Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:00

Andrew Burns joins me this week to discuss

0:02

technical programs in brewing. This is

0:04

Beersmith Podcast number 297. And

0:30

it's late January, 2024. Andrew

0:32

Burns joins me this week to discuss technical

0:34

programs in brewing. Thank

0:37

you to this week's sponsors, Craft

0:39

Beer and Brewing magazine. They invite you to

0:41

join their upcoming brewery workshop, March 24th, the 27th

0:43

in Austin, Texas. This

0:45

one of a kind event brings together

0:47

professional brewers to help you start your own business. This

0:50

is Beersmith Podcast number 297. And

0:53

it's late January, 2024. Andrew

0:55

Burns joins me this week to discuss technical

0:58

programs in brewing. Professional brewers to help you start and

1:00

grow your own craft brewery. To

1:03

learn more, please visit

1:05

breweryworkshop.com. Again, that is

1:07

breweryworkshop.com. And

1:10

also the barrel mill created the infusion

1:12

spiral used to add flavor and aroma

1:14

to wine, spirits, and beer. The New

1:16

York's unique spiral cut design creates unrivaled

1:18

surface area in a small package, allowing

1:21

fast extraction of the toasted oaks aroma

1:24

and flavor compounds. Looking for

1:26

woods other than oak? Try our exotic woods

1:29

involving spirals made from amberana,

1:32

American or French oak, aspen, Spanish

1:34

cedar, cypress, and sugar maple. For

1:37

more information, go to infusion

1:39

spiral.com. Again, that's infusion spiral.com.

1:43

And Beersmith Web, the online version of

1:46

Beersmith Brewing Software. Beersmith for

1:48

the web lets you design great beer recipes from

1:50

any browser, including your tablet or phone. Edit

1:53

recipes on the go with access to the same

1:55

full suite of recipe building tools

1:57

as our desktop version. Try

1:59

Beersmith Web today. by creating a free account

2:01

at beersmithrecipes.com. And

2:04

finally, a reminder to click those like and

2:06

subscribe buttons on YouTube, iTunes, Spotify, or whatever

2:09

platform you're on. Clicking those buttons

2:11

is a great way to support the show. And

2:14

now let's jump into this week's episode.

2:17

Today on the show, I welcome Andrew Burns. Andrew

2:20

is the brewing instructor at Dakota County

2:22

Technical College, where they have a

2:24

one-year brewing science and production certificate. Before

2:27

becoming an instructor, he worked as

2:29

a shift brewer and a head brewer, and

2:31

he's also been home brewing for nearly 15 years. Andrew,

2:34

it's great to have you on the show for the first time. How are you doing,

2:36

sir? Hi, Brad. I'm doing well and

2:38

happy to be here. Awesome.

2:41

Are you, how are things up there? Now,

2:44

tell me where you are because Dakota College, somebody

2:46

might think it's actually in Dakota. Right,

2:48

yeah. One of the Dakotas. Dakota

2:50

County is one of the counties

2:53

right by Minneapolis and St. Paul, Minnesota.

2:56

So I'm here in Minnesota. I live

2:59

in Minneapolis and teach right here in the

3:01

metro area. Awesome.

3:05

And can you tell us a little bit about yourself?

3:07

Did you start, I guess you started home brewing first

3:09

or did you start writing to pro brewing? Yeah,

3:11

no, that's right. I home brewed for

3:14

many years as a hobby before making

3:16

the transition into professional brewing. I

3:19

started home brewing, you

3:21

know, when I was 21 years old in

3:23

college, living with some friends and we decided to

3:25

do it together as a hobby. And that

3:28

was when I was pursuing my first

3:31

career as a professional musician. So I

3:33

went to school for music and

3:37

became a touring musician and kind of did

3:39

that for a little while, all the while

3:41

home brewing as a hobby. And

3:44

right about the

3:46

2014, I decided

3:48

to transition out of touring and

3:50

playing professionally and try to pursue

3:53

beer as my

3:55

full time job. And that's when I

3:58

got some education and tried to make it. and

4:00

successfully made the leap from home brewer to pro

4:02

brewer. Cool. And where's your work

4:04

the first time? You said I think you started as a ship

4:07

brewer, right? Well, you know,

4:09

I've had a, again, sort of a

4:11

roundabout experience. My first job as a

4:13

professional brewer was actually as a head

4:15

brewer for a really small brew pub.

4:18

So it was a startup brewery in southern

4:20

Minnesota called Jaffa Brewing. And

4:23

I was the head brewer in as much as I

4:25

was the lone brewer. You know, a lot of these

4:27

small shops, you have one person running all

4:29

of the beer making operations from brewing to cleaning the

4:32

floors to kegging to serving the beer in the taproom.

4:34

So I did a little bit of all of that.

4:36

So you were janitor and head of operations, huh? And

4:39

IT department and HR. Yeah.

4:43

And then after doing that,

4:45

I wanted to get some experience at

4:47

a larger production facility. And so that's

4:50

when I went again in Minneapolis to

4:52

prize brewing. That's P-R-Y-E-S.

4:55

And it's sort of a mid-sized production brewery with

4:58

a really big taproom. You

5:00

know, and that's where we had shifts brewing. And I

5:02

started as part of the team there as a ship

5:05

brewer, you know, rotating through different stations

5:07

and different positions and then wound up

5:09

managing that breweries operation. So by the

5:11

end of my time with prize, I

5:13

was managing and training our team of

5:15

brewers. Wow. That's cool.

5:17

How big was that? How many people, how many

5:19

brewers, for example? With when I

5:22

left, we had six full-time brewers and then

5:24

me managing them as the seventh. So that

5:26

is a pretty big operation then, right? How

5:28

many barrels? It

5:31

was right around 10,000 barrels a year. That's

5:33

a big operation. Yeah. That's

5:36

awesome. And let's see,

5:39

you worked as a shift and head brewer.

