Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:00

Hi, everyone. We've

0:00

set up this being an engineer

0:03

podcast as an industry knowledge

0:03

repository, if you will, we hope

0:08

it'll be a tool where engineers

0:08

can learn about and connect with

0:10

other companies, technologies,

0:10

people, resources and

0:13

opportunities. So make some

0:13

connections and enjoy the show.

0:18

And she was

0:18

cursed, most upset, and there

0:22

was no place in this small town

0:22

that you could get anything like

0:25

that repaired fact they had no

0:25

idea what they were. And so she

0:29

made the statement, and she

0:29

said, if someone could fix this,

0:35

I give them the best kiss they'd

0:35

ever had.

0:37

Hello, and welcome

0:37

to the being an engineer

0:54

Podcast. Today we're talking

0:54

with Stan Bentley, whose

0:58

background includes a mix of

0:58

electronic design and

1:01

manufacturing. Stan started

1:01

diversified systems in his

1:05

garage back in 1972. After

1:05

graduating with a W degree and

1:09

grit to nearly 700 people doing

1:09

electronic design, PCB

1:14

fabrication and assembly. In

1:14

2010. Stan started DIVSYS doing

1:20

similar activities, but without

1:20

the heavy manufacturing and

1:23

eventually sold that business in

1:23

2018. Recently, Stan started his

1:28

third company DIVaero.

1:28

Hopefully, I'm pronouncing that

1:31

correctly, focusing solely on

1:31

ITAR electronics. Stan, welcome

1:36

to the show. And thank you so

1:36

much for joining me today.

1:39

Well, thank you for having me.

1:41

All right. To get

1:41

things started off, I'm going to

1:44

throw you a softball question.

1:44

What made you decide to become

1:48

an engineer?

1:52

That may be less

1:52

less of a softball, the I

1:57

actually first got into

1:57

electronics, and then decided

2:02

that engineering was the way to

2:02

pursue electronics. And that's a

2:07

funny shaggy dog story that I

2:07

don't often tell but they, I was

2:13

in the seventh grade. And I grew

2:13

up in a rural area of

2:19

southeastern Kentucky and the

2:19

coalfields, the Appalachian

2:22

Mountains. And so as you can

2:22

imagine, we were pretty isolated

2:27

from about everything. And in

2:27

that time period, the first

2:31

transistor radios handheld

2:31

transistor radios came out. So

2:35

that's how far back I go in this

2:35

industry. And these early little

2:39

handheld devices were crude poor

2:39

am only. And it took a they

2:45

didn't even have a speaker that

2:45

first would you actually use the

2:48

little earphone earlier, but

2:48

they and the I had just started

2:56

to notice that girls were

2:56

different.

3:04

The what was the prettiest girl

3:04

in our class in school, I think

3:10

was also one of the wealthiest

3:10

had, she got one of these

3:16

transistor radios. And of

3:16

course, we all knew it, who did

3:19

odd about this thing. And so she

3:19

was in a group one day with this

3:23

passing the earphone around and

3:23

it stopped working. And she was

3:28

cursed, most upset. And there

3:28

was no place in this small town

3:32

that you could get anything like

3:32

that repaired fact, they had no

3:36

idea what they were. And so she

3:36

made the statement. And she

3:40

said, if someone could fix this,

3:40

I give them the best kiss they'd

3:45

ever.

3:48

That was all the motivation you needed.

3:51

No clue how this

3:51

thing worked or anything else.

3:56

But I thought this is something

3:56

I have to drive around and said,

4:03

I'll fix it.

4:06

And how did that turn out?

4:09

It actually

4:09

worked. I took this thing home.

4:11

And they turned out that I

4:11

didn't even know this. My father

4:16

was an electronics instructor

4:16

was an officer in the Navy. And

4:21

consequently in our base, there

4:21

were some things he had brought

4:24

back one of which was a

4:24

soldering iron. And he gave me a

4:28

quick crash course in this this

4:28

thing. So I was I started trying

4:32

to take this radio apart I

4:32

discovered that the A would

4:35

actually that the earphone the

4:35

plug piece had a poor solder

4:40

joint and it come loose and that

4:40

if I touch that wire back to the

4:46

solder connection, the thing

4:46

played and so I learned very

4:50

quickly how to solder did what

4:50

was probably today an incredibly

4:54

crude, crude job of soldering

4:54

that screwed it all back

4:59

together it all played. So I

4:59

took it back and true to her

5:03

word. I handed her the radio and

5:03

I got my my first real kiss.

5:12

That's a wonderful

5:12

story. Thank you for sharing

5:14

that. Well, you started your

5:14

career as a designer and

5:20

eventually moved into

5:20

manufacturing what what

5:22

motivated you to make that

5:22

change?

5:25

Well, actually, it

5:25

really started in college, the I

5:30

was in graduate school, the

5:30

program that I was part of was

5:35

really funded through a NASA

5:35

grant that ultimately routed to

5:39

us. And in that we were building

5:39

a remotely piloted vehicle,

5:46

which was kind of interesting.

