Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:01

Hey. Welcome to another episode of Handmade

0:01

Pennsylvania. My name is Josh Myers, and I'll be your

0:04

host. Today, we're going to hear from a knife

0:06

maker based out of Green Lane, Pennsylvania.

0:10

Check it out. All right.

0:17

Hey, Jesse. How are you doing? Good, man. How are you doing?

0:20

Great. I really appreciate you taking the

0:20

time to talk to me.

0:22

So you're from Marlboro Handcraft and you

0:22

are a knife maker?

0:27

Most. Most of the time. Some of the time.

0:29

Okay. So how did growing up.

0:33

That's fair. How did you get a knife making?

0:36

That's not something everybody just kind of decides. One day I want to go play with grinders and

0:38

pieces of metal and make them sharper.

0:43

Well, full time.

0:46

I'm not a full time knife maker. I'm a part time maker.

0:48

I work I've worked full time for about a

0:48

decade doing sheet metal work.

0:54

Okay. So I run motor jets and all kinds of really

0:54

expensive tools that are cool for about 20

1:00

minutes and then boring for the rest of your life. Right. So I've been around all the metal

1:02

working stuff for years, and before my wife

1:08

and I had our first child, I built

1:08

motorcycles for fun.

1:12

So that was how I killed all the free time,

1:12

killing all that, having a creative outlet,

1:18

all that stuff. And little known fact

1:18

motorcycles are really expensive to build.

1:24

So after my son was born, there was.

1:27

It's much less free income. But I have access to metal and grinders and

1:29

all that stuff.

1:35

There's a guy from Texas that's a maker

1:35

that's in the motorcycle scene, so I saw his

1:40

stuff on Instagram. So I did stuff, was really cool, started

1:44

doing a lot of research on YouTube and Google

1:48

and all that stuff because that's what being

1:48

an adult is.

1:52

And it just snowballed from there. So I made my first life about three or four

1:53

years ago, maybe five years ago, and it just

2:00

kind of I kept making them. And then friends would ask and then it

2:01

slowly built from there to putting them

2:07

online, and it just snowballed from there.

2:10

It's really all it was. It was just me being poor.

2:14

Well, and having a way to get that creative

2:14

juice out kind of, you know, exercise that.

2:20

So you said you started selling them online. Was that on Etsy or just your own Web.

2:23

Page or something? We tried. My wife and I originally did.

2:28

She did some like jewelry stuff. If you go back way back in my Instagram

2:29

feed, there's some like small jewelry that

2:33

she was doing and she just ran out of time

2:33

and the knife stuff really just took over

2:40

everything. But we tried Etsy.

2:42

We never found any success with that.

2:45

Okay. Everything we've done or everything I've done

2:46

has been Instagram.

2:49

I've done a few shows here and there, but

2:49

it's been predominantly word of mouth and

2:54

Instagram. Yeah, so you do.

2:57

A few times throughout the year I've seen

2:57

Raffles, which I thought was pretty cool.

3:00

I'd never seen like a sales style quite that

3:00

way, and I thought it was a neat way to kind

3:05

of get people in without committing to a

3:05

large thing and just kind of spreading the

3:09

word. Was that something that you saw other

3:09

people do and you took on yourself?

3:14

There's a lot of different ways that the

3:14

community sells their goods because they can

3:18

be pretty expensive. You know, it's a it's a long process to

3:20

make.

3:23

And so when you buy a knife, where you're

3:23

paying for is a lot of time.

3:27

So that's why they tend to be really

3:27

expensive.

3:31

And most people don't have like I don't have

3:31

that I got in the knife maybe because I

3:35

thought they were cool and wanted to make one. So I get that they're not.

3:40

It's a little bit of a pricey item.

3:42

So the raffle and the auction stuff is a

3:42

great way for people to.

3:47

Can't necessarily afford it right out of the

3:47

gate to kind of get started dipping their toe

3:52

in and getting excited about it. And seeing some different designs.

3:55

Because you have a I mean, there's more than

3:55

just one design a knife you make.

3:59

There's like the mini skinner. I know I personally have the fisherman's

4:00

friend, which is a great everyday carry

4:04

knife, but is there a set number of styles

4:04

that you have or.

4:09

No, what happened was I get I'm a little.

4:15

And I guess I get really I kind of jump

4:15

around from thing to thing, so I'll make a

4:21

knife and then. It won't be as exciting to

4:21

make the eighth time or whatever.

4:26

So something else. And then customers will ask for something.

4:30

And if I love it, I'll keep it around.

4:33

Another customer asks for the same style

4:33

knife.

4:37

Just kind of whatever I'm part, partially,

4:37

whatever I'm in the mood for and then.

4:42

Like I never made a I had a customer order,

4:42

a letter opener, which I never thought I

4:48

would ever make in my life. It is kind of like a dull knife, right?

4:52

Kind of the idea. And that's what they

4:52

wanted.

4:55

That's what they got. So that's how I

4:55

started making letter openers, you know?

5:01

So it's probably still interesting. Customers happy, the customer is happy and I

5:02

love making knives, so it all worked out.

5:07

But yeah, as far as making a style in knife,

5:07

it's just kind of.

5:14

Whatever floats my boat or wherever. I think if I'm having a tough time selling

5:16

something, maybe I work my way into another

5:22

style to try and see where the market's

5:22

going or things along those lines.

5:26

But so how does it.

5:29

So if you want to design your own style,

5:29

like you'd want to adapt something you saw,

5:33

do you just draw it out on paper and trace

5:33

it onto a thick block of metal and.

5:40

Yeah. Yeah. Basically, if it's too big to fit

5:40

on a sheet of paper.

5:44

Right, it's taped to together, but then it's

5:44

all pencil.

5:47

And I'm a horrible sketch. I'm not an artist, you know?

5:51

Me neither. But I'll sit and, you know, it's

5:51

usually I'll if any of that stuff, it's I'll

5:56

put a baseball game on. And if it's baseball season or a football

5:57

game or whatever, have a beer and get out of

6:01

pencil and basically draw out a rough length

6:01

of blade that I'm looking for.