5:41

What made you decide to dive into brewing

5:43

education now? Well, you

5:45

know, it's a funny story. I

5:48

think it took me a very long time to realize that

5:50

this was sort of the perfect position for me. I've

5:52

always loved teaching. Back when I

5:55

was a musician, I would teach private lessons. And

5:57

so I had a little bit of an education

5:59

background just from. from doing that. And

6:02

even working in beer, I maintained

6:04

a small roster of students for a few

6:06

years and then wound up

6:10

managing a team of brewers. And once again,

6:12

managing them being responsible for

6:15

the operations of the brewery. But a

6:17

lot of that was training, onboarding new

6:19

employees or training our existing employees and

6:21

new processes, new pieces of

6:24

equipment. And I kind of found that

6:27

that was the part I really loved the

6:29

most was sharing knowledge, teaching, and

6:32

even as not officially as a teacher, but

6:34

the times when I was teaching were sort

6:37

of the most fulfilling. And

6:40

yeah, so I just got lucky that this position,

6:43

opened up at the technical college where

6:45

they have a brewing program. And

6:47

I just felt I was really well positioned to

6:50

take my industry experience, sort of what I

6:53

knew from process and norms and

6:55

best practices of working at scale

6:58

and really pursuing my passion for teaching that

7:00

I had all along that took me a

7:03

really long time to figure out I should

7:05

pursue. Well, that's

7:07

great. So tell us

7:09

a little bit about Dakota County Tech. We were

7:11

talking, I think before the show, you mentioned, it

7:13

was sort of a community college level program, right?

7:16

Yes, so DCTC is a one in

7:18

two year technical college, you

7:22

know, like a one in two year technical

7:24

college, you know, near Minneapolis.

7:28

And the

7:30

brewing program has been around for

7:33

several years and it's kind

7:35

of unique amongst brewing programs. We

7:38

have a one year or one school

7:41

year program that's designed for people who

7:43

want to learn more about beer, learn

7:45

more about beer making and brewing, maybe

7:48

probably work in the industry, if

7:51

not initially, maybe one day. So

7:53

that could be just people who want to have a

7:55

job in a brewery, you

7:57

know, work as a brewer. or

8:00

some other production-focused job, or maybe run a

8:02

brewer. Maybe they see themselves as a head

8:04

brewer someday, or maybe even an owner. There's

8:09

a fair amount of my students

8:11

who are experienced home brewers, and

8:13

they want to, they

8:15

kind of want to find out what they don't know

8:17

about the industry so that they can be prepared to

8:21

make a career change. That's a common story

8:23

we hear in brewing, is it's often not

8:26

someone's first career, it's often a

8:29

career change, just like it was for me, my

8:31

first career was a musician, and I wound up

8:33

in brewing as sort of following a passion there.

8:36

So it's a one-year program, and

8:38

starting this upcoming school year,

8:41

so starting in August for

8:43

the fall semester, we'll actually have

8:45

two separate programs that are essentially

8:47

the same curriculum, but

8:50

maybe serve two different needs. We've got our

8:52

flagship one-year program, which is in-person

8:55

here on campus. We actually brew

8:57

on-site, we've got some sort of

9:01

really nice pilot brewing systems and

9:03

Conical for Mentors to sort of

9:05

emulate the commercial brewing process right here

9:07

on campus, and so as part of the

9:09

curriculum, it's hands-on learning, and

9:12

that happens here on campus, like

9:14

I said, it's one school year, and

9:16

then we'll be launching an online-only

9:18

program, so hopefully extend the reach

9:20

to people who are interested in

9:22

brewing education, but maybe can't get

9:24

here every week for their in-class

9:26

instruction. They could do the

9:29

same curriculum, same concepts, but just all

9:31

online, so there'll be

9:33

a 100% online option launching this

9:35

fall. So when you say

9:37

it's a certificate program, I assume it's not an

9:39

associate's degree, right? Yes, that's right.

9:41

Why your certificate? Right, it's

9:43

a one-year certificate, it's not an associate's degree,

9:45

it doesn't require any gen eds or extra

9:48

college classes or liberal arts or anything like

9:50

that. So you just focused on brewing for

9:52

the year, and I think I read somewhere,

9:54

it was on the weekends too for people

9:56

that are local. Yeah, that's

9:58

right, so for people here in... Minnesota,

10:01

we expect that our typical student probably

10:03

has a day job. In fact, some

10:05

of them are working in breweries already,

10:07

or they sort of quit their day

10:09

job, go get a job as a

10:11

packaging tech at a brewery and sign

10:13

up for this program sort of all at

10:15

once. But the

10:17

idea is we run it all on Saturdays.

10:21

You know, the program is aimed at

10:23

adults, you know, you have to be 21

10:25

to even enroll in the program.

10:27

So nobody's coming straight out of high school and

10:29

going into this type of program.

10:31

So we expect you to have a, you

10:34

know, probably have a day job. So we're not going to

10:36

try to interfere with that too much. We

10:38

run all of the in person classes

10:40

on Saturdays. That

10:43

must be that's pretty convenient then if you're if

10:45

you're a full time job or whatever regular job,

10:47

right? Oh, right. Yeah, I mean, that's

10:49

yeah, that's the goal. Yeah.

10:52

Well, you mentioned you were a long time home

10:54

brewer. Let's say somebody was a also a reasonably

10:56

good home brewer looking to go pro. What

10:59

kind of advantage would they get from from signing up

11:01

for a program like yours? Well,

11:03

um, I think there's a ton

11:05

that I'm a little bit biased, obviously,

11:08

due to my position, but also this was the path

11:10

I took when I wanted

11:12

to make that leap from home brewer to pro brewer. I

11:16

went to Siebel Institute

11:18

in Chicago. Yeah. And it's time. The only

11:20

way to really do that was to actually

11:23

sort of quit a job and started a new

11:25

job so that I had a bank

11:28

of time where I could just leave

11:30

and go for several weeks and live

11:32

in Chicago and take these courses, nine

11:34

to five, Monday to Friday. It was

11:36

sort of a very compact, intense time

11:39

frame. But what it does

11:41

do is it I think it

11:43

introduces you to a lot of really, really

11:45

important concepts that you're going to need

11:48

as a professional brewer that might not be relevant

11:50

to home brewers. One of the

11:52

things I love about home brewing is

11:54

that the home brewing community has really adapted

11:56

the brewing process to suit the needs

11:58

of someone who's bringing it. home someone's

12:00

brewing in small scales compared to brewery

12:02

sized vessels. You

12:05

know maybe you're chasing fun

12:08

and flavor over repeatability and

12:10

quality and consistency or cost

12:14

and so a lot of the things that home

12:16

brewers do which I think are fantastic I think

12:18

it's the way that people should be

12:20

brewing at home aren't exactly the way we do

12:22

it at scale in the industry. I had to

12:25

unlearn or relearn a lot of habits in

12:29

particular just the way we control a

12:31

process how rigorous we are in terms

12:33

of testing and measuring and verifying is

12:36

quite a bit different at the professional scale.