5:46

And it was really intended for

5:51

sending into hazardous

5:51

environments, particularly since

5:54

this was Kentucky, coal mining

5:54

accidents. And as part of that

5:59

design effort, we needed printed

5:59

circuit boards, and there would

6:05

go back to the 19 6970

6:05

timeframe, there was no way to

6:09

buy those. And so basically, I

6:09

had to figure out how to crudely

6:14

make PCBs and kitty litter pans,

6:14

so that we could create the

6:21

designs or implement the designs

6:21

we were working on. So I carried

6:25

that forward. When I left school

6:25

as a design engineer, had the

6:28

same problem again, I needed

6:28

PCBs, and couldn't buy onesie

6:33

twosie. And so I created another

6:33

small lab, making little more

6:37

sophisticated ones, because we

6:37

had a little more money, and

6:40

very quickly decided that would

6:40

be a business. And so I formed a

6:46

company in 72, to design

6:46

microprocessor based things and

6:52

make crude PCBs.

6:54

Now, the company

6:54

you were working at before you

6:57

started your own business, was

6:57

that Randsburg?

7:00

That's correct.

7:00

They are Randsburg is an

7:03

interesting company, that name

7:03

is still around the company and

7:08

what they did lives on. They the

7:08

person who started that company

7:13

was a gentleman by the name of

7:13

Harold Greensburg, and who's

7:16

kind of a unique sort of

7:16

inventor even though he did not

7:19

have a technical background. And

7:19

what he did was he invented the

7:25

electrostatic painting process.

7:25

And by which everything today is

7:31

painted or powder coated, powder

7:31

coating, yeah, okay. And so that

7:36

process came out of this company

7:36

also. Amazing. So that was

7:41

really what was an interesting

7:41

story. I was really hired out of

7:45

graduate school, I had no

7:45

intention of I thought I would

7:48

stay to become a professor

7:48

because the life on the college

7:52

campus for a young guys not too

7:52

shabby. But this company, since

8:01

they had invented the process,

8:01

at the same time, the EPA was

8:05

created in this seven days, and

8:05

one of the very first industries

8:10

they they went after was the

8:10

really the automobile industry,

8:14

but more specifically painting.

8:14

Because anyone that was around

8:19

in that era, and that lived, for

8:19

example, let's say in Detroit,

8:24

you literally could walk across

8:24

the Detroit River. The paint

8:28

film on it was unbelievable, in

8:28

fact that the river in

8:31

Cleveland, Ohio, caught fire and

8:31

burned. And so the EPA was

8:38

looked was looking at the

8:38

painting industry, because they

8:40

were just the bottle tool was

8:40

just going up the stacks into

8:44

the air and the overspray was

8:44

just being dumped. I know that

8:49

today that seems like an

8:49

impossible thing. But this was

8:53

the situation and in 19 6970

8:53

timeframe. And so consequently,

9:00

a hand spray operation for

9:00

anyone that's ever used a spray

9:03

can and you know that most of it

9:03

goes everywhere, but where you

9:05

aimed it. And that's pretty much

9:05

the that was the case with the

9:09

painting industry. So for

9:09

example, an automobile, that

9:13

vintage had roughly a gallon of

9:13

fit of paint on it when they

9:18

left the factory, but they

9:18

sprayed five to get one on

9:22

there. That's staggering.

9:22

Unbelievable. The transfer

9:25

efficiencies were in the 25%

9:25

range. And so consequently, you

9:31

can see why they were producing

9:31

in this was the heyday of the

9:37

auto industry, about one car a

9:37

minute came off of those lines.

9:41

So it doesn't take too much like

9:41

too much. Math says look, if you

9:45

go to Ford, GM, Chrysler and so

9:45

on, you get a lot of paint film.

9:51

Well, the the crudest

9:51

electrostatic process would

9:55

generate almost 90% Or a little

9:55

better than 90% trends. We're

10:00

efficiency, we later huge, huge,

10:00

we got those numbers up to 95,

10:04

or 96. But the problem was, they

10:04

did this by charging the paint

10:10

to 100,000 volts DC. And so if

10:10

if you've ever had, most people

10:17

haven't had an electrostatic

10:17

Spark, you've got essentially a

10:21

charged atomizing device, that's

10:21

at 100,000 volts and you have a

10:25

grounded metal object. You don't

10:25

have to get too close before you

10:30

draw a lightning bolt. And if

10:30

you do that in a carburized

10:34

mixture of solvent and air, you

10:34

get a fire. So one hand we could

10:39

solve the EPA problem, but on

10:39

the other, we could burn a

10:43

factory. And so that was

10:43

essentially the the challenge

10:48

that I was given. And that's

10:48

what drew me out of graduate

10:52

school, instead of being a

10:52

professor was figuring out how

10:54

to make one of these things safe.

10:56

Interesting, well,

10:56

fun project for your first real

10:59

project out of school

11:01

big, I had no clue

11:01

how to do it.