6:06

Kind of. Look at a few things online to get

6:06

an idea of if I'm making a kitchen knife, how

6:14

big of a radius do I need along the blade of

6:14

the knife and things along that nature?

6:19

But other than that, it's just kind of keep

6:19

drawing until it looks right and a lot of

6:22

erasing. And then, yeah, cut it out, put it

6:22

on a piece of steel and trace it out and

6:28

start cutting from there. So when you how do you cut the steel?

6:32

Is that ground out or. I think I saw one of your old pitchers.

6:36

I went back to the beginning of your

6:36

Instagram and it looked like there was like a

6:39

long sheet that maybe had several cut out.

6:42

Is that always kind of how it starts? It depends. It depends on my supplier has

6:44

their steel, but a lot of times it will come

6:48

in in a roughly four foot long chunk that's

6:48

three inches wide.

6:53

And then usually you try and make them fit

6:53

as tight as you can so you get as many knives

6:57

out of it. That stuff's not cheap, right?

6:59

But as many as you can. And then. Like I was saying, I work in a

7:00

metal shop, so I have access to a pretty

7:06

badass band. Okay, I'll use that.

7:10

I have a cutoff wheel here. If I get a wild hair up my butt that I got

7:11

to do it at home, you know, it just.

7:15

However I got to do it is kind of how I got

7:15

to do it.

7:18

I'm not I'm not really set up to have a

7:18

knife shop where I live.

7:23

It's it's very. It's in my basement, so it's very.

7:28

Crammed and we make it work because this is

7:28

what we have.

7:32

So I do a lot of I do a monthly cleaning,

7:32

write vacuum, everything.

7:37

I take everything off the shelves, wipe them

7:37

down.

7:39

I haven't done it like two months. Don't tell my wife. But yeah.

7:44

So we keep everything cleanly, but it's it's

7:44

very seat of my pants around here.

7:48

All right? That's just how we have to do it right now.

7:51

I think that's true for a lot of makers. It's just it's a part time business.

7:54

You have a life, you have a full time job,

7:54

and it's just on the side.

7:58

And I mean, even doing laundry like normal

7:58

things always kind of falls by the wayside

8:02

for me. So, yeah, cleaning up the shop is a

8:02

whole nother layer of activity that I don't

8:07

jump into all the time. Yeah, well, it's for me.

8:10

It's. I'd be. It'd be.

8:13

A lot of the knife making that there's an

8:13

old saying that it knife making is taking

8:20

something and turning it into dust and

8:20

what's left is the knife.

8:23

So basically you're starting with blocks of

8:23

stuff, steal your woods for handles and all

8:29

that, and you're removing everything. And what's left is the knife wheel.

8:33

All that stuff that you removed just turns

8:33

to dust and none of it's good for you.

8:37

So I wear a respirator 99% of the time when

8:37

I'm working, but I try to clean all that

8:43

stuff up as much as I can, because even

8:43

having it in the house is now I'm in the

8:47

basement, so it's not terrible. But I like we do our laundry in the

8:49

basement. We do. I mean, a lot of our life comes from

8:51

the basement up to the up the steps.

8:56

We try to keep it as clean as we can.

8:58

So I'm not pulling all that stuff around me. I don't want to go kiss my kids goodnight

9:00

and be shaken metal dust all over their bed

9:06

and stuff. So we.

9:09

Co mingles a little bit. But yeah, yeah, they're going to grow up

9:10

immune to some special stuff, but.

9:15

Maybe become superheroes or.

9:19

My son would be thrilled. Yeah, because I know for some crafts, like

9:21

woodworking, they have some dust collection

9:26

systems, but there's not too much you can do

9:26

for for knife grinding, is there?

9:31

Like the metal stuff you have to get a little. People get a little wary because you're

9:36

throwing sparks.

9:39

When it comes off the knife, it is. Glowing hot right there, teeny tiny sparks.

9:45

But so you can't put that into a lot of dust

9:45

collection systems because it'll ignite all

9:50

those woodchips. But as far as the wood like

9:50

the handle material, when I'm grinding that

9:54

off, I have a vacuum going right under my

9:54

grinder that pulls a lot of that out of the

9:58

air. And then when I'm when I'm grinding

9:58

knife handles, I vacuum every night when I'm

10:04

done. Okay. That stuff gets everywhere, but

10:04

most of it goes straight below me, but it

10:12

just iterates everything. So I kind of I'll

10:12

vacuum all the floor and my workbench and

10:16

then I'll kind of sit around and, like, wave

10:16

my vacuum around in the air to try and pull

10:20

as much out of the air as I can. It doesn't do a lot, but every little bit

10:21

helps.

10:24

But they do make a lot of actually, I was

10:24

looking today there is a system that is.

10:31

You can move it around and it pulls all the

10:31

air down.

10:33

A lot of dust collection systems pull the

10:33

air up, which for me would be really back to

10:38

your towards our living space.

10:41

But they make I'll have to I'll post

10:41

something about it online but it's $500

10:46

little thing that wheels around and has

10:46

replacement cartridges looks cool I'm going

10:51

to look into it because. So is it like a filter or more just kind of

10:53

knocks it down so it's not.

10:57

Airborne, pulls it through, it basically runs

10:57

air through a filter, the dust stays in the

11:02

filter and then fresh air comes out of the bottom. The thing is, look, layman's terms as best

11:04

as I can figure out the job.

11:10

Yeah. Yep. Well.

11:13

So are there. Do you deal with more than one type of metal

11:15

for the knives?

11:22

In simple terms, no. In debt?

11:27

Technically, yes. Ideal only in carbon steel.

11:31

Okay. Which is if you think of steel versus

11:31

stainless carbon steel, if you chuck it out

11:37

in the snow or the rain and bring it inside

11:37

soaking wet and let it air dry, you're going

11:42

to have rust all over. Those are the style knives that I make.

11:44

I don't deal with stainless more for the

11:44

heat treating aspect of it.

11:51

It's a lot. You need more technical

11:51

equipment to heat treat stainless.