12:38

There's also just things that aren't

12:41

feasible at a big scale

12:43

so we have to find alternative ways to deal

12:45

with them. And

12:48

so what I think

12:50

the formal education offers is some

12:52

sort of scientific grounding so you

12:54

understand exactly what's happening

12:56

in the brewing process and

12:58

can make adjustments to suit

13:00

your needs. And then an

13:03

overview of what are best practices

13:05

what our industry norms not every

13:07

brewery operates the same way and

13:10

so I view one of

13:12

the goals of education as presenting you

13:14

with a variety of options

13:17

and the variety of solutions that brewers have found

13:19

over the years and so you have the tools

13:21

to pick the one that matches your situation. You

13:24

know the way a

13:27

small brew pub that only sells directly

13:29

into their taproom develops

13:31

a recipe is probably quite a bit different

13:33

than the way a large-scale production facility that

13:35

brews multiple times a day and primarily sells

13:37

packaged product. It's just gonna settle

13:39

things. Yeah

13:42

so let's say I'm the opposite let's say I'm

13:44

a young person who maybe isn't in the home

13:46

brewing yet but it would like to work at

13:48

a commercial brewery someday. What

13:51

kind of experience would I get if I was

13:53

starting from scratch? Well

13:55

you know one of the things I like about

13:58

the beer industry is an education

14:00

is it required? It's

14:03

still an industry where you can sort

14:05

of begin with zero experience, find

14:07

a brewery usually in

14:10

packaging, be a department

14:12

that often hires people with sort of

14:15

no formal experience, and you can

14:17

just work your way up. You can sort of climb the

14:19

ladder. You can learn on the job,

14:22

but the reality of that is

14:24

that it's gonna take a long

14:26

time. Oftentimes breweries are

14:29

really busy. They're staffed just well

14:31

enough to produce

14:33

the amount of products that they need

14:35

to be producing, and there's not a

14:37

ton of time for shadowing and apprenticeship

14:39

or on-the-job training. I mean, that's

14:41

there and that happens, and that's sort of the traditional

14:43

path that a lot of today's head brewers took to

14:46

get to where they are, but more

14:48

and more what we're seeing is that

14:51

brewing education is a way to sort

14:53

of accelerate that time path. Instead of

14:55

spending maybe five years working in packaging

14:57

and working in the cellar and sort

14:59

of slowly gaining the knowledge and the

15:01

trust of a head brewer before you're

15:03

allowed to sort of transition to a

15:05

brewing role and work in the hot

15:07

side of the process, an

15:10

educational program like this could take just

15:12

one year and you're sort of ready

15:15

to make that leap. So

15:17

if you are a young person who is

15:20

21 and wants to work in

15:22

breweries, which I

15:25

encourage, I think it's a good career path

15:27

and maybe not a traditional career path that

15:29

many people are aware of, I

15:33

think the best way to do it is to just sort

15:35

of jump in, go

15:37

apply for those entry-level positions, just get in

15:39

and get there, get doing and working, and

15:42

at the same time if you can find

15:44

a way to squeeze education in, that's why

15:46

our program is scheduled the way it is.

15:49

You can really accelerate that and

15:51

move into more of the sort of

15:55

career type brewing positions

15:57

a lot faster. Well,

16:01

what kind of topics do you cover in

16:03

your technical brewing program? Well,

16:06

I kind of view it as sort

16:09

of four main areas of what we're

16:11

trying to do. So one of

16:13

the big ones is the science that's related to

16:15

brewing. So that is science

16:18

related to yeast and yeast health and

16:20

yeast fermentation, sort of the life cycle

16:22

of a yeast cell, so a lot

16:24

of biology involved with that. Science

16:28

like the chemistry in water, the

16:31

chemistry in the mash, sort of

16:33

the relationship between water

16:36

chemistry and mashing and what's happening

16:38

there with alkalinity and pH, as

16:41

well as looking at the enzymes that happen in the mash, sort

16:43

of all of that. And

16:46

then sort of the science of

16:48

what's happening in fermentation, aging, oxidization,

16:50

carbonation, what does volumes of

16:52

CO2 mean, how do we measure it. And

16:55

then there's the sort of the industry

16:58

norm practical knowledge, which is, okay,

17:00

so you've learned the science, the

17:02

foundation. Now this is what it

17:05

actually looks like. This is what it feels like. This

17:09

is what the life of a brewer with

17:11

the job of this other person actually entails.

17:15

Then we have the hands-on experience, which

17:19

in our case on campus, we have our brewing lab

17:21

where we have our pilot systems. And

17:23

then the fourth leg is the internship experience

17:25

or the industry experience. So as part of

17:27

the certificate, everyone who goes to our program

17:29

does an internship. So they go work at

17:31

a brewery that's local to them and

17:35

it can be a paid internship or an unpaid

17:37

internship. It really depends on the needs of the

17:39

brewery and the needs of the student. And

17:42

then they sort of bring all

17:44

that learning together, actually put

17:47

the boots on, get their hands dirty and see what

17:49

it's like to work in a production facility. Well,

17:52

that's really cool. Tell us a little more about

17:54

that hands-on program. So I'm kind of interested, are

17:57

you working at a craft brewery, I assume, probably. Yeah,

18:00

so for the most part, that's

18:02

the type of breweries, you know,

18:05

around where we are in Minneapolis

18:08

and the types of

18:10

breweries that are often willing to host and

18:12

want to host interns are small

18:15

craft breweries. Students

18:17

really do have the freedom to pursue

18:20

an internship with any brewery

18:23

that they are interested in. If, you know, I

18:26

encourage students to make those real

18:28

life relationships and to do, you know, go out

18:30

there, go talk to the head brewer or an

18:32

owner and say, hey, I'm in this program. I'd

18:34

like to do an internship here. What would that

18:36

look like? Could we make it happen? And so

18:38

one of the cool things is that students often

18:40

intern at breweries that they're a fan of. And

18:44

that's kind of exciting for everyone involved. A

18:46

lot of craft breweries, just

18:51

due to the numbers, you know, there's

18:53

a small number of production facilities that

18:55

employ a small number of brewers compared

18:58

to a large number of craft breweries.

19:00

Even if they're not making as many

19:02

barrels of beer, they employ a lot more

19:04

brewers, have a lot more room for interns

19:06

to come in. And honestly, that is the

19:08

type of students that I'm seeing is almost

19:10

entirely people who are interested in craft beer.

19:12

They like their small local breweries. They want

19:14

to see more of them in the world.