11:05

Well, I think

11:05

this, what I read on your

11:10

LinkedIn pages talking about

11:10

this very time, you said that

11:15

having unlimited resources, and

11:15

being surrounded by incredibly

11:18

talented and motivated people,

11:18

is something few engineers ever

11:22

experience, yet you did

11:22

experience and that it built the

11:26

foundation for all of your

11:26

engineering accomplishments for

11:29

the next 40 years. Can you talk

11:29

a little bit about about that

11:33

time and you share, you know,

11:33

what you were able to learn and

11:36

accomplish with unlimited

11:36

resources and talented motivated

11:40

people.

11:41

But both of those

11:41

are a blessing that few

11:44

engineers really get,

11:44

particularly to have both. And

11:49

at that age, especially your

11:49

age, correct. And the this was

11:54

really the result of trying to

11:54

solve the problem of how to make

11:59

electrostatic systems safe. And

11:59

so the company was sitting here

12:04

faced with an opportunity that

12:04

was just unbelievable, if they

12:07

could solve this, this problem.

12:07

And they were very cash rich,

12:12

even though they were small,

12:12

they were a cash rich company,

12:15

because they had made very good

12:15

margins on the things they did.

12:21

And so consequently, they really

12:21

had a very short period to solve

12:25

it. And essentially, it said,

12:25

Just spend whatever you need to

12:29

spend and hire whomever you need

12:29

to hire. And so that allowed me

12:34

to relate to hire the cream of

12:34

the crop of the young tech

12:38

talent. And I did the same

12:38

thing. So it's no one knew how

12:42

to do this. There was no reason

12:42

to go look for experience, I

12:45

looked for smarts. And we had

12:45

the cash to experiment with this

12:51

to brainstorm the ideas. And

12:51

with that, it really taught me a

12:56

whole batch of things. One, I

12:56

got to dabble in a lot of

13:01

different industries, which

13:01

again, sadly, a lot of engineers

13:05

don't, we seem to get

13:05

pigeonholed. And we spend all of

13:09

our career doing something

13:09

that's a mile deep and an inch

13:12

wide. And in this particular

13:12

case, I had the opportunity to

13:17

look across a lot of

13:17

disciplines, and to work with

13:21

smart people in all of those

13:21

disciplines. And so we did in a

13:25

period of about two years, we

13:25

solved the problem, we came up

13:29

with systems that worked. And

13:29

basically the entire painting

13:35

industry adopted this technology

13:35

globally. And so that was to me

13:41

was was just an incredible

13:41

opportunity. And with that

13:45

that's what I leverage then for

13:45

the next 40 years of my career

13:49

was the the lesson learned was

13:49

surround yourself with the

13:53

smartest people you can find no

13:53

ideas, a bad idea. And sometimes

13:59

the most off the wall things are

13:59

the things that really can

14:03

develop into world class

14:03

products.

14:06

I can get a sense

14:06

of how seeing that actually work

14:13

would give you an incredible

14:13

amount of confidence that maybe

14:16

you wouldn't have otherwise. I

14:16

remember working on a project

14:20

several years back and it was

14:20

with an inventor. And he was not

14:25

an engineer, but he was a bright

14:25

guy. And we had tried a variety

14:29

of different things. Two, it was

14:29

a very mechanical solution here.

14:33

And none of them had really

14:33

worked and he came up with this

14:36

idea that was just so far out

14:36

there. And I thought there's no

14:38

way that's going to work. This

14:38

is crazy. You know, I'm the

14:41

engineer here this is not going

14:41

to work. What are we wasting our

14:44

time on this for? And lo and

14:44

behold, it worked. It was the

14:47

one that worked you know, it was

14:47

just this out there crazy idea.

14:51

And and it worked and and that

14:51

was just you know a relatively

14:55

small thing here you are one of

14:55

the pioneers of powder coating

14:58

for Good grief. You know A major

14:58

manufacturing process that's

15:01

used by WHO KNOWS hundreds of

15:01

1000s Millions of processes to

15:07

this date and having a success

15:07

like that I'm sure you were able

15:11

to ride on that experience for

15:11

Well, like you said, the next 40

15:15

years of your career?

15:17

That's correct. I,

15:17

the irony of it was that I

15:21

really didn't stay in that

15:21

industry. Once I formed my own

15:25

company, then it was really just

15:25

a variety of industries. Because

15:30

what we specialized in was

15:30

people would walk in with a

15:35

problem, yes, we made stuff, we

15:35

made printed circuit boards, we,

15:38

we put parts on boards, we

15:38

created product, but what we

15:42

really specialized in was

15:42

bringing in something that

15:46

wasn't working quite correctly

15:46

or didn't work at all. And

15:50

figuring out how to either in

15:50

some cases, just manufacture it

15:54

in other cases, fix it such that

15:54

it did the perform the

15:59

application that the inventor if

15:59

you will intended. So we weren't

16:04

really coming up with these

16:04

creative ideas as much as we

16:07

were helping someone win that

16:07

spark, figure out how to

16:11

implement it, and make the whole

16:11

thing work. And that is really

16:16

to me, what has been the fun of

16:16

an entire career is that you

16:19

don't know where the next

16:19

application is coming from. It

16:22

could be any field you can

16:22

imagine.