11:57

There's higher temperatures that you need to reach. You need to reach them and maintain them for

12:00

a longer amount of time.

12:04

Whereas carbon steels typically are easier

12:04

to harden.

12:10

They're easier to work with. I like working with them more.

12:13

I think it makes a cooler knife. They age gracefully.

12:16

They kind of tell a story. Stainless knives like your the cheap set of

12:18

nine you got for your wedding or that we got

12:23

for a wedding at least is what most

12:23

stainless knives are there.

12:27

It can make a great knife. Doesn't mean it's not a good night, but it

12:29

doesn't really tell a story and.

12:33

Part of what I do or the way I think about

12:33

it is that there's a story that goes along,

12:39

whether it's. You know.

12:42

Whenever the story may be. But there's a story that belongs to the

12:43

knife now.

12:46

Right. Everything you cut with that knife is

12:46

going to embed a little bit of a different

12:51

color onto the actual knife plate.

12:54

So. If you take that away, you still get the

12:54

handle, still looks custom and all that

13:01

stuff. But for me, the way I think about

13:01

knife making, that's what we use.

13:05

So no, I like it because it does get that

13:05

kind of patina to it.

13:09

And like you said, it makes it even more

13:09

unique on top of being handmade and not that

13:15

kind of sterilize machine auto production

13:15

method of consuming, it's it's unique and

13:23

that's why I like leather as well. You get that patina, you get that

13:24

uniqueness, and as it gets older, it just

13:27

gets better. I mean, a scratch isn't a

13:27

defect.

13:30

It's a beauty. Mark, you know, it's what you

13:30

said a story, and it kind of just adds to the

13:35

overall feel of it when you pick. Your old vintage cars aren't cool because

13:39

they look like they just came off the

13:42

showroom floor. The coolest vintage cars

13:42

I've ever seen.

13:47

Look like they've been rolling around the

13:47

world for 100 years.

13:51

Yeah. Yep. Still alive and kicking.

13:53

That's what makes it cool. It's not cool because it came out of this.

13:57

Came out of the factory a week ago. It's cool because it's been around for

13:58

forever and it's living to tell the story.

14:02

That's what makes it really cool. That's what makes it beautiful.

14:05

Yeah. Yeah. I mean, granted, the lines of that

14:05

stuff are way better and all those fun

14:10

things, but there is a soul there that you

14:10

can't replace.

14:15

That's what makes it. That's true.

14:19

As for the handles, I know largely I'm drawn

14:19

to wood, but there's my mom might say this

14:26

wrong. Muqata is another material use.

14:29

And I know you made one with antler for

14:29

somebody else.

14:33

I know. It. Turned out really well.

14:36

Do you have a favorite kind of material or

14:36

is it again just whatever kind of strikes

14:41

your fancy in the. Moment at a lot of time?

14:45

So I have a custom book that I run on.

14:48

So if you get a hold of me and want a knife,

14:48

usually it takes about six months to make in

14:56

your knife. The way that it works is I'll

14:56

get a hold of you the month before I'm going

15:01

to start on your knife, and we kind of hash

15:01

out what you want, chef.

15:04

Knife do you want hunting? Knife What do you want?

15:08

And part of that process is.

15:12

What kind of materials do you want? How are you going to use them? How are you

15:13

planning on maintaining the knife?

15:16

Wood's going to take a little and not a lot,

15:16

but it's going to take a little bit more care

15:21

than a lot of the manmade materials are.

15:25

So a lot I don't have a favorite material.

15:27

I love them all. They all have totally

15:27

different vibes.

15:31

They add different textures to the knife.

15:34

They add different. Now it's all different, but it can achieve

15:36

great things at all.

15:41

I don't have some of them smell worse than

15:41

others.

15:44

That's the biggest that that antler knife

15:44

that it smelled like somebody died next to.

15:52

It was horrible. It came out awesome. It's one it's

15:53

beautiful. When you're done working it, it's like

15:56

lighting your hair on fire.

16:00

Can ask. It's terrible. And I had no. I had an inkling that it

16:02

smelled bad when you worked it.

16:07

I had no idea how bad. I I'm very tempted to tell people I'll never

16:08

if it didn't look as good as it did, I'd

16:13

never do it again. It looked amazing.

16:16

It really did look cool. Especially with that. The iron was of a

16:18

spacers is what they called just the.

16:22

Yeah. Just a well they had a liner.

16:24

Your liners are between the tang and the

16:24

knife and then the handle and then a spacer

16:28

is going to be between like pieces of

16:28

material.

16:31

I don't have a knife on hand to really

16:31

demonstrate it, but.

16:35

Okay. Minor goes between the tang of the

16:35

knife and the handle material.

16:40

Yeah, just like that. And then spacers kind of.

16:43

Yeah. Gotcha. So are the liners then?

16:48

Is that just cosmetic or is that is there a

16:48

function to them that they kind of have a

16:52

purpose nowadays?

16:55

It's more cosmetic than anything back in the

16:55

day.

16:59

So when you're making a knife, we have to

16:59

think about if you go back to your high

17:03

school physics class. Steel expands and contracts based on heat

17:06

entirely differently than wood will or any of

17:13

your car does or your bone.

17:16

So what happens is the wood is trying to

17:16

work its way off of the knife because it's

17:21

expanding and contracting at a totally

17:21

different rate than steel will.

17:26

What those liners do is kind of create a

17:26

buffer between the steel of the knife and

17:31

then the handle material so that it doesn't

17:31

want to work its way off.

17:35

Nowadays, they stabilize most woods, which

17:35

means wood has air pockets in it.

17:43

And what stabilizing is quickly is you

17:43

replace all those air voids with a heat

17:51

curable resin. So now it's basically a plastic that looks

17:52

like wood.

17:58

Okay. Okay. So what happens is it doesn't want to come

17:59

off your knife.

18:02

It's not going to the ability for it to.

18:06

Change its size based on how hot or cold it

18:06

is, ambient temperature and humidity and all

18:10

that stuff goes away. Okay. So so those liners really are cosmetic

18:12

nowadays.

18:18

They look cool. A little contrast and yeah.