19:16

They want to work in them. They have

19:18

a passion for quality products. They want to

19:20

learn what goes into it. And so it's

19:22

just a natural fit to land at those

19:25

internships. Awesome.

19:28

Well, I want to go back and step up, walk through the

19:30

other three topics you talked about. The first one was science.

19:32

So can you talk a little bit, maybe a little more

19:34

in depth on what kind of science, you

19:36

know, you have to have a lot of math background. Is there

19:38

a lot of microbiology you got to understand

19:40

to be able to do this? So

19:44

you don't need a lot of math.

19:46

You don't need a heavy science background.

19:48

But if you do have those skills,

19:50

there are some really exciting careers in

19:53

beer that would pair really well with

19:55

the type of certificate we're offering. So,

19:58

you know, one of the career path

20:00

is if you have a background in science,

20:02

maybe you have an undergraduate degree in chemistry

20:05

or biology and you go, you know what,

20:07

I want to go work in beer and

20:09

breweries bring my science background

20:11

into it. A lot of breweries

20:14

have lab positions, quality positions, you

20:16

know, where a science background is really important and

20:19

in that regard I view my curriculum

20:21

that we're offering here at DCTC as

20:23

sort of, you probably

20:25

know more about biology and about

20:27

chemistries and a typical brewer, whatever

20:29

need to know. So here's the

20:32

beer specific knowledge that will be

20:34

really valuable for you. But

20:36

for the typical brewer, you

20:39

know, it's much more of

20:41

a conceptual understanding of what's

20:43

happening along with

20:46

a practical approach. So here is the

20:49

life cycle of a yeast cell, here

20:51

is how they're going to take in

20:54

sugar, they're going to produce these byproducts,

20:56

here's where acetaldehyde comes from, here's where

20:58

diacetyl comes from, here is where how

21:00

these, you know, flavorful molecules interact, here's

21:03

why these things are important and

21:05

now what does that look like in practice?

21:07

Well if you're in a brewery, these are

21:09

probably the processes you're going to be following

21:12

and so if you have that sort of

21:14

theoretical underpinning then

21:16

we can then move from there into

21:19

the practical approach and say, now that

21:21

you know all that, this is why we

21:23

do things this way as opposed to some

21:25

other way. You know and the same thing

21:27

with a numbers perspective, you know, you can

21:30

absolutely calculate out any

21:32

aspect of a beer recipe by

21:34

hand and it's a good exercise to

21:37

sort of understand how every

21:39

input could affect the output

21:43

of your beer. But at the end of the day, I tell my students,

21:46

software is probably going to be where you're going to

21:48

live. You're very unlikely

21:50

to be calculating recipes by hand

21:52

anymore. I don't know any brewers

21:54

who do that. I

21:57

know a few old-school ones but there are many. I

22:00

mean, once you get to know your system

22:02

well enough, you could probably write a recipe

22:04

by hand and say, I don't

22:06

know what the gravity exactly is gonna be. I don't know what

22:08

the color is gonna be, but I know this is gonna be

22:10

about right. And I don't know the specific numbers, but we could

22:12

brew it and it'll taste really good. But

22:15

when it comes to actually doing

22:17

calculations with water chemistry or making

22:19

adjustments to IBU based on hop

22:21

additions or just formulating a recipe

22:23

in the first place, we

22:26

work in software. And I train the

22:28

students. I give them a little

22:30

tutorial on how to use a beer Smith. I

22:32

encourage them to use beer Smith to

22:35

sort of calculate up their recipes.

22:37

And we use those calculators. Because

22:39

again, that's the practical approach where

22:41

practicality meets the science. It's important to

22:44

know why different water

22:47

ions are important. It's

22:49

important to know what impacts they're gonna have on

22:51

the flavor of the beer and the chemistry involved

22:53

with the mash. But it's probably

22:55

not important to know exactly how many parts

22:57

per million you get per gram of this

22:59

versus per gram of that. We can let

23:01

computers handle that. We don't

23:04

have to calculate the molar mass

23:06

and all that other stuff. Right,

23:08

it's just not, that's the practicality

23:10

aspect. That's that part of the curriculum

23:13

that says, okay, this is the theory, but what is

23:15

it actually, how do we actually put it into practice?

23:17

You're in a brewery, you're by yourself. You need to

23:19

figure it out. What are you gonna do? What tools

23:21

are you gonna reach for? Well,

23:23

I wanted to dive into that section next. So let's

23:25

talk about the practical. I assume this is where we

23:27

get into the real differences between home brewing and pro

23:30

brewing, for example, right? Well, yeah,

23:32

I mean, yeah. So

23:35

it's a lot of, you

23:38

know, we talk a lot about standard operating

23:40

procedures, SOPs, sort of why we do things

23:42

in the order we do them in. We

23:46

do address the differences between the home brewing

23:49

and pro brewing. Here on campus,

23:51

we have these 10

23:53

gallon pilot systems.

23:56

So about the home brew size, right? About

23:58

the home brew size. a really,

24:00

really nice homebrew setup or

24:03

a very, very small commercial setup, depending on how

24:05

you look at it, right? There's a little bit

24:07

of temperature control. There,

24:09

you know, it's a

24:11

continuous barging. You can, there's

24:14

a, we use an actual plate

24:16

heat exchanger to knock out the

24:19

work into conical fermenters. We have

24:21

glycol to chill the conical fermenters.

24:24

And so all of that feels very

24:26

much like commercial brewing. It's just at

24:28

the very small scale. Yeah.

