, she's

4:14

the first person to keep happy.

4:17

We decided to take the plunge,

4:20

looked high and low for a

4:22

good place to do it. Of course, I'm

4:24

originally from Wichita,

4:26

so we looked there first.

4:28

But the issue was that the

4:31

prices of buildings and land were

4:33

really high. Water

4:35

quality in Wichita is really not that

4:37

great for brewing, you have to do a lot of fancy

4:39

stuff to it. So we

4:41

were looking in areas that

4:44

were close to El Dorado

4:46

and found that the

4:48

water quality up here was tremendous

4:51

and the price of real estate

4:53

was almost nothing really. And the

4:55

city was hungry for a new business. So we

4:59

bought an old building that the roof

5:02

was about ready to collapse on. And

5:05

to do that, we ended up selling our house so we

5:07

could divert

5:09

our mortgage payment we use on the house

5:11

into

5:12

fixing the building. Wow,

5:13

that's amazing. And from

5:16

what I understand, you actually lived in the building too,

5:18

right?

5:19

Yeah, we sure did. There was

5:21

a small apartment on the first floor of the building

5:24

and we decided to expand

5:26

it a little bit and move in.

5:29

So we lived in that, I

5:31

think we ended up with about an 800 square foot apartment.

5:33

Wow. And yeah,

5:36

it was myself, my wife, and

5:38

our two toddlers that we had at the

5:40

time. Oh my goodness.

5:43

Sounds challenging. And then

5:46

it took you a couple of years, I think, right? To get

5:48

the building fixed up to the point where you could actually

5:50

start a brewery.

5:52

Yeah, I wanna say it took

5:55

me right about five years

5:57

worth of say, diverting my mortgage payment into

5:59

it. to get it all fixed up

6:02

at about a two and a half year mark. And

6:04

my wife had enough of the small apartment. So

6:07

we had to buy a house under

6:10

her request. Okay. Well,

6:12

that's good.

6:13

Yeah, yeah. But

6:16

you were running a shop out of the building

6:18

too. I think she was, right?

6:20

Yeah. So we have our

6:22

buildings about 6,000 square feet or so,

6:25

but

6:27

with all that empty space, once we got everything

6:29

fixed up, my wife's kind of like, you know, we could

6:32

use that space and my mom and

6:35

I could make a flea market. They

6:37

just had a good time doing that on the weekends

6:39

that helped bring in a little

6:41

bit extra money.

6:43

And yeah, so they eventually

6:45

took over pretty much all the building. We

6:48

had an old alleyway between us

6:50

and the next building over

6:52

that was turned into the brewery at

6:54

the end.

6:56

And this all happened about 10 years ago and

6:58

you were, let's say at some point you started

7:00

actually getting serious about

7:02

buying the equipment and

7:05

putting the brewery up.

7:07

And from what I understand, you did it with a very small pile

7:09

of cash, right?

7:10

Yeah, very small.

7:12

Say all my money really went into the building. So

7:15

whenever I finally found a couple of

7:18

business partners to work with,

7:20

we pulled what cash we had, which

7:22

turned out to be about $50,000. And

7:26

the only thing we bought new

7:28

with that was the brew system itself.

7:30

And that was a two barrel system

7:34

that was about 35,000, I

7:36

think of that 50.

7:37

So we had $15,000 to build the rest of the brewery with.

7:41

That's amazing. And so you started

7:44

with a two barrel brew system. How

7:46

much other equipment, I mean, how many fermenters and so on

7:48

did you start with?

7:50

We started with two of the

7:52

two barrel fermenters that came with.

7:53

We

7:56

took up the plunge with that and

7:58

actually, I think within the first.

7:59

month of being open we started supplying

8:02

a local bar with with kegs and

8:05

soon discovered that the two barrel fermenters

8:07

were not big enough. So

8:09

with just a couple weeks after that we

8:12

ended up buying actually our first

8:14

bank loan that

8:15

we did bought a seven

8:17

barrel fermenter so we could triple batch into that

8:20

one. Wow and doing triple

8:22

batches has got to be a challenge right in one day

8:24

it's a long brew day.

8:25

It is a long brew day. We

8:27

got pretty good at it like I was able to do three batches

8:31

in about 11 hours

8:32

but at that time we

8:34

were I was still working full-time believe

8:36

or not to try to cover the bills. So you

8:39

worked full-time the whole time you

8:41

were

8:42

renovating I assume too right?

8:44

Yes absolutely. Yeah

8:46

and then when did you finally quit your

8:48

job? Wow let's

8:50

see it would have been probably about

8:53

three years into the brewery. Wow.

8:56

Yeah a lot of long weeks. So

8:59

what were you brewing on the weekend then? Yep

9:01

yep I come in on Saturday and brew three

9:04

batches on Sundays it

9:06

was usually kegging and transferring

9:09

and throughout the week it was just babysitting.