18:23

A simple knife with wood scales looks great.

18:26

You can really kind of beef everything up

18:26

and add a lot of dimension.

18:31

Visual. What?

18:34

Chutzpah. Chutzpah. So is that a.

18:38

Like if somebody want to start out making a

18:38

knife and say they got a piece and they got a

18:41

band saw and they cut out their template and

18:41

they're kind of grinding the shape and and

18:45

make in their hand. Where do you get the spacers from? Is that just something you Google?

18:48

Is that or that there is this I'm sorry. Online, there are a million.

18:52

It's just so you have like Tandy, right?

18:55

And things like that for leather working,

18:55

there's a million of them online for knife

19:00

working. Okay. And you go on Instagram and just start start

19:01

following people.

19:06

I follow and you'll follow. You'll find every supplier of.

19:12

Everything you could possibly need to find.

19:15

I did see that panel. Just send me a message, all right?

19:21

Yeah, because there was I mean, people just

19:21

make a business out of simply selling the

19:25

scales, just the the wood pieces that are

19:25

kind of pre shaped and, well, I guess.

19:30

Are usually cut down to a closer, a more

19:30

usable thickness for a knife handle.

19:38

So three eights is kind of pretty thick for

19:38

a knife.

19:40

Or at least. At least. 3/8 is about as thick as I start with.

19:45

I actually do a lot of machining to my knife

19:45

scales to get them down to a thickness so

19:49

that they're nice and perfectly parallel

19:49

makes shaping a knife handle a lot easier.

19:54

It also means that where they meet up to the

19:54

knife tang.

19:58

Is flat, which means there's no gaps for

19:58

anything to get into.

20:03

Or there's it's a solid connection between

20:03

the knife and the knife scale.

20:09

So it's perfectly machined flat.

20:13

But you can get it in most knifes if you're

20:13

buying knife scales, they're cutting it down

20:18

to a size just so it's easier for you to not

20:18

have a really nice band in your basement.

20:23

It's all a little less material to cut off

20:23

and leave on the floor and dust.

20:27

Yep. So how do you.

20:32

So I'm still just kind of going through the

20:32

process in my head.

20:34

Just curious myself. You have the general shape.

20:37

And then as for the actual angle, when

20:37

you're coming down to the point of the knife,

20:41

is that all by hand? I mean, I'm saying I'm pointing the knife,

20:43

but the actual blade part that you.

20:45

Cut with the actual bevels are let me grab a

20:45

knife.

20:49

Just makes my life easier. So you're talking this section of the knife.

21:03

That's the main bevel of your knife. That's. There's a million different ways to

21:05

do it.

21:10

I do it by hand. I'll scribe a center line down this portion

21:12

of the knife.

21:17

So you take the knife like that? Put it that way. I'll scribe a center line

21:18

here, and then you just grind everything to

21:24

the center line, and then you grind slowly

21:24

down this way.

21:27

Okay. They make a million jigs that help you hold

21:28

the knife in a perfect.

21:34

Angle. I mean, you just keep dragging it across. You know, you have a tool rest.

21:40

Put the jig on the tourist. Keep dragging it across and keep dragging it

21:41

across. That makes a perfect angle on both sides.

21:46

I've just always done it that way where I

21:46

just hold it in my hands and grind my bevels.

21:52

If you gave me a jig, I probably couldn't

21:52

use it.

21:55

I would probably make garbage knives. There's people that get all up in arms.

22:01

If you use a jig, you're a liar and a

22:01

cheater.

22:05

And it's stupid. It's just like any different craft.

22:10

There's people that get you're not you're

22:10

not doing this enough if you're making a

22:17

decent product up there. Long story short, you can you can do it.

22:22

There's a million ways to skin a cat. The way I do it is hold the knife.

22:27

Set my belt set. So you basically bring your edge in to set

22:29

where your edge should end up and you grind

22:34

everything down to there or from there.

22:37

All right. So you set your edge and you just

22:37

keep grinding and grinding and grinding.

22:42

And the tighter you get down to the bottom,

22:42

the easier it cuts through everything, the

22:46

thinner the quicker goes through anything. Right. Right. And then for the the scales,

22:48

once you have I mean, I guess that's kind of

22:53

the last piece. I imagine you get that that beveled edge on

22:55

there before you put the scales on and

22:59

everything. Yeah. So. So this knife is ready to put

23:00

scales on, right?

23:05

It's hardened. The Bevels are in. There's not an edge on

23:07

here, right?

23:10

Like no edge. Because when you're grinding your handle,

23:12

God forbid you slip and you put an edge right

23:16

into your thumb. That would suck. Which I do a lot anyways.

23:20

Um. But that's going to get handled.

23:24

Scales put on it, shape everything down, and

23:24

then once that shape down, then I'll put the

23:29

edge on and then it goes out the door. Okay. So then you shape the handles again,

23:32

just kind of by eye by hand to get those the

23:36

fingers move and. Well, I was saying how like I'll flatten them

23:38

down really.

23:42

I'll make them almost perfectly flat and

23:42

then I'll scribe I'll, I'll pencil draw lines

23:47

all over the place where things need to end

23:47

up roughly kind of very geometrically.

23:55

And I'll do all that on the grinder.

23:57

And then once it's all geometrically done,

23:57

I'll smooth everything out on The Grinder and

24:01

then I hand sand from there. So once it's pretty close off the grinder,

24:03

then it's all hand sanding.

24:07

Okay? And then once hand sand the handle put

24:07

the edge on and you're done.

24:12

Little oil. Maybe I put I put mineral oil on everything

24:13

because it's food safe.

24:19

You can get it at every pharmacy on the

24:19

planet.

24:24

Wal mart, whatever. My boss is a beekeeper, so I make a mixture

24:27

of beeswax and mineral oil to coat everything

24:34

because wax is the greatest water repellent

24:34

on the planet.

24:38

And water and steel don't mix well.

24:41

Right? So I'll put a good coating of that

24:41

beeswax on.

24:43

And then out the door it goes. That's sweet. So.