24:30

Yeah. But you know,

24:32

when we talk about our processes, you know, how do

24:34

we clean up what chemicals are

24:36

using? What's the process for cleaning? We look

24:39

at that from the commercial brewing perspective. So

24:41

we're using things like caustic as opposed to,

24:43

you know, maybe PBW, which is a down

24:45

caustic cleaner. Sure. We're using

24:48

pumps and spray balls and

24:51

best practices when it comes to cleaning

24:53

our cold side equipment. It's still small,

24:55

which is great. It's low risk. It's

24:57

much more manageable and students get more

24:59

hands on time in the, in the

25:01

lab. You know, instead of having, say,

25:03

you could imagine a world where we

25:05

ran a one barrel or a three

25:08

barrel brewery or something like that. And we

25:10

just had the one brew house. But instead

25:12

we have six pilot systems, which means that

25:15

students get a lot

25:17

more time on an individual basis on the

25:19

systems and they get to practice brewing

25:21

recipes. They want to develop, they want to brew

25:24

and, and

25:27

getting that hands on time, which

25:29

then sets them up to

25:31

go into an internship and say, Oh,

25:33

I've recognized doing this. Of course, I did it on a

25:35

small scale. And now this one looks like it's a big

25:37

scale, but Oh, I recognize it. And

25:40

do you dive into like some of the new, you

25:42

know, new pro brewing craft, craft

25:44

techniques, you know, there's a lot of people

25:46

making hazy IPAs and other things using specific

25:48

techniques, for example. Yeah, we do

25:51

talk about that. And I do try

25:53

to stay current on those, on

25:56

those not fads,

25:58

but sort of new. adaptations, we

26:00

talk about it, we address it. I mean, you

26:02

brought up hazy IPAs, I think that's a fantastic

26:05

example. You know, a lot

26:07

of books that we read from or

26:09

for reading even slightly older sources, hazy

26:12

IPAs wasn't even a category of a

26:15

beer style, much less where their best

26:17

practices are sort of

26:19

this general knowledge on how to brew this

26:21

type of beer. So that's

26:24

a great example of

26:26

having to keep current. I have the

26:28

advantage of only recently leaving industry, so I haven't

26:30

been out of the game for very long and

26:33

I still try to keep current with that.

26:35

So yeah, you know,

26:37

we talk about, you know, conveyees,

26:39

we talk about seltzer

26:42

brewing, which is gigantic in the industry

26:44

right now. We talk about hazy IPAs,

26:46

you know, the different approaches, how you,

26:49

you know, how we would approach that

26:51

style of brewing and even into

26:53

equipment. Why would you choose this style

26:55

of brew house over another style of

26:57

brew house? Well, maybe this style of

27:00

brew house is really good for doing

27:02

more traditional styles with stepmashes, more of a German

27:04

tradition, whereas the styles are set up to brew

27:06

hazy IPAs. If that's what you're going to be

27:09

brewing, then that's sort of the equipment

27:11

you want in your dream brewing, right? Well,

27:15

you've been a, you've been a home brewer, you've been a shift

27:17

brewer and you've been a head brewer. What

27:19

are the different jobs like? Well,

27:23

you know, as a shift

27:27

brewer is

27:29

a lot of

27:31

what you're doing as a shift brewer is really

27:33

refining your workflow and refining your process. You

27:35

aren't generally choosing what gets brewed. You might

27:38

have one or two beers a year where

27:40

you get to write the recipe and have

27:42

some input. But for the most part, you're

27:44

brewing what you are being told to brew

27:46

and you are, and

27:49

your main thing is you're

27:51

following an SOP. So you

27:53

are, you intimately know

27:55

your system and your processes

27:58

and in any sort of long-term, larger scale production facility,

28:00

the shift brewers are probably the ones who know

28:03

all of the quirks of

28:05

the brew house, know exactly what

28:07

warning signs to look for if they're getting

28:10

a stuck runoff or know exactly how to

28:12

set a certain valve to get it to

28:14

work exactly perfectly. And so

28:16

if that, you know, it was really a

28:18

refinement of the process. And once you get

28:20

good at it, it's almost then you could

28:22

sort of brew, you know

28:24

exactly what's going to happen next. And so

28:26

you can sort of plan out your day,

28:28

set yourself up for success and sort of

28:30

everything goes exactly like clockwork. That

28:32

doesn't always happen. I mean, one of the big,

28:35

one of the differences between homebrew and pro brewing

28:37

is consistency, right? I mean, you're brewing the same

28:39

beer in many cases over and over again and

28:41

you want every batch to be exactly the same,

28:43

right? I mean, that's exactly right. I mean, not

28:45

even over and over again, maybe even multiple times

28:47

in the same day, right? You

28:50

know, it's pretty common for those sorts

28:52

of facilities to brew two or four

28:54

or sometimes even six batches a day.

28:58

And so oftentimes you're brewing, you know,

29:00

you are juggling multiple batches. That's the

29:02

other, that's sort of the other aspect

29:05

of shift brewing is that you get

29:07

so good at producing a

29:09

beer, at taking the raw ingredients

29:12

and turning them into work that

29:15

you can start to do more than one.

29:17

So you know, if you're working at a,

29:19

if you are a shift brewer, chances are

29:21

it's a production facility that runs multiple times

29:23

a day, which means you've probably

29:25

got one batch of beer that's further along than the

29:27

other and they're all going to go into the same

29:30

tank, but you are managing. Okay. So

29:32

this one is in the Whirlpool step right now.

29:34

Whereas this one, I am louder against barging and

29:36

I'm milling my third one for the day. And

29:39

you're, and you started doing a lot of that

29:41

multitasking and juggling, which requires a really intimate knowledge

29:44

of the process so that that frees up your

29:46

mind to focus on the, on that multitasking aspect

29:48

of it. As

29:50

a head brewer, you know,

29:53

in a small facility, you're often

29:55

the sole brewer. So, you know, if you

29:58

want to write a recipe and then go. execute

30:00

that recipe where it feels very much like home

30:02

brewing, you just get to do it every day.

30:05

That's kind of what a head brewer at a brew

30:07

pub is like with the

30:09

addition of you're also responsible for all

30:11

the clean and you'll probably spend

30:13

three times as much time cleaning all of

30:16

your equipment and cleaning your processes than you

30:18

are actually brewing or much less writing recipes

30:20

and ordering ingredients and that sort of stuff.

30:23

At a larger facility, one thing

30:25

that head brewers often realize is that at a

30:27

certain point they have to become a little bit

30:29

more hands off. You have

30:31

this devotion to quality. It's your

30:33

product. Oftentimes your name is on

30:36

the product and people know that

30:39

this is coming from you but you're not the

30:41

one who's actually on the brew deck brewing it.

30:43

You're not the one in the cellar who's making

30:45

sure that the tank is sanitized before it receives

30:48

the work. You're not responsible for quality over the

30:50

process. So a lot of what being a head

30:52

brewer is at that scale is

30:56

being a manager and a teacher and

30:58

a mentor and you

31:00

have to be involved enough

31:03

with the production process that quality

31:05

is being maintained. But

31:07

far enough removed that people can do their

31:09

jobs, that you're not interfering with the ship

31:12

brewers who like I said often have every

31:14

quirk of the brew house memorized far more than

31:16

the head brewer does because the head brewer is

31:19

more responsible for the big picture,

31:21

for quality from beginning to end, ordering

31:23

ingredients, setting up the schedule for what

31:25

gets brewed when, coming up with new

31:28

seasonals, writing new recipes, promoting the brewery,

31:30

all that other stuff that isn't actually

31:32

brewing. That's what I was wondering. Do

31:34

you cover a lot of the business

31:37

aspects of actually running a small brewery?

