We are living in a world where technology is the master of change; in our lives, our businesses and our society. These changes are pushing the fashion industry into uncertain territory. Change is a great divider: some fear it, some dismiss it, but it is the companies that embrace change and use adversity as a jumping board for innovation that are going to stick around.

And it’s agility, in my opinion, that is the absolute key to making a success out of the uncertain ‘fashion future’ we find ourselves in. Fast-fashion companies have proved that vertical models, close-to-season systems and speed manufacturing are the secret to survival. I’ve often wondered recently how large companies with a vast global supply chain, long-lead product development schedules and wholesale structures can alter their approach to compete.

Levi Strauss & Co are arguably the world’s largest and longest running denim giant with nearly 14,000 employees worldwide, products in about 50,000 locations and a global network of manufacturers located across 25 counties, so it would be understandable to forgive them for moving slowly. But, on the contrary, in recent years they have thrown themselves into the future with a gusto unrivalled by most start-ups. And today they’ve just taken a giant leap for denim-kind; they’ve made a radical breakthrough that will transform how jeans are designed and developed and maybe even how they are sold in the future. Whilst doing all this, they’ve managed to create a system that’s cleaner, safer and smarter.

“Our goal was to tackle two predominant industry challenges — being able to respond quickly to changing consumer trends, while making the manufacturing process more sustainable,” said Chip Bergh, president and CEO of Levi Strauss & Co. “We are addressing both agility and sustainability without compromising the authenticity our consumers expect from us. This is the future of jeans manufacturing, and LS&Co. is well-positioned to lead the way.”

Levi’s Eureka Lab, San Francisco

Levi’s Eureka Lab, San FranciscoLast Thursday I was invited to meet with Bart Sights, the vice president of technical innovation at Eureka Lab (Levi’s innovation center in San Francisco) for a secret unveiling of the brand’s latest advancement. The last time I saw something like this it was project Jacquard, the commuter jacket designed in collaboration with Google, so I was expecting a new product release, a range or a technical garment. As I walked onto the lab floor, the innovation was lying right there in front of me but I failed to see it. The usual 501’s lined up in the denim lab looked exactly like a classic Levi’s wash-range; an array of authentic laundries, vintage replications and fashion-driven finishes. I was stood in the middle of the floor asking Bart to give me a hint as to what I’m going to see, when I was already looking at it. You see, the innovation wasn’t in the design, it was in the process behind the design. They’re calling it F.L.X. (Future-led Execution) and if you know anything about denim manufacturing, it will blow your blue mind.

Levi’s F.L.X. Washed Garments at Eureka

Levi’s F.L.X. Washed Garments at EurekaThe inspiration for F.L.X. started with LS&Co’s ongoing partnership with Jeanologia, a leader in eco-efficient solutions for fabric and garment finishing, particularly laser. Our industry has been waiting for the moment laser becomes sophisticated enough to replace hand sanding and chemical treatments for a while. Some have embraced it to work in conjunction with other processes but nobody has gone the whole way. Levi’s decided not to wait, they decided that they wanted to make it happen 18 months ago and have been secretly working away behind locked doors and down hatches in basements to make it happen. See below time-lapse video for a teaser:

I’ll come to all that in a minute but for now I want you to imagine what would happen if you did manage to create all your denim finishes using a three-step process; a simple base wash completed at the factory where the jean was made, one laser treatment in the USA and a final short post-wash to remove laser ash (that allows for a further garment tint for flavour if needed)

If you’re like me you’ll be thinking about two main elements that will be cut: time and chemicals. We all know that the jeanswear world is a dirty business, creating blue rivers in Guangzhou, wasting an incredible amount of water, using a cocktail of chemicals, and generally fucking our planet over. Not to mention the jobs in dry and wet processing being repetitive, laborious, archaic and one of the least desirable in the wash house. Staff turn-over is high and although it may have been deemed technically ‘ok’ seeing these lines of technicians spraying potassium permanganate on denim or vigorously hand-sanding whiskers, I don’t think anyone would agree it made their hearts soar. But the consumer’s lust for laundered jeans has led us to create a business that makes these jeans by the millions every week. Even a company like Levi’s works huge numbers:

“30 years ago when I started, there were three finishes” explains Bart “dark, medium and light: rinse, stonewash and bleach. Fast forward to today, we do 1000 finishes every season across men’s, women’s, kid’s, etc. And if you added up all the different chemicals we use from around the world with all our different vendors, its way over 1000 chemicals. Here at Eureka, we used to create what we called ‘Blue Books’ which are a manual of all the steps that you have to go through to create a certain wash. Our recipes would be 15, 18, 20 steps long”

And now?

“Now almost all of our washes are 3 steps long and we use a few dozen chemicals, total. There’s no permanganate in this building and there hasn’t been for months”

So why have Levi’s cracked it when other companies are still either using traditional methods or layering laser with hand-work?

“In the past we all told ourselves that laser wasn’t sophisticated enough, somewhat for self-preservative purposes. I mean we all built careers on this! Maybe the industry could have done this 5 years ago but nobody said ‘were going all in’. When we said ‘we’re going all in’ and by that I mean using only laser and nothing else, up popped these moments:

‘oh shit, what about that?’ or ‘oh shit what about this?’

…but we haven’t let that limit us, if we have come across an obstacle like that, we have invented a solution for it”

Eureka Lab before F.L.X: the dry processing stations.