16:25

Yeah. Oh, how

16:25

great just solving fun, hard

16:28

problems. I mean, is there

16:28

anything better for an engineer

16:31

to do? That's really why we're here?

16:34

I don't think so.

16:34

All right. Well, every day.

16:39

Absolutely. Yep.

16:39

You started your first company,

16:43

diversified Systems, Inc, in

16:43

your garage, and eventually grew

16:48

to nearly 700 people what walked

16:48

us through that journey? What

16:53

How did that happen?

16:54

Well, the I for

16:54

really, for some time, I wanted

16:59

to actually start a company,

16:59

even as far back as the college

17:04

days. And so I by total chance,

17:04

met a an individual in a bar.

17:12

And he was the term that was the

17:12

chief engineer of a company. And

17:20

this company made, they

17:20

invented, I believe I'm correct

17:26

in this. I know, they made the

17:26

very first ones. And I think

17:29

they came up with the idea, the

17:29

first dollar bill changers. And

17:34

so he's sitting in basically

17:34

his, they created this, they put

17:39

them out on the market. And the

17:39

problem was, and the reason he

17:43

was in the bar drinking was that

17:43

someone had discovered with

17:48

these early dollar bill

17:48

changers, if they folded the

17:51

dollar bill in half and toric,

17:51

they could feed both halves into

17:55

the machine and get $2 and

17:55

change. And this was before the

18:02

internet, of course, by a long

18:02

shot, but it's amazing, just how

18:06

well the communication channels

18:06

were.

18:12

I believe it.

18:14

And so

18:14

consequently, what he was

18:16

looking for was someone to solve

18:16

that problem very quickly, and

18:22

make lots and lots of these

18:22

because they had 1000s of these

18:26

things. had been I'm assuming

18:26

1000s I know we made 1000s of

18:31

the fix. And so that's what I

18:31

said, Well, I think we can

18:35

figure this out. And so that's

18:35

literally what we did in the

18:38

garage was designed a very

18:38

simple little circuit to fix

18:42

this, and then made a whole

18:42

batch of that we needed to make

18:46

the circuit boards. So I lined

18:46

up a batch of much as I've done

18:51

in college, I can't let her

18:51

pants because the very first

18:56

polyol of our polyethylene

18:56

containers had come out

19:00

Rubbermaid had just hit the

19:00

market. And polyethylene works

19:04

out to be a fantastic thing for

19:04

chemicals. So the cheapest

19:08

polyethylene tanks I could buy

19:08

were at the pet store. And so I

19:12

gave you a letter payments, and

19:12

basically set up a line to make

19:18

the PCBs and then on a workbench

19:18

in my garage, I think corral

19:23

neighborhood help and my wife

19:23

and so on, and we taught them

19:28

how to solder and we soldered

19:28

these and we made 1000s of them

19:31

and ship them to actually hand

19:31

delivered them to this company.

19:36

And they installed these

19:36

everywhere into their dollar

19:40

bill machines to so that you $1

19:40

gave you $1 change.

19:44

That's awesome.

19:44

And how old were you at this

19:46

point? 2424 That must have been

19:46

so fun. I mean just working out

19:52

of your garage and you don't

19:52

have a big staff right your is

19:55

you and your wife and whoever

19:55

from the neighborhood you can

19:58

pull in and just make this

19:58

happen. What a great time that

20:01

must have been.

20:02

It was a whole lot

20:02

of fun. And so then we received

20:06

just word of mouth for extra,

20:06

because we knew nothing about

20:10

marketing sales or any of these

20:10

kinds of things. But there were,

20:15

it turns out a lot of companies

20:15

that had need of something like

20:19

that either PCBs or assembly.

20:19

And so very quickly, we needed

20:25

to, we needed more space. And so

20:25

we rented a small space and a an

20:32

office warehouse complex. But we

20:32

also needed equipment. And being

20:38

very, very new in the career and

20:38

not coming from wealth. There

20:41

was, there was no financing. And

20:41

so we needed money to buy the

20:47

stuff. And so we had a cute

20:47

little, kind of little off, it

20:53

was 1200 square feet, so it's

20:53

tiny. And so I started, I said,

20:59

Well, you need money, you go to

20:59

banks, I thought, I didn't know

21:03

that investors and venture

21:03

capital and all of these things

21:07

that you learned later in life.