31:39

We cover enough of the

31:41

business aspects that we get an idea

31:44

of what it's like, but I am

31:46

not a business person. I'm a process

31:48

person. That's the aspect of the industry

31:50

that I'm an expert in and that's

31:52

really what the program focuses on. It's

31:57

not uncommon for someone who already

32:00

has a business background to

32:02

say I want to own a brewery and they come to

32:04

me and they enroll in the program so

32:07

that they can... Excuse

32:10

me I'm gonna cough here. I'll

32:15

start that sentence again. Yeah

32:20

we we talk about business and

32:23

we talk about the business of the industry

32:25

and what it's like at a surface level

32:27

and enough for you to

32:29

have an okay understanding what's happening but I'm not

32:31

a lawyer, I'm not an expert in beer laws,

32:34

I'm not a business person, I'm not an expert

32:36

in running a business, I'm

32:38

an expert in the process. I mean I know

32:40

there are some programs and courses that are centered

32:42

around opening your own brewery but obviously that becomes

32:45

you know a lot of it's not about brewing

32:47

really. Well that's exactly right

32:49

and so you know

32:51

I've had students who have a business background and

32:53

they decide that they want to open a brewery

32:55

so they come and enroll in the program so

32:57

that they can learn the beer specific aspects

33:00

of the industry to pair with their industry knowledge

33:03

or with their business knowledge. I've also got

33:05

some students who don't have much business knowledge

33:07

again they see themselves as brewery owners or

33:09

head brewers and so they

33:11

take some entrepreneurship and business classes at

33:14

the same time you know you know

33:16

being a community college and a technical

33:18

college like we are we have those

33:20

options and again it's pretty darn affordable

33:23

considering what the cost of college education is and

33:27

so that's another career path. Oftentimes

33:30

for successful breweries the

33:33

business person and the

33:35

head brewer beer person are not

33:37

the same person in that business.

33:40

That is it's

33:42

important for a head brewer to understand the business

33:44

of beer and the business of selling beer but

33:46

at large successful breweries even mid-sized

33:49

breweries that's often two different

33:51

people who wear two different hats and have two different

33:53

specialties. How

33:56

do you compare this program that you went through the Seibel Institute

33:58

how do you compare What do

34:00

they do with that program versus your

34:02

program, for example? Well, you

34:05

know, a

34:07

lot of the curriculum is essentially the same.

34:10

You know, we break it up into similar

34:12

chunks. We talk about an overview

34:15

and then we go into sort of

34:17

hot side work production. We follow that

34:19

up with a second semester

34:21

is more cold side and what

34:23

we call beer production, which into

34:25

packaging and quality control. And

34:28

so we cover the same sort of material

34:30

in the same general order, same type of

34:32

curriculum. Like I said, I went through part

34:35

of that C-Bolt program. The big difference

34:37

there is that their

34:40

program is very condensed in it from a

34:42

time perspective. So it's really well suited for

34:44

someone who's going to take time off work,

34:46

go do it, go do it all at

34:48

once, get it out of the way. So,

34:50

you know, you know, their

34:52

their flagship program in Chicago was six

34:55

weeks in Chicago followed by another six

34:57

weeks in Germany. That's their on the

34:59

job component is with some breweries in

35:01

Germany. And that's how they get the

35:03

on the job experience. What

35:06

we're trying to offer is as a counterpoint

35:09

to that is one

35:12

school year as opposed to short

35:15

number of weeks. So the idea

35:19

is we think it'll fit in the

35:21

working person's schedule. Sure.

35:24

And so we, you

35:26

know, the internship component

35:29

is not doesn't happen in Germany unless you

35:31

want it to happen in Germany. Right. But

35:35

you get to work with a local brewery

35:37

that that maybe interests you if

35:39

you can establish that relationship.

35:41

I have my own industry connection. So

35:43

I do try to set students up

35:46

with breweries that I know want to

35:48

take interns. But most students

35:50

find their own internship. That's right.

35:53

And then, yeah, and so really

35:55

the main

35:58

difference. is

36:02

just the mode of delivery. Yeah, compressed

36:06

program versus more of a traditional

36:08

schedule. But even so, one school

36:10

year, I mean, it comes up to 32 Saturdays. Yeah.

36:14

Or 32 weeks of online

36:17

instruction for the new online,

36:19

which by the way is fully asynchronous.

36:22

So it, you know, it's really you complete. You

36:24

gotta go at your own pace, I guess. Yeah,

36:26

each week's worth of work and readings and assignments

36:28

at the pace that makes sense for you and

36:31

your schedule. As long as you finish by the

36:33

end of the week, then you're caught up and

36:35

we go into the next week. Cool. And so,

36:37

yeah. Well,

36:40

let's talk a little bit about higher level

36:42

brewing degrees, like getting a bachelor's degree, maybe

36:44

from a big name like the University of

36:46

California, Davis. What would a bachelor's

36:48

degree or maybe even a master's degree add in

36:52

terms of brewing education? You

36:54

know, it really depends on what your

36:57

aspirations are in the brewing industry and where

36:59

you want to end up and what part

37:01

of the process really interests you. If

37:04

you are really into

37:06

quality and the lab

37:08

aspect of brewing, if you would want to

37:11

be this type of person who is running

37:13

the microscope and taking samples and making sure

37:15

that this batch is just as good as

37:17

the last batch, there

37:20

can be some real value in having that

37:22

sort of more formal bachelor's level education.

37:26

And there is a place for that in the

37:29

brewing industry. Like I said earlier, I

37:31

mean, many breweries have a lab or

37:33

quality department of some size, even if

37:35

it's just one person. But

37:38

often, as that person has a bachelor's degree

37:41

in a science field, you know,

37:43

biology or chemistry or like zimmergy

37:45

specific, yeast specific bachelor's

37:49

are really, really helpful and really valuable. Yeah,

37:52

I mean, there's a lot of programs now that offer

37:55

bachelor's degrees in brewing and brewing science,

37:57

for example. Right. Around here, again, I'm...