24:51

I know you said you did some in-person sales

24:51

and you do most of it on Instagram.

24:55

Mm hmm. Is in-person something you think you want to

24:56

do more of, or is that just kind of as they

25:01

come up and you have inventory to kind of

25:01

move?

25:06

The kind of explain this.

25:11

I usually am. So right now I'm in the middle of.

25:15

How many times do I have to.

25:18

Four, six, seven. I'm in the middle of a seven knife batch.

25:23

I do things in batches. It makes things.

25:27

I'll get all the knives profiled, then I'll

25:27

heat treat everything and then I'll grind all

25:32

my bevels on and then I'll put all my handle

25:32

scales on and it cuts down on the time that I

25:37

have to spend on per knife.

25:40

If I was doing one knife at a time, it's

25:40

just like a restaurant.

25:44

If you have all these orders come in, you

25:44

don't do the first ticket.

25:47

Send it out the door, do the next ticket. You're always working on all the tickets you

25:49

have. So it's a similar process for me.

25:55

If I do one knife at a time and send it out

25:55

the door.

25:59

I spend. An ungodly extra amount of time on

25:59

stuff.

26:03

So heat treating if I heat treat them all.

26:06

It takes 40 minutes to do six knives, get

26:06

them hard or it takes 20 minutes to do one

26:13

knife. Wow. Right. So if I do six in 45 minutes, then I

26:15

have to temper them.

26:20

Well, it takes 2 hours to temper a knife. Well, it takes 2 hours to temper one knife.

26:24

And it takes 2 hours to temper six knives

26:24

six times.

26:27

So I'm saving.

26:31

10 hours if I do six at one time or if I

26:31

versus one at a time.

26:34

Right. What were you asking?

26:39

No, I like that you started talking about the

26:39

temporary because I had forgot.

26:42

I want to ask you more about that. What? At what point do you do that?

26:45

I didn't. I didn't think of that.

26:48

So when you. When you profile your life,

26:48

depending on.

26:56

If I'm doing a kitchen knife, I'll profile

26:56

it, drill holes, put my my logo stamp on it,

27:01

and then I go harden it. And then the moment it's done hardening.

27:05

So when you get a knife hard, you get it as

27:05

hard as humanly possible.

27:10

There's no you can't get it to kind of hard.

27:13

Okay. You get knife steel to as hard as it

27:13

can get.

27:17

Okay. The problem is, is it becomes really

27:17

brittle.

27:20

So if you drop it, it could break. It's too hot. So what tempering is, is it's

27:23

soft, hard, it starts soft.

27:29

You get it as hard as you can and you

27:29

temperate back down so that it's usable if

27:33

you drop it, if you accidentally hit a

27:33

chicken bone with a kitchen knife, it's not

27:39

so hard that your edge wants to chip out,

27:39

that the tip wants to break off all those

27:44

different things so you harden it, and then

27:44

after it's hardened, you immediately temper

27:49

it back. And so if it's a kitchen knife, I

27:49

haven't put any bevels on it because they're

27:55

so thin they want to warp really bad.

27:58

You'll get a big wiggle in them. There's not enough mass in the cross section

28:00

of the steel.

28:03

If it's a hunting knife, carrying length,

28:03

whatever, they're thicker.

28:07

I'll put a much bigger bevel on it so I have

28:07

less grinding to do.

28:11

And it's hard. It's. It's hard.

28:14

Steel is much more detrimental to my

28:14

grinding belts than soft steel.

28:21

So I do as much as I can when it's soft and

28:21

do as little as I can when it's hard.

28:25

But with kitchen knives, you have to almost

28:25

grind the entire knife when it's hard.

28:30

So they tend to destroy belts, which makes

28:30

them more expensive.

28:34

And so what kind of equipment is used?

28:36

Excuse me? To temper. To do the hardening.

28:40

Our kitchen oven. Oh, really?

28:43

Yeah. It only needs to be depending on the

28:43

type of steel.

28:46

It's about 400 degrees for two two hour

28:46

cycles.

28:52

So I actually have a decent thermometer in

28:52

my oven.

28:57

To get actual 400 degrees, but it sits at

28:57

400 degrees for 2 hours.

29:02

They come out, I put them on a cookie tray,

29:02

I put them in our freezer so that they get

29:06

cold and then they go right back in the oven

29:06

for 2 hours.

29:10

So that's usually pot roast night while my

29:10

my wife is cooking a pot roast in the crock

29:16

pot, we use the oven to temper knives.

29:19

Ovens re All right nice.

29:21

And I think to get back what you're saying

29:21

with when you were counting what you had

29:25

going on was asking about the the shows you

29:25

did and just how you approach shows and.

29:32

If I was full time, I would do as many shows

29:32

as I can.

29:36

Because if I was full time, I would probably

29:36

get done.

29:39

I would say 3 to 4 times a week.

29:42

Okay. So most lives take, depending on how complex

29:43

the handle scales are and all that stuff,

29:48

it's your knife probably took 8 hours.

29:52

All right. Most kitchen knives will take 9

29:52

to 10 hours with a very simple one piece

29:57

handle. If I have to do, if there's a bunch

29:57

of inlay work excuse me, multi base handles,

30:04

all that stuff, there's extra time with

30:04

getting everything to meet up really tight.

30:11

Extra glue, uptime, all that kind of stuff.

30:15

So if I was full time, I'd be able to do a

30:15

lot more and build up an inventory because

30:19

I'm part time. I do predominantly custom

30:19

work, so.

30:26

When I start my month, I already know the

30:26

knives I'm making and who they're going to.

30:32

I had an opportunity back in September to do

30:32

a motorcycle show.

30:37

So my entire month of September, all the

30:37

knives I made went to that show.

30:43

More to get a little more face time with

30:43

people that I normally normally wouldn't see

30:50

my work more than anything else that's.

30:56

The entire goal of that was just to do that.

30:58

But. To go back to your question.

31:02

If I had more time, I would do a lot more

31:02

shows than I do.

31:05

I just don't. So it's I'm almost always

31:05

doing knives for a specific customer.

