We spend a lot of time on the podcast talking about the different roles of PLCs and the various types of equipment they are in. We cover how to manage PLCs you may have, what the future for PLCs looks like, What is a PLC, the PLC industry as a whole and how does someone get properly trained on PLCs?

The wildest part to me about speaking with Don is how many PLCs I had been using and wasn't even aware!

Don has a passion for the industry and having been brought up in the early days of Toyotas "lean & green principles" has a true appreciation for learning and development.

There’s so much in this conversation with Don, and I’m really excited to share it with you. We talk about how you can learn about PLCs, the benefits of PLC training and development, and so much more. I’m so thankful to Don for sharing this conversation with me. Enjoy!

Nicholas

www.bosspitality.com

More advice from Don on PLCs…

REF:

- PLC Learning Path

- Training Methods comparison chart

- What is a PLC video

- What is a PAC video

- PLC Programming Best Practices

- Using PLC Troubleshooting CNC example

- Troubleshooting PLC itself

- Managing your PLCs and Automation (+ free PLC audit spreadsheet)

- Industry 4.0 in USA: Risk (IIoT)

- PLC Control Panel Design for Maintenance

- Cyber Security - PLC Network to SCADA HMI to HTML5 or Smartphone

Summary of Podcast …

Learning PLC:

What is the recommended learning path PLCs and related automation control?

- Industrial Electrical

- Electrical Troubleshooting

- PLC

- PLC Troubleshooting

- HMI

- PAC

- Structured Text programming

- Oil process industry

- Field/Industry Specific

- SCADA

- Fieldbus

iii. PID

- Manufacturing industry

- Robotics

- Devicenet or other communication protocol

- Ancillary Topics

-

- Computer classes

- Cyber awareness

- Networking

- Management

What is the best training delivery methods for PLC?

- Blended Learning

-

- On-site

- Seminars

- Computer based training

- On-line courses (video courses)

- Books

REF: https://bin95.com/Why_onsite_training.htm for comparison chart.

With the typical PLC training providers, what real world educational areas do you feel are lacking?

- Terminology

- Real-world Application of knowledge

- Maintenance (perspective)

- Applying the 80/20 rule to subject matter

- Management of automation

- Troubleshooting (with PLCs)

- Safety (working with PLCs)

In what ways does automation education vary by country, industry, training provider?

- Brands

- Topics needed

- Quality

What is a PLC?

How do you describe a PLC to the laymen?

A micro-computer designed for one specific use, implanting sequential task. We have a great video demonstrating this. The comparison is a person turning on a light.

REF: https://www.youtube.com/watch?v=hkkjcS5AGEs What is a PLC video

What PLC types are there and how to select?

- 3 basic sizes

- PLC or PAC

- AC-DC

REF: https://www.youtube.com/watch?v=QoIi9QohskU What is a PAC video

How do you program a PLC, what is needed to know?

With latter Ladder Logic, basically drawing an electrical diagram. With PACs, there are 4 other programming languages, but it advised to use those other languages, only if the application demands it. PLCs are programmed in a sequence of events. In our live PLC training, we teach best practices. Like …

Never use a latching bit unless absolutely necessary.

REF: https://plc-training.org/plc-programming-training-BP6.html PLC Programming Best Practices

How do you do PLC troubleshooting?

Most people when asking to learn “PLC Troubleshooting” they are not referring to troubleshooting the PLC itself, but instead referring to how to troubleshoot complex machinery using the PLC as a troubleshooting tool. The PLC makes it super easy, based on symptom, you divide (chose relevant input or out) and trace back. The way we teach, it takes on an average 12 minutes using a PLC to find problem, requires of machine/system complexity. In contrast, the hunt and peck method with ohm meter can take hours to days to find the problem.

REF: https://bin95.com/cnc-maintenance-plc-troubleshooting.htm Using PLC Troubleshooting CNC example

And https://www.linkedin.com/pulse/troubleshooting-industrial-controls-don-fitchett/ Troubleshooting PLC itself

How does a PLC compare to other automation control methods?

A PLC is much more much more cost effective and reliable than relays, computers, DCS and PACs. A PLC is much more cyber secure than a PAC.

How do you select a PLC brand?

- Best to standardize, use one brand for all of your equipment.

- Most popular brand for your country.