38:00

mostly know the job market in

38:02

Minnesota I

38:06

don't see head brewers being

38:09

more likely to hire someone to just

38:11

work in production as a ship brewer

38:13

or as an assistant brewer or as

38:15

a brewery manager or anything

38:17

like that I don't see them hiring

38:22

someone with a bachelor's degree over somebody

38:24

with some kind of experience That's

38:27

a good chance Which

38:31

is one of the reasons why we view this

38:33

program as a certificate Listen, it's

38:35

about getting you the knowledge and getting you

38:37

the practice and getting you your

38:39

foot in the door so that you

38:41

can accelerate your trip up to that

38:44

level of a job based

38:46

on real world actual brewing experience Which at

38:49

the end of the day, that is really

38:51

the most valuable thing for a brewer to

38:53

have in any capacity is that real experience

38:58

And that is probably, at least for now,

39:00

the way the industry is probably still going

39:02

to always be more valuable than

39:04

a four year degree in that

39:07

aspect Like I said, quality

39:11

lab work, I mean, many large breweries employ

39:13

people with PhDs to manage their yeast program

39:16

And so that's a very viable path

39:18

for someone from academia who wants to

39:20

go to work in industry to

39:23

be involved in beer Chris

39:25

White's PhD obviously, right? Right, exactly White

39:28

Land, yeah And

39:30

so if you're

39:32

super into microbiology and you want to get

39:35

into yeast and yeast health and fermentation and

39:37

quality and all of that, there

39:40

could definitely be some

39:42

real value to that bachelor's degree Or

39:45

a more traditional sort of bachelor's degree

39:47

and a more general biology

39:50

or chemistry focus is often just

39:52

as good because the beer

39:54

people figure, well, we can teach you about beer We

39:56

can teach you about yeast, you can learn about brewing

40:00

If you've got the lab background, that's really

40:02

valuable in that department. Sure. Well,

40:05

let's talk about payback. So a lot of people go into

40:07

debt to go to college these days. What

40:10

kind of return can you expect if you get,

40:12

say, a technical degree or maybe an associate's degree

40:14

from a program like yours in

40:16

terms of salary? Well, so

40:19

first, I want to talk about the cost of

40:22

the program. One of the

40:24

big advantages of where we are in a two-year

40:26

technical college is that the tuition is

40:28

really darn affordable. So

40:32

we're just over $200 per credit

40:35

at DCTC, which when

40:38

you do break it down per credit, that

40:40

means the flagship in-person program is right around

40:42

$5,000 for the full school year.

40:46

Yeah, I bet. And then

40:48

the online-only program has fewer credits because we

40:50

don't have that in-person lab component. We rely

40:52

on the internship for that. So

40:55

the online program is actually fewer credits. It's

40:57

actually under $4,000. So

41:00

right off the bat... So

41:02

you're not going to $200,000 in the debt for college. No.

41:06

This type of certificate is really

41:08

affordable. On top of that,

41:10

residents of Minnesota, you know, we're a

41:13

Minnesota-based college. We're part of

41:15

the Minnesota state system. Residents

41:17

of Minnesota who don't already have a

41:19

bachelor's degree could probably get their schooling

41:21

paid for entirely. Wow. That's the program

41:23

that Minnesota is launching. And so

41:26

that means if you live in Minnesota right now,

41:28

you could probably get free college. Don't already have

41:30

a bachelor's degree. It depends on how much money

41:32

you make. But if you're working in the beer

41:34

industry, I can tell you you're not going to

41:36

be above that threshold. Well,

41:38

that's the other side. How much do you actually make? So

41:41

is it a shift brewer or production brewer? Right.

41:44

And this has been trending upward in recent years, at

41:46

least where I am. So

41:48

to put some real numbers on

41:50

it, in Minnesota,

41:53

or at least in the metro area around Minneapolis,

41:56

St. Paul, which is where I'm most familiar, you

41:58

know, it's a pretty representative city. not

42:00

the most expensive place to live in the country, but

42:02

it's still a major city. It's got a higher cost

42:04

of living than some of the more rural parts of

42:06

the country. Kind of mill the road, kind of average

42:08

in terms of number of breweries and

42:11

opportunities and cost of living and all that.

42:13

So around where I'm at, I

42:15

don't really see, um, full-time

42:18

production staff anywhere making less than $20

42:20

an hour. Um,

42:24

and anyone who's got Brewer

42:26

in their title, it's probably making 22 or

42:29

more dollars an hour. Mm-hmm. And

42:33

you can look at salary ranges for

42:35

head brewers or, um, sort

42:38

of more, uh, higher up positions

42:40

in, in larger breweries being anywhere from 60

42:42

to a hundred thousand dollars a

42:44

year. Sure. Um, again, this is just

42:46

me. I don't have any data to back this up.

42:48

This is just sort of me taking the pulse of,

42:51

of, of the industry around me. Uh,

42:54

so, uh, I mean, it is

42:56

not the most high paid job in the world.

42:58

I mean, we all know that, um, but it

43:00

is at least around here, still a

43:03

living wage and, and there is room for growth.

43:05

And if you begin in the industry, you can

43:07

sort of right at the entry level, be supporting

43:09

yourself pretty decently. And that there is, there is

43:11

room to grow into, um, the

43:14

sort of full-time salary positions that, I

43:16

mean, that's what I was, you

43:19

know, living on for, for 10 years

43:21

before, before coming into education. I mean, I actually

43:23

took a pay cut to come into college

43:25

education. So that's sort of where we're at

43:28

in terms of the, in terms of industry.

43:31

Um, and compared to, like I

43:33

said, I don't know the cost of all the

43:35

other programs. I know what I paid, um, or

43:37

what the cost was of me to go to Siebel. It was

43:40

quite a bit higher. And, um,

43:42

compared to like a two year or

43:44

four year education. Uh,

43:46

I mean, the, the, the all in

43:48

bill for this certificate is, is pretty

43:50

darn affordable and it does allow you

43:52

to go. Directly from

43:55

this certificate into the

43:57

workforce in a brewery. I mean, even

44:00

a bachelor's degree at a regular four-year

44:03

college, a state school is what, over 20

44:05

grand now I think, right? I

44:08

mean, per year, I'm talking about. For a

44:10

year, right, yeah, exactly. So,

44:15

would there be much, you know, would you see a

44:17

much higher salary perhaps with a bachelor or master's degree?