9:12

So initially were you running primarily

9:14

as a brew pub? Were you did you have basically

9:17

a tap room or something?

9:19

Well Kansas is a little weird on

9:21

their alcohol laws. Okay. And

9:24

as a microbrewery

9:27

here in Kansas we just got this law changed

9:29

actually just this year but

9:33

at least where we're located at you had to

9:35

sell at least 30% of

9:37

your everything had to be in food

9:40

if you wanted to be able to sell a pint of

9:42

beer across the bar. Okay.

9:44

But strangely we could give the beer away

9:47

so we could sit there and hand

9:49

out tasters

9:50

and then we could sell for hours a beer to

9:52

go. That was

9:53

how we did our first two and a half years essentially.

9:56

Interesting so you didn't have a

9:59

restaurant I guess.

9:59

So you just had, you literally,

10:02

you literally gave the beer away at the tap room

10:04

and then, uh, and then sold growlers to go.

10:06

Yep. That was the way we worked for the world

10:09

business model.

10:10

Yeah.

10:13

It wasn't what I had really expected

10:15

or desired, but it was the way it worked for the,

10:17

for the beginning. So that was, uh, you did that

10:19

for three years and then eventually did you open up and,

10:22

uh, and, um,

10:23

uh, create a restaurant, I guess, or what?

10:26

Oh, we did. I did a couple of different things.

10:28

So our demand grew enough where

10:31

we decided to go ahead and take out

10:33

an SBA loan

10:34

and we upgraded from a two barrel

10:36

system to a 30 barrel. Oh, wow.

10:39

Yeah. It was a, it was a huge jump,

10:42

but at that time we also added in a canning

10:44

line. Um,

10:46

we bought, I think at the beginning we started with,

10:49

uh, five 30 barrel fermenters,

10:52

um, with statewide

10:54

with our distribution.

10:56

Um, but at

10:58

that time we also opened up a tap room

11:01

in the brewery and

11:02

then

11:03

in 2018, we

11:06

also opened up a restaurant in Wichita

11:08

as well. That was a

11:11

big adventure for sure. Nice. Uh,

11:13

so yeah, so quite a, quite a bit of change in

11:15

a short number of years. I do want to go back

11:17

to the beginning though, because I was kind of interested. Um,

11:19

so obviously you spent most of your initial

11:22

cash on brewing equipment and, uh,

11:24

and keeping the building from falling down.

11:27

But what, what about the hundreds of

11:29

other things needed to get it up and running? I mean, how did

11:31

you get through all the, you know, usually,

11:33

uh, most of the people I talked to say that

11:36

they need 50 to a hundred percent over their budget

11:38

just to get up and running, uh,

11:41

because of all the things that come up with, you know,

11:43

code and, and, and fire

11:46

and, and all these other regulations that

11:48

put things in place. Oh,

11:50

you're not lying there.

11:53

Yeah. It was a lot of negotiation.

11:56

Luckily, at least with the city on the code

11:58

side, they were very forgiving.

11:59

They were very hungry for new businesses.

12:02

They gave us a lot of tax breaks. We

12:05

had

12:06

some grants available to us as well.

12:08

We were in their downtown revitalization

12:11

area. So they were, yeah.

12:13

So we got a little bit of grant

12:15

money as well. But

12:18

still, there are always cost overruns. You

12:20

just don't expect things.

12:23

You know, like we discovered, the sewer

12:25

line in the building was collapsed. So that had to be dug

12:28

up by hand. And stuff

12:30

like that. But you know,

12:31

we were gluttons for punishment. So on

12:33

a Sunday, we got a concrete

12:36

cutter and

12:37

did the work ourselves.

12:38

Amazing.

12:40

And the other interesting thing about your story,

12:42

I think, was that you told me you built

12:44

a lot of equipment from scratch yourself, which

12:47

is kind of interesting.

12:48

Can you give us a few examples of that?

12:51

Oh, absolutely. One

12:53

of the callbacks to being a home brewer is

12:55

you always want to be tinkering with stuff. At least

12:58

I always really enjoyed that aspect, trying

13:00

to

13:01

eke out efficiencies where you can

13:03

and try to get different techniques and equipment.

13:06

So in

13:07

my heart, it was always just joy of building

13:09

things.

13:11

So we did the same thing at the brewery. It

13:13

was very evident. So for

13:16

instance, the glycol chiller

13:18

reuse to cool down the fermenters was

13:20

built out of a Coleman

13:22

cooler and an air conditioning unit.

13:24

And yeah,

13:27

strangely enough, one of my friends, he's an engineer

13:30

and his hobby is designing cooling systems.

13:35

It was a little weird, but it worked out

13:37

in our favor. So he was able to design everything

13:39

from the heat loads and put it, you know, and

13:41

we built it and it worked great. He designed

13:43

this glycol chiller off

13:46

of an air conditioner that kept, I guess, your

13:48

first three fermenters going? Yep,

13:50

actually, we still have it. It works great. By

13:54

the time we retired it,

13:56

it was running two

13:58

seven barrel fermenters.