21:07

So I started going to banks, and

21:11

with this idea of I needed to

21:11

borrow money. And it wasn't a

21:15

huge amount, but it was maybe

21:15

two or $300,000, which in 1973,

21:21

four timeframe was was a lot of

21:21

money. And so I went to the

21:28

major banks in town, and was

21:28

unceremoniously thrown out of

21:32

every one of them. Not even

21:32

nicely. And so I actually went

21:40

into a small town bank, and I

21:40

walked in, and um, you know,

21:44

I've gotten the big banks are

21:44

not going to work. And as I

21:47

walked in, off to my left, I saw

21:47

an office with a guy sitting

21:52

there and know that the placard

21:52

on the door, said, President, so

21:57

I said, Well, if I go to the

21:57

receptionist and asked to see

22:01

him, I know how that works. So I

22:01

just walked straight in his

22:04

office and sat down, said Hi

22:04

there. And Tony, what I wanted

22:10

to do. And he said, Well, I'll

22:10

tell you what he said. We're,

22:16

I'm intrigued about the

22:16

possibility of maybe investing

22:19

in a small company. Why don't I

22:19

bring some of our board members

22:24

and so on, and come see your

22:24

little company? Well, that's a

22:28

great idea, except there wasn't

22:28

much to see

22:31

the garage.

22:33

Well, we, yes,

22:33

everything was in the garage, we

22:36

had this this little this nice

22:36

space. So I go back and think

22:42

about this. How do we do a tour

22:42

fortunately, it was going to be

22:45

a week or so before they come.

22:45

So what I did, I went to all of

22:50

the neighbors, whose wives and

22:50

other folks had been kind of

22:53

coming in and helping solder

22:53

stuff. And we borrowed all kinds

22:58

of things from work tables, work

22:58

benches, we borrowed curtains,

23:03

we borrowed chairs, and decorate

23:03

this space. So it had a little

23:07

entry office area with a little

23:07

tiny desk. And then it opened

23:11

into this. Well, that would be

23:11

about 1000 square foot, kind of

23:17

just block wall factory. And we

23:17

set all of that up with

23:21

workbenches. And then we took a

23:21

set of parts because I didn't

23:26

have enough parts that we could

23:26

actually show a line running and

23:29

we have no employees. So on the

23:29

day that the tour was supposed

23:33

to happen, then the ladies of

23:33

the neighborhood, I don't

23:38

remember now how many it seems

23:38

like there was a lot but it

23:40

probably was maybe six or eight.

23:40

They got there early, and we set

23:45

up an assembly line. And so what

23:45

we would do, since we only had

23:49

one set of parts, these were

23:49

through hole in that that era.

23:53

So they would one group was

23:53

sitting there, they would put

23:58

the parts in the PCBs and then

23:58

they would pass them and each

24:00

person would add parts and so

24:00

on. They get to an inspector at

24:04

the end of the line when we

24:04

didn't solder them. So the

24:06

person at the end of the line

24:06

then was taking the parts back

24:09

out and putting them in advance

24:09

to the front of out of my world

24:25

basically this little factory,

24:30

and they bought it

24:30

they had no idea.

24:34

I don't even

24:34

remember how much but I think

24:37

around $100,000 Just on a

24:37

signature and no personal

24:42

guarantees none of the stuff

24:42

that I learned a whole lot about

24:45

later in life. And so we then

24:45

bought the equipment we actually

24:50

needed that on a more efficient

24:50

basis make PCBs and to assemble

24:59

this amazing I just kind of

24:59

built from there.

25:03

What a fantastic

25:03

story. Wow, that's one of the

25:05

better ones that I've heard.

25:05

Well, let's see, this is

25:11

probably a good good time to

25:11

take a short pause and share

25:14

with the listeners that Team

25:14

pipeline.us is where you can

25:18

learn more about how we help

25:18

medical device and other product

25:21

engineering or manufacturing

25:21

teams develop turnkey equipment,

25:25

custom fixtures and automated

25:25

machines to characterize,

25:28

inspect, assemble, manufacture,

25:28

and perform verification testing

25:32

on your devices. And we're

25:32

speaking with Stan Bentley today

25:36

who just has some really

25:36

wonderful stories. Going back to

25:41

DSI diversified systems, you had

25:41

written a little bit about the

25:46

culture there and back in that

25:46

day, correct me if I'm wrong,

25:50

but culture at a company was not

25:50

the buzzword that it is today.

25:54

Yet, it seems that you were very

25:54

proud of the culture that you

25:57

develop there. You talked about

25:57

a child daycare with

26:00

kindergarten, a variety of

26:00

educational courses, a 25 acre

26:05

beautiful campus, a Wellness

26:05

Center, and more. What What

26:09

effect did that culture have on

26:09

the daily lives of the people

26:13

who work there?