31:13

And that's pretty nice that you don't have to. I mean, the shows, in my experience is like

31:15

I'm going out looking for customers where in

31:20

your situation your customers are already

31:20

lined up and it's just, okay, this is when I

31:23

can get to it. And you kind of are in

31:23

control of your schedule more than just

31:27

trying to build up inventory and hope it sells. It would be great if.

31:32

Right now, I'm getting a little nervous

31:32

about what I have on the books as I'm like

31:37

six months out, which for me is a little

31:37

light.

31:40

I get usually every month I add about 5 to 6

31:40

people onto my custom book.

31:46

I haven't been doing that recently.

31:49

Instagram's been a little things have

31:49

changed.

31:52

They've changed their algorithms a lot. It's affected me personally.

31:56

I don't know why, but things have slowed

31:56

down for my I might not be doing a great job

32:02

with Instagram, you know, I don't really

32:02

know what I'm doing.

32:07

I'm in the same boat, you know, I just. You try something. See if it works.

32:10

If it does, I. Just keep throwing baloney against the wall

32:11

and hope. That's I think that's what a lot of us do.

32:16

And it's, you know, talking to other people

32:16

and seeing what their experiences are is the

32:19

only thing that kind of helps. Like, okay, are you seeing other people's

32:20

posts? Some people do really great jobs with their

32:21

photos and they're laid out really

32:26

professionally and natural light. I've been trying to use artificial light and

32:28

I don't think it does quite the same job as,

32:31

you know, a good golden hour shot.

32:35

I most of my stuff's actually artificial

32:35

light.

32:38

And then the only time I have time to use

32:38

natural light is on the weekends.

32:45

Usually by the time I'm out of work, it's

32:45

especially this time of year, it's getting

32:48

dark. But I use a lot of what are these

32:48

things called, these big silver reflective

32:55

lights. Oh yeah. I use a lot of that and I just kind of hold

32:58

them where they need to be and move them

33:02

around and put white T-shirts on them to

33:02

help make the light a little less abrasive.

33:09

That's my cheat. That's my tip for you. Put a white shirt on it and I'll use it and

33:11

soften everything.

33:17

So, you know, given that you kind of have.

33:20

Just anybody contact you about knives and

33:20

you have this custom book.

33:24

How do you how do you schedule your time as

33:24

far as how much you can do a day or how long

33:30

it'll take until it's ready? It What it takes.

33:34

What it takes till it's ready. I don't. I try to do.

33:40

One month batches. So whatever I can think, whatever I think I

33:41

can get done in a month, which is usually

33:46

about four knives. Right now I'm doing seven, but that's all of

33:47

my stuff leading up to Christmas.

33:51

So there are all of my. I do try and give a little usually.

33:57

So usually I don't move my custom book

33:57

around.

34:01

But when it's a specific, this is a gift for

34:01

Christmas, blah, blah, blah.

34:07

I try to adjust to accommodate that.

34:09

It's kind of the only thing I accommodate

34:09

for.

34:12

I do cheat a little bit now and again, but

34:12

Christmas is the big one that if you let me

34:17

know ahead of time, I kind of like I'll make

34:17

a note in whatever.

34:22

But usually it's I try to do for a month, so

34:22

I know that I can get for a month done.

34:27

And really I spend as much time in my shop

34:27

as my wife can put up with kids on her own.

34:33

Right. And that's usually.

34:37

I really push it in my wife's friggin st, so

34:37

I usually do about 3 hours a night.

34:46

Wow. Four days a week. So that's 12, 12 hours.

34:51

And then if it gets really hectic and like,

34:51

I was sick two days this week.

34:56

So I worked a little bit last night, which I

34:56

probably wouldn't have done.

35:01

And I'll work tomorrow to kind of make up

35:01

for it to.

35:06

I'll put the Eagles game on the radio

35:06

instead of sitting on the couch and having a

35:10

bourbon, you know. You can still have the bourbon, just maybe no

35:12

couch. No, I think I just ran out of cord.

35:18

My last one. Maybe I'll send my wife out.

35:21

We'll see how. So what do you think?

35:28

Like once you decide to kind of take this

35:28

knife making into a business, what was, like,

35:34

the. The most bang for your buck that you

35:34

got where you started to see, like, some

35:38

success with it. Was it Instagram? Probably like you really

35:41

started to get your name out there more?

35:45

No, it's all been word of mouth.

35:47

Word of mouth really been the greatest thing

35:47

for me.

35:50

Okay. People.

35:53

The big honestly, the biggest thing was when

35:53

I started doing kitchen knives, to be quite

35:56

honest. Okay. The. Like the hunting community.

36:04

And it's been it was just kitchen knives.

36:08

I mean, really just was everything was

36:08

really kind of slow going.

36:14

Very word of mouth at the beginning. And then when I started doing Chef Knives

36:16

and started opening into that role, people.

36:21

People love cooking. So that really opened up.

36:25

People want to spend time with their. Everybody has their their family traditions

36:27

all revolve around remembering spending time

36:33

with their mother or their grandmother or

36:33

their father or their brothers or their

36:37

sisters or whatever. But it's always in the kitchen. So when. Once I started opening up and doing

36:39

kitchen knives and cutlery.

36:47

People tend to be a little more

36:47

understanding about wanting to spend money on

36:54

something that they're going to enjoy.

36:57

With one of the bigger parts of their lives,

36:57

which is cooking.

37:02

So that was really the biggest thing for me,

37:02

was everybody.

37:06

Everybody really loves looking at knives,

37:06

but most people.

37:11

I pull out a small fixed blade knife at a

37:11

party and people are a little like, Whoa,

37:16

bro, you show somebody a kitchen knife that

37:16

is way bigger and should be way of scarier.

37:25

They go, Oh, that thing is so cool, you know?

37:28

So like, it kind of took some of that.

37:32

Uh. I don't know that like the West Side

37:32

Story Switchblade stigma out of it, right?

37:42

I remember the first party I went to after I

37:42

started making knives and carrying my own

37:46

knives. I was like, Oh, I heard you're

37:46

making knives.