13:59

the three, two barrels and it was doing

14:02

great. No kidding. That's amazing.

14:04

And, um, what, give, give us some other

14:06

examples. I know you took a lot of other, uh,

14:09

uh,

14:09

shortcuts to cut costs.

14:11

Definitely. Um,

14:13

when we started, um,

14:15

putting our beer into cakes for bars, of course we

14:17

had to have a way of cleaning them.

14:19

And one of my, uh, never

14:22

earning projects seems to be designing

14:24

a building cake cleaners.

14:26

So my very first one was just a manifold

14:28

of pipes on the wall that did everything manually

14:30

and, you know, a single cake would take

14:32

me 25 minutes to clean.

14:36

But, um, when you're

14:38

at our level now and we're doing

14:40

several hundred cakes, you know, a week and

14:42

it just

14:43

doesn't work. So

14:46

we looked at commercial cake cleaners and

14:48

the ones that we really wanted, you

14:50

know, started at around $15,000 and it was like, you know,

14:54

we could do better. So, um, I

14:58

did a little bit of a

15:00

bookwork on it.

15:01

Actually went to school to do auto cats.

15:04

Well I could actually lay out piping on, on,

15:06

on a design. Um,

15:09

I learned how to weld stainless to be able

15:11

to build a frame for it. Oh, well. Uh, then,

15:14

um,

15:15

my education is actually in computer

15:17

engineering. I never really used it in my profession,

15:20

but it came in handy here

15:22

where I was able to design the control system,

15:24

do the programming for it. But,

15:26

um, yeah, in the end, I think we ended up spending

15:29

maybe $7,000 in parts and we had about

15:32

six months of my time, but we are

15:34

now on version four of a cake cleaner and it's

15:37

working great.

15:40

So, uh, so you got through this initial

15:43

startup and I assume you were profitable

15:45

at least initially, right?

15:47

Initially. Yeah. I mean, we're,

15:50

we still are for sure. Yeah. Yeah.

15:52

We're not going to, you know, retire any time soon,

15:55

but we're still having a great time doing everything.

15:57

Yeah.

15:58

But, um, so then you went through a, period,

16:00

you mentioned of, uh, you know, fairly rapid

16:02

growth. You went and got a SBA loan

16:04

and, uh, and, uh, expanded pretty

16:07

dramatically. What was that phase

16:09

like? Cause I've seen other breweries, you know, kind

16:12

of go through something similar, they go and raise a substantial

16:15

much amount of money and in some cases don't

16:17

make it. So, um, so tell

16:19

us a little bit about how, uh, how you managed

16:21

to do all that.

16:22

Sure. Um, yeah. And I've

16:25

seen the same thing, even in Kansas, so there has

16:27

been a few breweries that, uh, try to

16:30

take off more than they can chew to begin

16:32

with. And we were very aware

16:34

of that.

16:35

So our growth was well, it was fast,

16:38

I guess in terms of where we started. Uh, we

16:40

did take things pretty

16:42

methodically, so we would expand

16:45

in one area. Uh, for instance, our home markets,

16:47

Wichita. So we would

16:49

find, you know, the top 20 accounts out

16:52

there and try to get into those.

16:54

And then we all, once we're happy with that,

16:57

we move out to another 20. And

16:59

once we kind of got most of Wichita covered,

17:01

then we went to the next big town. But

17:03

you know, over a period of probably two years, we

17:06

went from just a couple of bars

17:09

to statewide. How

17:11

do you do that? I mean, how do you break into,

17:14

uh, some of these big distribution chains

17:16

that are

17:17

honestly dominated by a few large brands?

17:19

Yeah, it can be

17:21

tough. Um, well, the way

17:23

that we ended up doing it, uh, we're lucky

17:26

that at the time we really started to

17:28

distribute, um, Kansas

17:30

was really starting to explode with, with more

17:33

smaller breweries. And

17:36

our distributor network, um, actually

17:38

has a little, a little side group called

17:41

the Kansas craft Alliance. It

17:43

is kind of a collection of all

17:45

the distributors that want to deal with craft

17:48

beer.

17:49

So we actually just had a single point of contact

17:51

at the, at the craft Alliance. And

17:54

they were able to do all the negotiations

17:56

for us with all the other distributors.

18:00

So, so you were able to break

18:02

in to those very difficult markets

18:05

that way, I guess. Yeah. There's

18:08

definitely a good, a good way to get into it. There's

18:11

still a lot of tough areas, especially in Kansas.

18:14

You get into the rural

18:16

areas and craft beer is not the,

18:18

you know,

18:19

the drink of choice. Interesting.