44:19

I guess not as a

44:21

production brewer probably. No, probably not as a production

44:23

brewer, no. If you want to go

44:25

straight to a manager role or work

44:28

into a quality department, there's probably more

44:30

than 20 to 23 bucks an hour

44:33

in those departments, right? Sort of right with

44:35

a bachelor's. But

44:38

in production, I mean, not really. I mean,

44:40

we're an industry that is partially

44:43

based on passion. People

44:45

have a passion for beer, they like making the

44:47

product. And so, there is

44:49

usually someone

44:51

who is willing to do that job

44:54

for around that 20 to 20 some

44:57

dollars an hour mark. So, a

45:00

bachelor's degree doesn't necessarily set yourself ahead in

45:03

production. It might set yourself ahead if you

45:05

get that real production experience and then

45:07

want to move into a management

45:09

role like what I was doing. Yeah, or

45:11

maybe an entrepreneurial thing where you're actually interested

45:13

in opening your own business perhaps. Yeah,

45:16

exactly. Of course, that has its own costs. Well,

45:20

are there any aspects of the program that we didn't

45:22

cover already? Um,

45:25

you know, gosh, I don't think so. No,

45:28

I think we've really covered it. Oh, good.

45:30

You know, other than maybe the URL where

45:32

people can go to learn more. Yeah, sure.

45:34

Please, yeah, share. Where can people learn more?

45:37

I should have asked that. So, it

45:39

is Dakota County Technical College.

45:41

So, those letters are dctc.edu

45:44

slash brew. That's

45:48

B-R-E-W. I'll say

45:50

it again. dctc.edu/brew.

45:53

And that'll have all the information about the current

45:55

program and a little note there

45:57

that we are launching the new online program.

46:00

upcoming this year. Great. I'll

46:02

make sure if you send it a link I'd

46:04

be happy to put it on the show notes

46:06

for people can find out. beersmith.com/blog is where the

46:08

shows are listed and the show notes are for

46:10

all the episodes. Well awesome

46:13

Andrew I just want to get your closing thoughts now.

46:17

Well you know I have

46:20

been so focused on you

46:23

know the education aspect of

46:25

brewing and you know

46:27

recognizing that there is a need for skilled

46:30

qualified brewers in the industry.

46:34

That I am just

46:36

you know you might hear a lot

46:38

of mixed messages

46:40

about making

46:44

the transition from home brewing into pro

46:46

brewing or people

46:49

in the industry saying why would you ever

46:51

want to become a brewer and I can

46:53

tell you that I made that decision and

46:55

I enjoyed it. I

46:57

thought it was a wonderful decision. I wouldn't

47:00

have left the brewing industry for a

47:03

different job unless it was something like

47:05

what I'm doing and so I

47:08

guess my closing thoughts are that

47:13

it's still a good industry

47:15

to work in if you're passionate about

47:17

beer. There are good jobs out there

47:19

and that education

47:21

is a part

47:23

of the equation that hasn't traditionally been part

47:26

of brewing. You know it's often been an

47:28

on-the-job apprenticeship type type

47:30

industry but I see

47:33

that changing and I think that

47:36

if you're the type of person who is

47:39

contemplating that sort of a career change or

47:41

contemplating it in this industry that a low-risk

47:43

way to do it is to start with

47:45

education and find out is this you know

47:47

before you quit your day job is this

47:49

really for me. You know one of the

47:52

best ways to do it is with not

47:54

just not just this program here at DCTC

47:56

but any of the multiple sort of non-degree

47:58

certificate based just what

48:00

you need to learn type programs are

48:02

really a wonderful way to explore

48:04

if this if this industry is right for you because I

48:07

think it is right for a lot of people.

48:10

Awesome Andrew well really appreciate you coming on the show

48:13

today thank you so much for being here. Yeah

48:15

thanks for having me. My

48:17

guest today was Andrew Burns he's

48:19

instructor at Dakota County Technical College

48:22

and he's also a brewer. Andrew

48:24

thank you again really appreciate it. Thanks

48:27

a lot. A big

48:29

thank you to Andrew Burns for joining me this week.

48:32

Thanks also to our sponsors, Craft Beer

48:34

and Brewing Magazine. They invite you

48:36

to join their upcoming brewery workshop, March

48:38

24th to 27th in Austin, Texas.

48:41

This one of a kind event brings together professional

48:43

brewers to help you start or grow your own

48:46

craft brewery. To learn more

48:48

please visit brewery workshop.com again

48:50

that's brewery workshop.com

48:54

and also the barrel mill creators of

48:56

the infusion spiral used to add flavor

48:58

and aroma to wine spirits and beer.

49:00

Their unique spiral cut design creates unrivaled

49:03

surface area in a small package allowing

49:05

fast extraction of the toasted oak's

49:08

aroma and flavor compounds. Looking

49:10

for woods other than oak try their exotic

49:12

woods offering spirals made

49:14

from amberana, American and

49:16

French oak, aspen, Spanish cedar, cypress

49:19

and sugar maple. For

49:21

more information go to

49:23

infusion spiral.com again that's

49:25

infusion spiral.com And

49:28

Beersmith Web, the online version of Beersmith

49:30

Brewing Software. Beersmith for the

49:32

web lets you design great beer recipes from any

49:34

browser, including your tablet or phone. Edit

49:37

recipes on the go with access to the same

49:39

full suite of recipe building tools

49:41

as our desktop version. Try Beersmith for

49:43

the web today by creating a free account

49:45

at Beersmith recipes.com.

49:48

And finally to remind her to click

49:51

that click that like and subscribe button

49:53

on YouTube, iTunes, Spotify or whatever platform

49:55

form you're on. Clicking those buttons

49:57

is a great way to sport the show. I'd

50:00

like to thank you for listening and I hope you

50:02

have a great Brewing Week!

From The Podcast

BeerSmith Home and Beer Brewing Podcast

The BeerSmith Home Brewing Show is a beer brewing podcast focused on how to brew beer, homebrewing techniques, and beer stories from top US and international brewers. In each episode we bring you an interview with guests assembled from around the world to talk about beer, craft beer and homebrew. The BeerSmith podcast is hosted by Dr Brad Smith, the author of BeerSmith homebrewing software, the book Home Brewing with BeerSmith, and the BeerSmith blog which attracts over 200,000 readers monthly. Website: http://BeerSmith.com/blogJoin Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

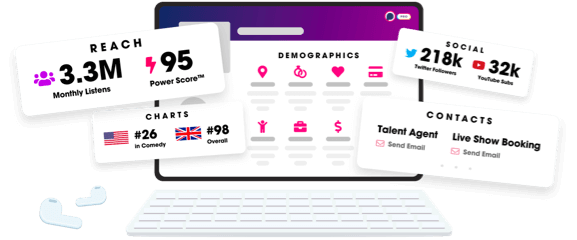

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us