37:48

Let me see it. And I'd pull it out like,

37:48

Whoa, bro.

37:50

Like, that's huge. It's really not that big.

37:53

It doesn't fold. Right. But the moment you put that in a kitchen

37:55

context, people are a lot more accepting of

38:00

it and excited about it. Thinking about what? Like, I'm a big onion

38:02

guy.

38:05

I love cutting onions. I'm not a great cook. I'm actually very

38:06

shitty at it, but I love cutting onions.

38:11

The process of it is just so fun. So like, I always think about that, like,

38:15

Oh, this thing's going to cut an onion.

38:18

Great. That's the big you do.

38:21

You posted a video, I think, of cutting an onion. And I never saw anybody cut an onion.

38:26

And the way you did, is that your own style

38:26

or.

38:29

You know, that's actually the way you're

38:29

supposed to cut.

38:31

That's a big source of contention in our

38:31

house, dude.

38:35

Careful. Sorry. My wife gets. I get so mad at my wife.

38:39

What's wrong? Now, if you talk to a chef,

38:39

that's the.

38:43

The proper way to cut an onion is though

38:43

you.

38:48

Let's see. I'm trying to think without

38:48

having an onion.

38:50

So you cut. You cut the bud off that little root ball.

38:54

You kind of have the root ball down here.

38:57

You cut that off, you stand it up so that

38:57

whatever the turnip end is sticking up here,

39:03

cut that down the middle. You have two halves that grow skin off the

39:04

outside, lay it flat with that turnip and

39:11

stick in here. Cut it. One, two. No, I'm sorry.

39:14

Cut it. One, two, three.

39:17

Cut it this way and I just bump, bump, bump,

39:17

bump, bump all the way up to that heel.

39:22

And you'll have little. Teeny little squares, nice little cubes.

39:27

My wife refuses to do it. She cuts it however she wants, and I love

39:28

her for it.

39:32

That's I need to try that way because I saw

39:32

you do it the one time when you posted that

39:35

test and the. One show you. So I worked in kitchens when I

39:36

was in college and that's I got screamed at

39:42

for it. And I mean, they beat it into my

39:42

head.

39:45

That's how you cut and you get the most

39:45

yield out of it.

39:48

That way there's a lot less. There's a lot less that you can't cut up if

39:54

you cut it that way.

39:58

So that's the reason for doing it that way.

40:00

Okay. Now. My wife cut some clean in half and cut some

40:02

clean in half and then praise the God.

40:08

There's onions at the end of it. Yeah. I don't even think I have a method

40:09

other than just try and make it smaller.

40:14

Next time you're around, just come over. I'll say nothing. And really, I'll.

40:18

I'll post the video later. Awesome.

40:22

And then I'll tag my wife in it and maybe

40:22

she'll learn.

40:27

You're just. You're picking fights now. Living on the edge, dude.

40:33

What's your. So what's your favorite part of

40:33

the whole knife making process, including the

40:38

sale? Everybody loves the handles.

40:41

Yeah. When you get done that, that's.

40:44

You're really finishing the knife, then

40:44

putting the edge on it is making the thing

40:48

cut. But when you get the handle done,

40:48

that's when everybody like, Oh, my God,

40:53

that's so cool because. The performance part

40:53

of a knife is the bevels.

41:01

And what we were talking about this area,

41:01

right, how properly that's grown, that's

41:05

that's really what makes a knife cut

41:05

properly is.

41:11

As Senators, you can make that edge be.

41:14

And as consistent this side is to this side

41:14

of your bevels.

41:19

All right. So the tighter your edges.

41:23

As centered and straight as that edges, and

41:23

then your bevels being really consistent

41:27

makes an edge, a knife cut. Well, but everybody looks at a handle.

41:31

That's what sells the knife, right?

41:33

So if you're going down a knife show to a

41:33

knife show and you're looking at all the

41:40

knives on the table, the coolest looking

41:40

knife is the one you pick up.

41:43

You don't pick up some drab looking knife

41:43

unless it was your specific grandfather's

41:49

knife. You're not picking it up. So that's what sells the knife.

41:53

Finishing handles really is fun because

41:53

that's when all of the work you put in kind

41:57

of comes together. And this is going to be a

41:57

cool knife.

42:00

But I really have loved grinding knives

42:00

lately, getting edges really tight, knowing

42:07

how well they're especially culinary knives.

42:10

I really love grinding culinary knives

42:10

lately.

42:12

It's weird. It's a very it is not a very Zen

42:12

guy on the surface.

42:19

At least I guess a lot of my friends will disagree. Our friends, Chloe and Jason will totally

42:22

disagree with you, but.

42:25

Or disagree with me really. But that has become this very like try and

42:27

push that edge as tight as I can get it and

42:34

really think about how it's going to go

42:34

through food.

42:37

And the weird man. That.

42:40

Our favorite part is has become putting

42:40

bevels on knives.

42:44

Love it. So and it's so unrewarding because

42:44

I got to go take all those scratches out with

42:49

sandpaper, which if your next question is my

42:49

least favorite thing.

42:53

You got. It. And sanding bevels.

42:56

And that's what sandpaper. It's sandpaper.

42:59

So after I grind bevels in and this knife

42:59

hasn't been hands ended because it's been.

43:07

The belts that I used were a lot finer and

43:07

EDC knives are a little easier to finish.

43:14

So after you grind your bevel here,

43:14

especially on culinary knives, you want to go

43:19

through and hand sand out. All the big scratches.

43:24

Right. Because what happens is water,

43:24

alcohol, water will collect in those

43:31

scratches, collecting the scratches, and

43:31

you'll get deep rust marks that you can't get

43:35

out because there's these deep little

43:35

scratches and it's just the nature of the

43:40

beast. So what you have to do is sit there

43:40

and hand sand hardened steel, which sucks.

43:46

It's way worse than it sounds. And it sounds horrible. So imagining sanding

43:48

a block of oak.

43:54

Sucks. Takes time. Once you're done, you're done.

43:57

And you're you probably going to 220 Grit.

44:01

Maybe for if you're trying to make a really

44:01

shiny thing on a knife, you're going to 800.