18:22

Was, was it hard to,

18:24

to, well, I guess what

18:27

trophy to switch bottles? I mean, cause obviously originally

18:29

you were using more of a, you know, kind of a tap

18:31

room, a self distribution model, which is,

18:34

which is obviously much more profitable. What made

18:36

you decide that you wanted

18:38

to go over to,

18:40

you know, commercial distribution where you have to can

18:42

and,

18:43

and, and obviously the profit margin is much, much lower.

18:46

Yeah, they are.

18:48

Was it, was it mainly the laws

18:50

there or? Not

18:53

necessarily. We were, I guess,

18:56

expecting more of a, of a

18:58

customer following here in El Dorado

19:00

or

19:01

our projections for

19:03

what we would do in revenue through the tap room

19:06

or probably, you know,

19:08

half or twice of what we, what

19:10

we really saw. The

19:12

town really itself isn't that big. I think

19:14

we are at about 13,000 people in El Dorado. Yeah.

19:19

And even though we're still fairly close to Wichita, I mean,

19:21

it gets a short drive,

19:23

but people still aren't willing

19:25

to drive for 20 minutes to

19:27

get a beer and then then drive back. So

19:31

we decided that, you know, the best way to

19:33

make more money is to get more volume out there.

19:36

And that's the way to do that is

19:38

in cans and distribute. So

19:40

that's what you did. Yeah. So you

19:42

did eventually open a restaurant. Did you open it

19:44

in, in El Dorado or did you move it somewhere

19:47

else?

19:47

It is actually in downtown Wichita.

19:50

That is

19:51

what we consider to be our home market. We probably sell 80%

19:53

of our volume there.

19:57

So that just made the most sense to

19:59

do it. That makes sense, yeah.

20:02

Well, let's talk a little bit about beer

20:04

and brewing. What does your original

20:06

lineup of beers look like, and how did

20:08

you decide to choose those beers?

20:11

Oh, lots of market

20:13

studies. We probably spent,

20:16

before we actually opened our doors, I want to say we probably

20:18

spent two years doing test batches,

20:21

lots of tastings. We're breeding in

20:23

local homebrew clubs. Really,

20:26

anyone in the area who

20:28

is willing to come over and taste beer, give

20:30

us feedback. In

20:33

the end, we had decided to think on five

20:36

flagship beers, which included,

20:38

of course, an Irish stout, a

20:40

wheat beer. Okay, you

20:42

got a wheat beer in Kansas. We

20:44

just had, I

20:46

think, a blonde, that

20:50

we, our main beer, we thought we

20:52

were really going to take off with, was a California

20:54

common. And

20:57

we also had a couple of- A good old steam beer, huh?

20:59

Yeah, good old steam beer. You just don't see it much around

21:01

here. No.

21:03

But yeah, so we started

21:05

off with that. And surprisingly,

21:09

our steam beer just kind of

21:12

sat there. Nobody really cared for it. I

21:15

thought it was a good solid steam beer, but

21:18

yeah, nobody wanted it.

21:20

But they

21:22

loved our Irish red. That was just kind of

21:24

in the initial lineup.

21:26

And I think

21:29

that's still one of your more popular beers, right?

21:31

If not your top selling beer.

21:32

Yeah, it became our top

21:34

beer very quickly. It is

21:36

still probably 60% of our sales.

21:39

And yeah, if that is actually

21:41

our top, I think the top selling

21:44

craft beer in Kansas. That's

21:48

pretty fantastic that you went from

21:51

humble beginnings 10 years ago to have

21:53

one of the top selling craft beers.

21:56

Yeah, thanks. So how

21:59

did things evolve over-

21:59

over time. Did you bring

22:02

in some of the new trends like the IPAs?

22:06

Oh, definitely.

22:09

Of course, we're doing our best to

22:11

follow the trends. It's

22:13

a little tough for me personally. I'm very

22:16

much a traditionalist when it comes to beer styles.

22:19

Okay. But we have actually a lot

22:21

of younger guys on

22:23

our crew.

22:26

One of our other business partners is

22:28

a microbiologist. And he

22:30

is really into all these eclectic

22:33

brews. So all the

22:34

Northeast IPAs, you know, fruited

22:36

sours,

22:38

all that kind of fun stuff. And

22:41

so I kind of hand the wheel off to him when it

22:43

comes to doing

22:44

all the new interesting styles.

22:47

But if you want traditional

22:49

stuff, you know, that's still in my wheelhouse. So

22:52

what does your lineup look

22:54

like today? And how's it different from maybe

22:56

what you had 10 years ago? We

22:59

do have quite a few sours now on tap.

23:01

Our latest one is actually a plum

23:04

sour, which is quite popular

23:06

in our area.

23:09

We do, let's see, we have, I think,

23:11

currently like four IPAs on tap.

23:13

Let's

23:16

see.

23:18

That also includes a Belgian triple we have.

23:21

We have a Russian Imperial Stout.