- Most popular brand for your industry.

- Initial cost and expandability.

PLC Industry:

What industry uses PLCs the most?

- Manufacturing

- Process industry (like oil, gas, chemical, etc.)

- Building industry (elevators, cooling towers, pumps, water fountains, etc.)

- Municipalities (waste and water, power, traffic lights, etc.)

- Transportation (ships, trains, air etc.)

- Msc. (tractor, car compactor, St. Louis arch, car wash, amusement rides, etc.)

What new industries will utilize PLCs?

- Restaurants

- Homes (security, automation)

- Increase in Farm, entertainment and renewable energy fields.

Are there enough trained in PLCs to handle the industry’s current needs? (loaded question J)

Yes, generally speaking. Enough properly trained? NO, not even close.

REF: https://bin95.com/plc-training.htm Source for proper PLC training

Managing PLCs:

What areas of PLC and related automation control management do see most lacking in industry today?

All of them. There is currently virtually no automation management in facilities.

REF: https://bin95.com/maintenance_management_plc.htm Managing your PLCs and Automation (+ free PLC audit spreadsheet)

If you had to pick the top three areas of automation management that need more attention, what would they be?

- safety-education

- maintenance

- programming standards

PLC future:

Will the PLC be dominant in future automation control technology?

Yes. There may come a point where PAC usage is more dominant than PLCs, if cyber warfare doesn’t escalate before then, but then the industry will return to PLCs again.

REF: https://bin95.com/Industry40inUSA.htm Industry 4.0 in USA: Risk (IIoT)

What new applications of PLCs will we see in the future?

- Home (security, garage door, lighting, etc.)

- Commercial (restaurants, stores,

- Robotics support

Side note: 1/3 of USA fight technological evolution and South Korea, Singapore and Germany are miles ahead of the USA, in industrial robotic usage. So future PLC support for Robotics is referring the rest of the world.

What PLC application would you like to see more of in the future?

Predictive Maintenance (PdM)

REF: https://www.controldesign.com/articles/2015/22-tips-to-ensure-control-panel-maintainability/ PLC Control Panel Design for Maintenance

What is the most critical area in automation control that will need addressed in the near future?

Cyber security

REF: https://plc-training.org/plc-network-to-hmi-scada.html PLC Network to SCADA HMI to HTML5 or Smartphone

Subscribe to our YouTube Channel

Business Industrial Network

BIN95.com (Veteran Owned Small Business)

9205 W Russell Rd.

Suite 240

Las Vegas, NV 89148

From The Podcast

Bosspitality - Developing Chief Engineers and Facility Managers Into Leadership Experts

Nick Lawniczak from Bosspitality reveals all of his experiences from being the Chief Engineer. Everything from leadership strategies, training, technical advice and killer tips, and tricks so you can be ahead of the curve with your hotel engineering career or keep up with the latest trends as the Chief Engineer or Director of engineering. Discover what other Chief Engineers and industry professionals are doing to not only advance their career but, to stay at the top of their game, From, automation, outsourcing, hiring, training and development, technical training, building authority and trust, preventative maintenance, personal development, leadership, managing teams, getting things done and everything that works (and doesn't work) to help you better understand how to crush it with your career.Bosspitality is a coaching company for Engineers of all levels. From entry-level technicians to Chief Engineers, Facility Managers and anyone aspiring to be in those positions.Offering one-on-one coaching, experiential training events, and online productivity products.The mission is simple:“Holding Professionals Chief Engineers and Facility Managers Accountable to Fulfill Their Greatness”Engineering can be a very attractive career path, but it can also be extremely competitive. Standing out amongst the competition requires more than ambition.To me, coaching is not only about helping professionals put more money in their pocket, but also helping others become the best version of themselves while achieving their goals beyond what they ever thought possibleJoin Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

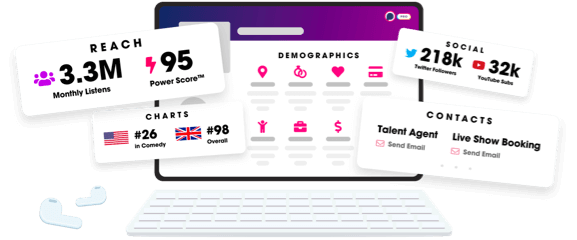

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us