26:14

Well, it's, you

26:14

know, when you look back on all

26:18

of those things, and of course,

26:18

today, this is very much in

26:20

vogue. But if you look back on

26:20

it, I'd like to say that this

26:24

was a brilliant strategy that we

26:24

thought out. But the reality

26:29

was, these were things that

26:29

happened kind of incrementally

26:32

that worked very well, and all

26:32

of a sudden became well, gee,

26:36

that's obvious, why wouldn't you

26:36

do this, but they start with the

26:42

the campus itself, we we grew

26:42

very quickly during the 80s. And

26:47

we made very, very good money

26:47

because we could make printed

26:50

circuit boards that plated

26:50

through hole of multilayer when

26:53

very, very few shops in the USA,

26:53

other than huge mega shops could

26:58

do so. So we actually, which is

26:58

one of the interesting stories

27:03

that building a 25 acre campus,

27:03

actually was the building where

27:07

I first started to work for

27:07

Rensburg corporation. So in the

27:12

the early 90s, I actually

27:12

purchased the facility and the

27:17

land from the company where I

27:17

really started to work. And we

27:23

spent a year renovating that,

27:23

that building, and we just

27:27

gutted it and put everything

27:27

back back new. But then when we

27:32

get to the late 90s, as the

27:32

company is really, really

27:35

growing very rapidly, people

27:35

became a product, very much like

27:40

the situation exactly the

27:40

situation today, where you

27:44

literally cannot get the people

27:44

that you need, particularly if

27:50

you're looking at these early

27:50

employment, early young

27:55

professionals and so on. And my

27:55

wife actually came to me. And

28:01

she said, you know, you're

28:01

trying to hire these folks.

28:04

There's all kinds of reasons

28:04

why, you know, they can't come

28:07

to work and so on. And what you

28:07

want are these young

28:10

professionals, she said, if we

28:10

would create a daycare, then you

28:16

would be able to pull out of

28:16

pull into the market people that

28:22

for various childcare reasons,

28:22

can't come into the market. And

28:27

so I thought, let's give this a

28:27

try. And it turns out the

28:31

building happened to have about

28:31

a 12,000 square foot executive

28:36

office complex attached to it

28:36

through a breezeway that we

28:40

never occupied because the

28:40

offices were to swipe. As I told

28:47

all of my managers who all

28:47

coveted one of these because

28:50

they all had private bathrooms.

28:50

I said, you know, if customers

28:54

come to see us, and we're in

28:54

these kinds of digs, first thing

28:58

they're going to assume is

28:58

they're paying us too much. So

29:02

we never occupied this. And so

29:02

we went in and just renovated

29:06

this space, which wasn't

29:06

difficult, because it was a

29:09

series of large offices, and had

29:09

a huge open area in the middle.

29:13

And we just took out the adult

29:13

toilets and put in kids toilets,

29:21

types of things. And we then

29:21

struck a deal actually with

29:25

Easterseals to manage this

29:25

facility for us because we knew

29:29

nothing about managing a

29:29

daycare. There's all kinds of

29:32

permits and and some horror

29:32

stories going around there was

29:38

again, people of that era would

29:38

remember there was like I think

29:41

it was the Mary Martin preschool

29:41

where they had all kinds of

29:45

child abuse things that happen.

29:45

Allegedly, I'm not sure how I

29:50

will that came out. But anyway,

29:50

what we did is we we've struck a

29:55

deal with Easterseals to manage

29:55

this facility and hire the staff

29:59

and and it filled up instantly.

29:59

It held 126 kids in a stateful.

30:06

And we took them all the way

30:06

from basically newborns through

30:10

and it could do kit was a

30:10

teaching facility, so it could

30:14

do the kindergarten, so they

30:14

were ready for them to go on to

30:16

school. And with that, suddenly,

30:16

we were just blessed with just a

30:21

flood of these young educated

30:21

professionals, men and women,

30:26

who were for various reasons

30:26

struggling with childcare. And

30:30

so now they had it on site. And

30:30

we had our just pick of whomever

30:36

we wished. And it just the

30:36

company grew like crazy with all

30:40

of this smart, you know, talent

30:40

just I can't even describe it.

30:47

Plus, it made you feel good. One

30:47

cute story in that one of the,

30:52

the older ladies in the factory

30:52

on the assembly area, it came to

30:55

me one day. And I'll tell you a

30:55

second story about her. But it

30:59

was interesting. And she said,

30:59

Hey, would it be okay? And she

31:05

said, there's a lot of us that

31:05

are, you know, for kids are

31:07

grown, we're either getting

31:07

grandkids, or we have no

31:10

grandkids or whatever? Would it

31:10

be okay, if if we went up some

31:16

time and maybe sat down and read

31:16

a story to the kids,

31:19

oh,

31:22

I can't really see

31:22

how that could be a problem. So

31:26

that we had this large open area

31:26

in the center. So we purchased

31:30

rocking chairs, and we put in

31:30

that open area. And that

31:34

immediately this became a hit.

31:34

And it was just men and women.

31:38

In fact, I go up sometimes he's

31:38

just sitting on the floor and

31:44

but these, these ladies would go

31:44

up and sit in the rocking chair.

31:49

And they started to call it a

31:49

rocker baby program. So they

31:53

will just assess the staff with

31:53

with the kids. And of course,

31:57

you know, the moms and dads

31:57

could go have lunch with him or

32:00

go see him whenever. And this

32:00

thing just worked. It was just a

32:03

tremendous employee benefit. And

32:03

other things then grew out of

32:08

that that we talked about. We

32:08

put in a cafeteria. And so with

32:13

the actual chef and the because

32:13

we eventually we were running

32:20

three shifts. So we really were

32:20

only closed Sunday mornings,

32:25

until really about one to 1pm.