23:24

We have one called Ridiculous,

23:26

which is kind of its own thing. It's

23:29

probably closest to like an American Strong Ale.

23:32

Yeah.

23:34

So you've got quite a broad

23:37

selection now, right? Yes,

23:40

yes. And are you selling all those through cans

23:42

or primarily on tap? We

23:45

usually do, I think right

23:47

now we have about 10 varieties in

23:50

cans out in the market. That's

23:52

pretty broad, yeah. Yeah, that's

23:55

great.

23:56

Well, you credit your local water

23:58

is a key to your success.

23:59

What does it look like and how important

24:02

is it adjusting your water to get

24:04

great beer?

24:05

Well, of course, good water is

24:08

essential for making great beer.

24:11

When we were looking at Wichita water,

24:13

pretty much every brewery

24:15

in that area had to do a lot of fancy

24:17

footwork to make it work for brewing. Usually

24:20

reverse osmosis, adding back in all

24:22

the minerals and salts you need. In

24:25

El Dorado,

24:27

the water source is completely different. It flows down

24:29

through what we call the Flint Hills, which essentially

24:32

is large open

24:33

pasture lands that

24:36

are primarily limestone.

24:39

It picks up all kinds of nice little minerals and calcium

24:42

along the way. By the time

24:44

it reaches us,

24:45

it is actually exceptionally soft water with

24:48

low sulfites and everything in it. All

24:51

we have to do to it for almost all of our

24:53

beer styles is we run it through a charcoal

24:55

filter to remove the chlorine.

24:59

It's rare that we even have to touch it.

25:01

Interesting. So you don't do a lot of water adjustment

25:04

off the base water then?

25:05

Not for most of our styles. If we're doing

25:08

things like hazy IPAs, then yeah, we do have

25:10

to go in there and tweak all the sulfite levels.

25:13

Right. That makes sense.

25:15

So how's that different than you said the

25:17

Wichita water is bad. Does it have too much

25:20

of what? I don't know. Sulfite?

25:22

The biggest

25:24

issue with that is

25:27

the reservoir for Wichita is surrounded

25:30

by agricultural land. So

25:32

all the fertilizers and everything are run off

25:34

into the lake and the lake is nice

25:37

and shallow as well. So it gets plenty of

25:39

daylight. What happens

25:41

is as soon as the weather starts warming up, you get algae

25:43

blooms and the water just

25:45

actually tastes horrible.

25:47

Interesting.

25:48

Not good. No.

25:52

So I mean you've

25:54

gone from humble beginnings now to the top

25:56

selling Kansas craft beer.

26:00

Can you tell us a little bit about your top selling

26:02

beer?

26:03

Absolutely. It

26:05

is an Irish red. It's a little non-traditional.

26:09

We've tried to enter it into a bunch

26:11

of contests, but it's just slightly out of style.

26:13

So it doesn't, it doesn't fare well for

26:16

strict judging, but it sells

26:18

incredibly well, which is of course, we want to

26:20

make our customers happy. But it

26:23

is

26:24

a fairly rich version of an Irish

26:26

red. Nice

26:30

of course, multi, very low bitterness.

26:33

If you put it together with

26:36

say, you know, your more traditional

26:38

Irish red, say a Killian, just what most

26:40

people think of it probably.

26:43

Killian seems to be pretty thin and watery

26:45

and over carbonated compared to ours, but

26:48

ours is nice, rich and multi,

26:51

low bitterness. It's very easy to

26:53

drink. You can sit there and drink multiples

26:55

of it. I mean, it's only five and a half percent.

26:58

And yeah, people love it.

27:01

That's awesome.

27:02

That's great. What's your second

27:04

top selling beer?

27:06

At the moment, it is

27:08

a Kolsch.

27:10

It kind of depends on the

27:12

season as to what our second one is. And

27:15

more of the wintertime or IPA, we have

27:17

one called a high beam IPA. It's kind of a traditional

27:19

West Coast. That one

27:21

becomes number two. Now,

27:24

the weather's warming up.

27:25

It's now gonna be our tea to rock Kolsch.

27:27

Kolsch

27:30

is a difficult

27:33

style to brew and make it perfect.

27:36

What are some of the secrets to making that work?

27:39

For us, it's making sure

27:41

that of course, you have nice clean yeast

27:44

in it. Really control your fermentation

27:46

temperatures. Do all

27:48

the standard things you need to keep your yeast

27:50

happy, which of course for us is

27:53

plenty of oxygen whenever you're transferring the work

27:56

from the kettle to the fermenter. Yeast

27:58

nutrient for sure. and

28:01

just really monitoring your yeast performance

28:04

over generations.

28:05

Luckily with

28:07

our microbiologist on staff, he can really kind

28:09

of watch that and we were able

28:12

to usually get 10 to 12 generations out

28:14

of a yeast patch before we have to get a new

28:16

one.

28:17

So it's kind of- So you do reuse your yeast obviously.