Eureka Lab before F.L.X: the dry processing stations.So lets play devils advocate for a second: laser looks good, sure. But I’ve not seen it great enough to stand alone. It lacks the dimensional aspect of natural whiskering, denim character and those elusive highs n lows. There are some digital tools out there trying to do the job but as Bart explains, a lot of them are built on physics models and rendering and are “sort of cartoonish” So Levi’s built theirs in-house. Their team of wash experts, technicians, chemists and designers have now become ‘Digital Craftspeople’ rendering 3D, photorealistic drawings on computer. Eureka Lab has dismantled their hand-sanding stations downstairs and turned a room upstairs into a state-of-the-art digital laundry. Interestingly the files they create look very similar to the 3D whisker templates you see at a laundry, but these can take days to create, see a speeded up example below:

https://denimdudes.co/wp-content/uploads/2018/02/Denim_Dudes_Project_FLX_02.mp4

“So for example, Ben who was integral to developing our imaging tool was originally hired as washing machine mechanic” Bart tells me with a smile “Our team are capable of seeing the future of their expertise and are on board to adapt. That’s why I’m so proud of them. They’ve been working on something for 18 months that they knew was radical, they had to allow themselves to be vulnerable enough to go for it. Because the fact is, the very thing that they’re working on could make their job redundant at any moment.

And is there a chance of redundancies?

“If you trust that you work for a great company that is putting a stake in the ground, you trust will be re-trained and you will end up bringing things to the table you didn’t even know you had inside of you”

Bart’s team have done exactly that and its frankly inspiring to see.

OK, first hurdle over, now this operation must be scalable. And this is where it gets really interesting (and a little bit Breaking Bad too) Levi’s have distribution centers all over America and one not far from San Francisco in Henderson, Nevada. In a covert operation, Levi’s converted the basement of the Henderson location into a laser-lab. Down a secret hatch is a whole floor of Jeanologia machines where staff can download a rendered finish file from the Eureka Cloud and execute that onto the pre-washed bases sitting upstairs in the distribution center. A batch of jeans can go down the hatch in the morning and be back upstairs, ready to go by the evening. Now that’s some radical close-to-season.

Levi’s Digital File in a Jeanologia Machine

Levi’s Digital File in a Jeanologia MachineAnd not the close-to-season that exists right now either. This system is superior to fast fashion because of the waste factor. We’ve all seen the racks and racks of unsuccessful, unsold items on mark-down in stores and we’re all talking about the issues of post-consumer and industrial waste, over-production and landfill fashion. By a simple re-order in the manufacturing process, jeans can be processed almost days before going into store and overnight Levi’s can shift their 12-14 month business to a ‘make what you sell’ model.

Perhaps the smartest element to this process is that it combines the bespoke accuracy of a tiny company with the scalability of a fast-fashion giant.

And the retailers are already loving it. Levi’s have started secretly briefing their most trusted key retailers and the response is overwhelmingly positive. Paige Thomas, Executive Vice President and General Merchandise Manager for Men’s and Kid’s at Nordstrom Inc. is excited:

“One of the biggest challenges we face as an industry is ensuring we have the right products at the right time as well as the ability to respond to our customers’ evolving needs with speed. The team at Levi’s is working towards this challenge by contributing to the future of the apparel industry as one that’s both agile and uncompromising on quality, while improving sustainability” she says.

So the retailers are excited, the vendors were all informed 12 months ago and have fully embraced the new system, the tests have been done, the first laser-lab is up and running, what’s next? Well its simple really; they start. The hope is to be fully scaled by 2020.

I don’t know about you but my head is spinning a bit. I think it’s amazing how this was going on within the walls of the magical Eureka Lab all these months. I cast my mind back to when I first visited the facility and had the sense that the place was electric with inspiration. Back then I was inspired that such a corporate company had the confidence to invest in a small, renegade crew of finishers and chemists. I felt like they were really investing in the creativity of their staff, creating a refuge for designers to think outside the box. I guess what I didn’t take into consideration was the fact that this team are not just creative people who need to get their hands blue from time to time. These guys are pioneers. You give the right people the right tools and they will do more for you than you could have dreamt. More than they could have dreamt.

“When we built Eureka five years ago, this close to the senior decision makers at head office, we realised we had a unique opportunity to redefine the future” Bart tells me “so we tried to staff it with an unorthodox diversity of talent and state of the art equipment and create this environment that could be truly disruptive”

And disrupt us they did. I’m sure a lot of you will have your thoughts and opinions about this radical new system and to many it will seem so far from the ‘normal’ that we’ve got used to. But remember, 30 years ago we’d have thought the lines of hand-sanding stations and PP spray operators was far from normal. After talking with Bart for nearly two hours we found ourselves where I often find him on a visit; sitting on the floor of Eureka, surrounded by jeans. I looked around and this favourite quote of mine popped into my head:

“The electric light did not come from the continuous improvement of candles” * I said. We all laughed and nodded. Meeting adjourned.

*Oren Harari, business professor at the University of San Francisco

Bart Sights at Eureka Lab

Bart Sights at Eureka Lab

From The Podcast

Denim Dudes

Denim Dudes is known for its unique community of denim experts, enthusiasts and aficionados. In this podcast series, we interview some of the most influential and passionate people in the business. If you work in the industry and want answers and insights into today's pain-points and emerging trends or if you simply love jeanswear and want to learn and connect, this is the place for youJoin Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

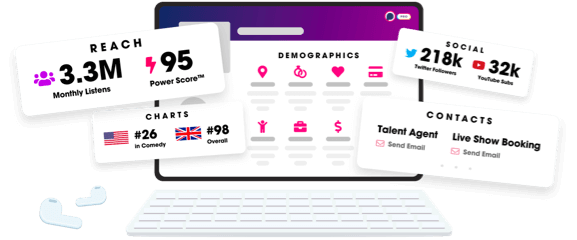

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us