32:25

And so fast food and so on

32:32

starts to get old, really pretty

32:32

quick. And it's availability on

32:36

the off hours as well, the

32:36

places that are open those hours

32:41

usually sort of stuff that at

32:41

least I associate with three in

32:46

the morning when the bar closed,

32:48

right, yeah.

32:51

So they that that

32:51

became a huge benefit. The

32:54

cafeteria actually started to

32:54

package meals that people could

32:58

order just at their desk, and

32:58

then they could go pick up these

33:03

packaged meals and take home

33:03

with them for the family. And so

33:07

that turned into a huge benefit.

33:07

Then my wife came to me with

33:11

another idea. prior life she was

33:11

a nurse before we turned her

33:16

into a production person and

33:16

running purchasing. But she

33:22

retired briefly because we now

33:22

had enough folks that she didn't

33:27

need to do these things. And she

33:27

said what we need is a is a

33:32

wellness program because you're

33:32

feeding them to well. So we

33:41

actually first put in a wellness

33:41

center with a really nice like

33:46

Nautilus kind of equipment and

33:46

so on. So we had all of the

33:49

treadmills and ellipticals and

33:49

and these kinds of things, then

33:54

we follow that very quickly by

33:54

opening a nurse's office that

33:57

she ran and where we then could

33:57

do routine kinds of things for

34:04

the employee blood pressure,

34:04

blood pressure checks and

34:07

cholesterol and someone is ill

34:07

do you really need to go see a

34:11

doctor you know dispensing

34:11

nomads or anything like this

34:14

just doing really very routine

34:14

care. And that turned into then

34:20

something that was a huge

34:20

Employee Benefit also.

34:25

You guys were like

34:25

Google before Google existed. I

34:28

mean, you just had this huge

34:28

campus this ecosystem of all

34:31

these perks and benefits it

34:31

sounds incredible. Was that very

34:36

rare back then or were there a

34:36

lot of companies doing these

34:40

sorts of things AI or anything

34:40

like that?

34:42

It was pretty

34:42

rare. I'm I am not I'm not

34:47

aware. I'm sure other people

34:47

did. Or certainly did pieces of

34:51

that. I don't know of anyone in

34:51

our geographic area. Yeah, that

34:55

had all of those. Today care

34:55

particularly that Was that one

35:00

was perhaps the most unique of

35:00

all of them. But it's great to

35:04

know. And you know, and it

35:04

really because we had the space

35:09

and we were fortunate in

35:09

striking a deal with

35:12

professionals to run this, that

35:12

it was just an incredible

35:15

employee benefit. And we allowed

35:15

the neighborhood to use it also

35:19

because we didn't fill up 126

35:19

kids, but by allowing the

35:26

neighborhood to fill the open

35:26

spots and always stay full.

35:29

Well, of course, they made an

35:29

incredible space outside we set

35:33

up play yard for each age group,

35:33

because we had it was like a

35:36

campus out their own their own

35:36

play yard.

35:42

Yeah. Wow, what a

35:42

fun mix of professional and

35:46

play.

35:48

Yes, there was

35:48

one, one quick story on the lady

35:53

that came to me about the rocket

35:53

before it was rocket baby. This

35:58

lady now currently, I'm the

35:58

North American technical

36:02

director, also, at least for the

36:02

next year, ICAPE corporation to

36:06

whom we sold the divsys

36:06

operation, and then opened the

36:10

military group. But so we have

36:10

in this facility assembly and

36:16

and essentially PCB sales. Well,

36:16

people are a big problem. But a

36:22

lady called me, oh, maybe four

36:22

or five months ago. And she

36:28

said, Hey, I've retired and I

36:28

work for you for a lot of years.

36:33

And I need something to do

36:33

because I'm going crazy. Well,

36:37

that's cool is you know, I mean,

36:37

if your eyesight is still good,

36:41

and your hand eye coordination

36:41

is good. So she came in for an

36:46

interview. And we hired her.

36:46

Well, this lady about a month

36:50

ago had her 87th birthday

36:53

at seven. Oh my

36:53

goodness.

36:57

And I just think

36:57

no one wants your

37:00

money. Oh, yeah.

37:01

Wow. Seven saying

37:01

I am bored. Goodness,

37:06

I hope I can use

37:06

the bathroom myself and 87 Much

37:09

less PCB.

37:12

Yeah, imagine

37:12

doing some more. eye sight is

37:16

good, or poor. it's just

37:16

amazing.

37:19

That's a good

37:19

stock there. Wow. Well, I'm

37:23

gonna bring this back towards

37:23

the technical end of things for

37:27

for this last one or two

37:27

questions. What are some of the

37:30

biggest challenges implementing

37:30

electronic designs into

37:35

products?

37:37

There's a while.