28:19

A lot of commercial brewers do obviously, but-

28:22

Yeah, yeast is actually one of the highest cost items

28:24

out there, so we

28:27

do our best to reuse that as much as possible.

28:29

Interesting, and are you using a lot

28:31

of other ingredients for,

28:33

you know, for example, when you make a colesher, are you using

28:35

German malt or how are you sourcing

28:37

your ingredients?

28:39

Most of our malt actually comes

28:41

from Canada, strangely enough. Import

28:44

malts, of course, the price of everything went so

28:46

high that we just have to

28:48

make do with what we can get at a reasonable price.

28:50

But just

28:53

the Canada-based

28:55

pilsner malts really seem to work just fine for it.

28:59

Have you jumped

29:01

on the logger train either? There's a

29:03

lot of craft breweries now that are

29:06

getting into making, you know, fine, high

29:08

grade continental loggers now.

29:10

Absolutely. We are playing

29:12

around with the Mexican logger. That seems

29:14

to be doing pretty well. We've

29:17

done a few of the test batches on it and got really great

29:20

feedback on it.

29:22

Actually, we're taking a little bit different approach,

29:25

I think, on our production side. We

29:27

do have a little bit of extra capacity, so

29:30

we are

29:31

testing the waters on doing contract brewing.

29:34

A lot of those

29:36

customers are actually wanting to do loggers because

29:38

they don't have the space for them. We're the time

29:40

to type for them.

29:42

Yeah, so we've done a couple of those

29:44

loggers so far

29:45

and it's been actually a good experience.

29:47

So interesting. So you're actually contracting

29:50

out your facility for other people to gypsy

29:53

brew, I guess then. Is that right?

29:54

That's exactly right. Interesting.

29:57

And so you

29:59

must have some excess capacity. capacity there.

30:01

Yeah, at the moment we

30:04

probably have about 40% of our capacity

30:06

still there. And we actually did that

30:08

in the beginning as part of the brewery

30:10

design. We wanted to make sure that

30:13

if we did decide to go into new markets,

30:15

whether it be a different state or whatever,

30:18

we wanted to have that capacity there

30:20

without needing to beef up

30:23

our infrastructure and spend money we didn't have

30:25

to.

30:27

So do you think the Kansas laws helped drive

30:29

you towards not

30:32

doing just a tap room and drive you into

30:34

distribution or not?

30:36

That's kind of a funny story.

30:38

In the beginning I wanted to do

30:41

just a tap room with a

30:43

restaurant along with it. So just a small brew

30:45

pub in El Dorado, Kansas. That was

30:47

my idea. My business partner

30:50

didn't want to have anything to do with a restaurant. He's

30:53

like, I don't know the food industry. The failure rate is

30:55

so high on those. I don't want to touch it. So

30:59

we had to negotiate and it was,

31:01

okay, we'll start with the production brewery,

31:03

make that work first,

31:05

and then maybe add on something or

31:07

later. And I know it took me

31:10

a few years, but I got my way.

31:12

Interesting. So you did. So

31:14

tell us a little bit about the restaurant and how that that

31:16

came out and how it's working for you. Okay.

31:19

Yeah. Um, so the restaurant,

31:22

of course, um, we got to a point with the

31:24

production brewery where we were pretty

31:27

much statewide are

31:29

our areas of growth, at least in Kansas are

31:31

not that great anymore. So we were, we were looking better,

31:34

uh, better ways to, to expand our

31:36

production. And

31:38

it was right about the time where you saw a

31:40

lot of the bigger breweries that

31:42

were multi-state starting

31:44

to either fail laps. They'd just

31:47

have a big downturn.

31:49

And I thought it was well, obviously trying

31:51

to push out into another state may

31:54

not be the best idea at this, at this time.

31:56

And our best market is local. And of course,

31:58

those are the people who know. us. So

32:01

let's look at a local restaurant. And

32:03

of course, we already knew from our tap room, the

32:06

Eldorado, you know, well, a great place to be

32:08

as a brewery may not be the best place

32:10

for a restaurant. So we

32:12

went to our hometown, Wichita,

32:15

and right in the middle of downtown where there are

32:17

several of the breweries right in the same area.

32:19

And so

32:22

we've actually

32:23

got a place in an old train station that

32:26

we're leasing and

32:29

created a restaurant right there.

32:31

It's actually really good food. We got some, some great

32:33

staff there. I'm hired a good chef.

32:37

Yeah, we have, you know, really great food, really

32:40

great beers there. For

32:42

quite a while, we actually brewed on site

32:46

and it was

32:48

a small enough space there that it was

32:50

more of a hassle because I didn't

32:52

have enough space to really work. And

32:54

what I would end up doing was throwing a hose out in the middle

32:56

of the hallway and then the staff would

32:59

trip over it. But uh,

33:01

so

33:04

you ended up, uh, you said you have closing the production

33:06

there, I guess. And he also had the water problem you mentioned

33:09

too. Yeah, yeah. We actually had

33:11

a better, a smaller Oso system there to be

33:13

able to, to, to get

33:15

water to brew. And it took

33:17

probably three or four hours to fill our two barrel

33:19

tank to brew on, on site. So

33:22

it was just more of a pain than anything else. And

33:25

turns out we could actually contract a brew to ourselves.

33:28

So we just moved our, our

33:30

two barrel system, which was still our original one,

33:32

um,

33:33

back to our main brewery and did

33:35

our batches here and just

33:38

contract brew to ourselves. And it was great. That's

33:40

good.

33:41

And the restaurant overall has been a success, I guess.

33:44

Yeah, see we've been doing really well. Um,

33:47

we had great reviews so far. Um,

33:49

say right now where we put open almost five years.

33:51

So yeah, well, it's

33:53

hard to believe that, but yeah, five years.

33:56

So how did, uh, uh, did COVID

33:58

affect you?

33:59

Obviously everybody was hit pretty

34:02

hard during COVID.

34:04

Obviously you were a production brewery at that

34:06

point, so you probably weren't hit quite as badly,

34:08

but

34:09

what were some of the adjustments you had to make?

34:11

Yeah, COVID was pretty horrible for the

34:14

restaurant. The main brewery wasn't too bad.

34:16

We just learned that we just needed a shift

34:19

from kegging beer for restaurants

34:21

and bars into more cans. I

34:24

mean, everybody was still drinking, they just did it at home. So

34:26

from the production side, it wasn't too big of a deal.

34:29

The restaurant was a whole different experience.

34:33

Nobody came in.

34:36

Essentially our income almost went to zero.

34:38

We did all of the emergency

34:41

relief funds and everything that we could

34:44

just keep the bills paid. Check

34:46

out a few loans on that one. And I

34:48

mean,

34:49

it worked out, but for about

34:51

six months, we were down to a crew

34:53

of two people and we just had to go orders.

34:56

And yeah, I mean, it was pretty

34:58

horrible.

35:01

But of course, whenever you

35:02

came back out of it,

35:05

started opening up the restaurants again, then

35:08

we still have issues trying to hire staff.

35:11

That's ongoing problem for everybody, I

35:13

think. Yeah, are you still having some staffing

35:15

issues? I know a lot of people I talked to

35:18

are having trouble getting people in.

35:20

It's definitely a challenge.

35:23

If somebody leaves, it's tough to find

35:25

somebody that really still wants to work

35:27

and does a good job, but it's

35:29

getting a lot better.

35:32

Well, you started on shoestring, and so I

35:34

wondered if you had any advice for somebody

35:36

looking to go professional, perhaps, from

35:39

a business perspective.

35:41

Absolutely. Really,

35:43

I think it's a matter of passion

35:46

and willingness

35:48

to do a lot of sacrificing. I

35:51

mean, if it's really important to you to

35:53

do brewing as a business, I

35:55

have learned that you're not gonna get rich doing

35:58

it. It is something that is...

35:59

It's a subject of love.

36:02

If you love great beer and you want to share

36:04

that passion with other people,

36:06

you know, get into it. Just

36:08

be prepared that it's gonna be a lot of long

36:11

nights,

36:12

long days, long weeks,

36:14

long years probably. And

36:16

yeah,

36:18

you're gonna have to figure out how to fix things

36:20

with no money and

36:23

just keep plugging away at it.

36:25

And I assume the challenges, yeah, from people

36:28

I've talked to, the challenges continue because even if you

36:31

raise a big chunk of money somewhere,

36:33

you still kind of have to work

36:35

through all the challenges with

36:37

the people that loan you the money in the first place, right?

36:39

Absolutely. We

36:42

do have a group of

36:44

investors in our brewery now.

36:46

So as we moved along,

36:48

we actually did bring in a few people

36:51

that really helped us out and let us

36:53

purchase a new canning line

36:55

and

36:57

try to deal with a lot of the challenges.

37:00

I know a lot of the production guys out there will know

37:02

about all the aluminum can shortage

37:05

and issues that are going on with those.

37:08

And that's still a big problem.

37:13

Yeah. The supply chain

37:15

still has some kinks in it, I think.

37:18

Yeah, yeah, that definitely does. Yeah.

37:21

Well, Tina, Tina, taken

37:23

from a brewer's perspective, perhaps, and

37:26

what are some of the keys to success purely

37:28

from a brewing perspective? Because obviously the beer

37:30

has to be good.

37:32

Absolutely.

37:34

For us, I want to say our

37:36

big thing is consistency. That's

37:39

what I hear really time after time about our

37:41

beer is that no matter when you pick up one of

37:43

them, our batches are consistent.

37:47

Of course, the quality has to be there for sure,

37:50

that kind of goes with, I think, good

37:52

practices. For us,

37:54

it is about making sure

37:57

your yeast is happy and healthy.