37:37

Number one is I think Mac I was

37:44

blessed in my early career, that

37:44

in the USA, really the PCB

37:49

industry pretty much was created

37:49

here. And so we could design

37:56

products. And we could either

37:56

make the PCBs ourselves are with

38:01

a very short travel distance,

38:01

don't see them being made. The

38:06

same was true on putting the

38:06

parts on the boards and

38:08

assembling. So consequently, as

38:08

design engineers, we had the

38:12

benefit of seeing how the

38:12

product was, was being made. And

38:17

working very closely with the

38:17

engineers that were doing those

38:20

particular processes, which

38:20

helped us to create really,

38:24

really good designs, very

38:24

manufacturable designs, however,

38:28

now is the protector, the USA,

38:28

the PCB industry is virtually

38:33

gone from here. And to a large

38:33

extent, the assembly of those

38:38

boards as well, I won't mention

38:38

assembly is making a healthy

38:42

return. But if we take the

38:42

situation as of today, so if

38:46

you're a young design engineer,

38:46

you're not one of the old salts

38:49

that had this benefit. You're

38:49

coming out of school, you've got

38:52

all these computer skills, you

38:52

know how to run simulations, you

38:56

know how to do all of these

38:56

things, that you don't know how

38:59

to make anything. And so you're

38:59

creating designs in a vacuum

39:04

based upon what you see on a

39:04

tube and algorithms that someone

39:08

wrote for you, and parts that

39:08

were made and stored in the

39:12

library and so on. And as a

39:12

consequence of that, your first

39:17

design probably ain't gonna

39:17

work. And if it does, it's

39:23

probably not going to be

39:23

something that's cost effective

39:25

to manufacture. And so I think

39:25

one of the biggest hurdles today

39:30

is how to bridge this gap.

39:30

Because we got all of these

39:33

bright young engineers coming

39:33

out, they've got these

39:36

phenomenal skills. They have

39:36

these creative ideas, but

39:41

eventually you have to make

39:41

stuff. And unless you want to be

39:45

if it's just software. And so

39:45

that's what I see is that the

39:50

benefit that myself and my

39:50

generation had as engineers,

39:55

these these younger engineers

39:55

don't have that. And we have to

39:59

figure out How to give them that

39:59

experience back. And that's

40:03

really a lot of what I'm trying

40:03

to do and the company that that

40:07

I work for now. But I think

40:07

everybody's struggling with this

40:12

because my day all day, every

40:12

day today is spent talking to

40:16

people about how do you how do

40:16

you make this? How do you turn

40:20

this into something real? And

40:20

that I think if we can fix that

40:25

problem, it's going to be pretty

40:25

phenomenal. But all of these

40:29

creative kids can do.

40:30

Yeah. Amen to

40:30

that. Kids. Yeah. Okay. Well,

40:36

Stan, this has been really a

40:36

delight speaking with you. Thank

40:39

you again for for sharing some

40:39

of your time today. How can

40:43

people get in touch with you?

40:44

Well, very easy.

40:44

One, I do have a LinkedIn page.

40:48

And I will confess that I don't

40:48

go there often. But if they send

40:53

an email through that, I get it.

40:53

But also my email is pretty

40:57

simple. It is Stan stan dot

40:57

Bentley spell Be en t le y. And

41:04

then that is at Dave arrow,

41:04

which is spelled di vaero.com.

41:14

And I respond to I get lots of

41:14

emails every day and I try to

41:19

respond to every single one of them,

41:21

as evidenced by

41:21

the 87 year old woman who's now

41:24

working for you again.

41:27

I think it's a

41:27

great human interest story. I

41:30

hope all of us can make it that far.

41:32

Oh, absolutely.

41:32

Yeah. All right, Stan. Well,

41:35

again, thank you so much. I

41:35

really appreciate you talking

41:38

with me today.

41:40

You're very welcome. I've enjoyed it.

41:45

I'm Aaron Moncur,

41:45

founder of pipeline design, and

41:49

engineering. If you liked what

41:49

you heard today, please share

41:52

the episode. To learn how your

41:52

team can leverage our team's

41:55

expertise developing turnkey

41:55

equipment, custom fixtures and

41:59

automated machines and with

41:59

product design, visit us at Team

42:03

pipeline.us Thanks for listening

From The Podcast

Being an Engineer

The Being An Engineer podcast is a central repository in which we collect and share industry knowledge & best practices associated with the discipline of engineering. We hope that engineers throughout the world will benefit from this content as they connect with the companies, technologies, people, resources, and opportunities that are relevant to their engineering or engineering-adjacent roles. Contact us at [email protected]. Intro and Outro music by John MartellJoin Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

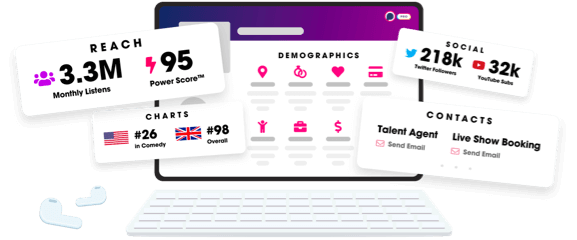

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us