38:00

Making sure, of course, everything is clean, just

38:02

like

38:03

you'd expect. Temperature

38:06

control during fermentation is absolutely huge.

38:11

Making sure all your ingredients are quality.

38:14

Of course, it's always a

38:17

fine line there between price and

38:19

quality, so you have

38:21

to really watch it. But, yeah.

38:24

Lots of challenges. So,

38:26

you're big in Kansas, obviously.

38:28

Have

38:33

you looked at expanding in other states, or are you primarily

38:36

focused on distribution in Kansas?

38:39

We have looked at a couple other states. We were

38:41

in Wyoming, of all places, for a

38:44

little while.

38:46

But our distributor decided to

38:48

go out of business there, and they

38:51

handed us off to a different distributor

38:53

who wasn't all that great. So

38:56

from what we can tell, really moving into

38:58

other states, the big challenges we have

39:01

there are finding a good distributor

39:03

to partner with. And

39:05

unfortunately, you just don't know until you start

39:07

working with them.

39:08

But currently,

39:10

we are, say, throughout Kansas, and

39:12

we are also in Missouri as well.

39:15

Great.

39:16

That's awesome. Well, can

39:18

you tell folks where your brewery is located and where

39:20

your website is so they can find you?

39:22

Absolutely. We are in El Dorado, Kansas. Actually, we're

39:24

right in the middle of downtown. If

39:27

you ever want to come

39:29

by the taproom, get a tour or whatever, you're more

39:31

than welcome to. Our

39:33

website is at waldutriverbrewing.com.

39:37

And if you ever want to find out where our beer

39:39

is at, there is an app on

39:42

there called Beer Finder. You can click

39:44

on it and throw in

39:46

your location, and it'll tell you what liquor stores,

39:49

restaurants, whatever, where we're

39:51

at.

39:52

That's awesome. And I wanted to get

39:54

your closing thoughts after demonstrating

39:56

that you don't need millions of dollars

39:58

to start a great brewery.

40:00

Yeah,

40:03

so if you want to get into this, you just got to be patient.

40:06

Try not to reach too far too fast.

40:09

I say I've seen at least two

40:11

breweries in our area fail just because they tried

40:13

to grow too quickly.

40:16

It's just a matter of being

40:18

patient and diligent.

40:20

Interesting. Well,

40:23

Rick, I really appreciate you coming on the show. Thank

40:25

you so much for being here today.

40:27

Yeah, thank you very much for having

40:29

me. And my guest today was Rick Gehring, head

40:31

brewer and founder of Walnut River Brewing

40:34

Company in El Dorado, Kansas. Thank

40:36

you again, Rick.

40:37

Thank you.

40:39

A big thank you to Rick Gehring for joining me this

40:41

week. Thanks also to Craft Beer & Brewing

40:44

Magazine. They offer access to videos,

40:46

brewing courses, exclusive articles, and

40:48

the amazing Craft Beer & Brewing Magazine.

40:51

Go to beerandbrewing.com to get your subscription

40:54

today.

40:55

And also Beersmith Web, the online version

40:58

of Beersmith Brewing Software. Beersmith

41:00

for the web lets you design great beer recipes from any

41:02

browser, including your tablet or phone.

41:05

Edit recipes on the go with access

41:07

to tens of thousands of recipes as well as the full suite

41:10

of recipe building tools. Try

41:13

Beersmith Web today by creating a free account

41:16

at beersmithrecipes.com.

41:19

And finally, a reminder to click that like

41:22

or subscribe button on YouTube, iTunes,

41:24

Spotify, or whatever platform you're listening

41:26

on,

41:27

as it really helps us bring new listeners in.

41:30

I'd like to thank you for listening. I hope you have

41:33

a great brewing week.

41:55

Cheers. Cheers. Cheers.

From The Podcast

BeerSmith Home and Beer Brewing Podcast

The BeerSmith Home Brewing Show is a beer brewing podcast focused on how to brew beer, homebrewing techniques, and beer stories from top US and international brewers. In each episode we bring you an interview with guests assembled from around the world to talk about beer, craft beer and homebrew. The BeerSmith podcast is hosted by Dr Brad Smith, the author of BeerSmith homebrewing software, the book Home Brewing with BeerSmith, and the BeerSmith blog which attracts over 200,000 readers monthly. Website: http://BeerSmith.com/blogJoin Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

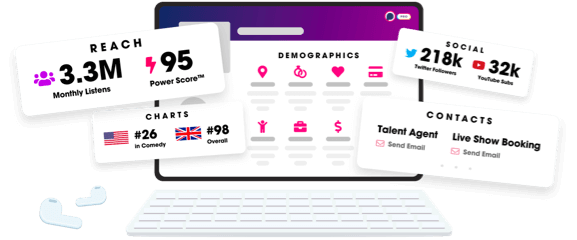

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us