44:08

Okay? And you have to go through every

44:08

single grant and you have to get them every

44:15

single scratch from the previous grit you

44:15

have to get.

44:17

It sucks the worst. Sorry. That's all sucks.

44:22

One more question before I torture any more

44:22

with it.

44:25

So once you're done grinding, when you start

44:25

that hand sanding process, you start with

44:29

like 200 and get it down, then 400 and get

44:29

it even finer.

44:32

And you're slowly just stepping it down to

44:32

make the scratches smaller and smaller.

44:37

Step one Yeah, that sounds like it sucks.

44:40

Mm hmm. Yeah, it's usually. I'm really bad about it.

44:43

It should take about an hour and a half a

44:43

knife.

44:46

It usually takes me about an hour and 45

44:46

minutes to 2 hours.

44:50

Okay. So that's just hand sanding the levels of the

44:51

knife.

44:56

That's nothing else. But like you said, that's going to affect the

44:58

performance. That's it doesn't it doesn't affect the

45:00

performance and it's just gravity in the

45:05

knife. So if you have all those scratches,

45:05

you'll get rust marks.

45:09

And if those rust marks keep developing, you

45:09

get deeper and deeper rust in the knife.

45:15

And that rust is. Rust is everything.

45:19

Biggest enemy. Cars, knives, motorcycles.

45:23

All the cool stuff. Rust is bad to. It is true. I've never seen Rust be looked at

45:27

in a positive light over.

45:32

Unless it was a color of something.

45:36

That's really cool. It's it's so much work

45:36

that goes into, you know, such a simple tool

45:41

but is so beautiful in the same respect.

45:45

Would you have any advice for somebody that

45:45

was like, Yeah, I want to learn how to start

45:48

making knives? Totally do it. Yeah, but just be totally.

45:54

It's just like any craft. Like, if you really want to do it, suck it

45:55

up.

45:59

Be. Be ready to know your first name is

45:59

going to be a piece of garbage.

46:06

Mine. Mine is total junk.

46:08

I'll post it later so you can see it. It's a piece of shit.

46:15

It's just. It's another craft. So be willing to fail.

46:21

Absolutely. Is there something that's worth spending more

46:24

money on?

46:27

Like, I know it's you don't always have to

46:27

spend money on the best tools.

46:31

Grinder. Good grinder. Really good. A two by 72 grinder with

46:32

variable speed.

46:36

So variable speed changes.

46:41

So it's a bell grinder. So you have a here

46:41

is a one by 30 inch bell.

46:47

Okay. One inch wide, 30 inches in circumference.

46:55

Variable speed means that that belt goes

46:55

around slower or faster and you have

47:01

unlimited. It's a dial. So you change that dial and it goes fat

47:03

really fast.

47:07

Not so fast. It is ultimately variable.

47:12

Right. And that really helps.

47:15

That's the the best thing I ever got.

47:17

My I have a buddy out in Audubon that made

47:17

it.

47:22

When I made The Grinder. Yep. Oh, yeah. Smart student, hands down.

47:27

The smartest person I've ever met. Is that something he does commercially that

47:29

other people could purchase?

47:31

Or. I was just. No, he made it for himself.

47:35

He doesn't make knives anymore.

47:37

He made, like, I don't know, 20 or 30 knives

47:37

and.

47:44

He doesn't use it. He knew I would use it.

47:47

He gave it to me. I keep kind of giving them

47:47

money every now and again for it.

47:51

Nice. It's a really bad ass tool.

47:54

There's a lot, but there are. There are commercial outfits that make them.

47:58

They're like. They're not cheap.

48:01

They're worth it, though. But. They're not worth buying unless you're

48:03

going to look for a new maker.

48:10

Don't buy it. Buy a $100 harbor freight one.

48:15

Most of my knives that I made in the early

48:15

days were on on one by 30, I think it was a

48:20

harbor freight, $100 belt grinder.

48:24

You can buy belts for it. You can figure out if you like it or hate

48:26

it.

48:29

It's a craft. There's plenty of suck to go

48:29

around to learn it, but oh yeah, if you love

48:35

it, you love it. But it's just like any

48:35

craft, you have to be willing to fail.

48:41

You have to be willing to learn from your failures. And if you decide that it's worth learning

48:45

from, then you're going to love it.

48:50

If you think that the failures suck and

48:50

they're not worth learning from, then go find

48:54

something else. And that's totally fine. But it's just leatherwork.

48:59

Burnishing edges on leather.

49:01

Yep. Is a nightmare. It looks awesome when it's done, but it's a

49:03

nightmare to get to.

49:07

But once you realize that you love doing it

49:07

like the once you realize them products worth

49:12

it. Then you love it.

49:15

And then that's what you that's you're

49:15

always seeking that perfectly burnished edge.

49:20

Yeah. And that's that's a search I'm still on

49:20

because I see some of these guys post stuff

49:24

and it's. That's why I don't do leatherwork because I

49:25

don't fucking care.

49:29

It is at all tedious.

49:32

Super tedious. I use a belt grinder to get to like 600 grit

49:33

and then I go that close enough, I'll cover

49:38

it and wax. They do have those edge coatings, I think

49:40

kind of again, you know, if you're a purist,

49:44

maybe, yeah, it's some people might think.

49:46

It's not a leather work. That's why you got to get that.

49:49

You got to get started getting this. I know. I need to get that a couple more.

49:53

I think I got the pattern down. It's been a lot of fun.

49:56

I don't want to do them anymore. So, Huck pull and thread is.

50:01

Yeah, it's not for me. See, I'm weird too. I enjoy it.

50:05

Oh, yeah. I really appreciate your time.

50:09

I know we're getting close to the end here. Is there anything else you wanted to talk

50:11

about? Nyfw wise or business wise?

50:15

If I had business advice, I'd give it to

50:15

myself.

50:21

I mean, it helps pay the bills for me, but

50:21

now I got nothing, man.

50:28

That's cool, man. Jesse, I really appreciate it. It's been fun learning how you kind of

50:30

create these knives.

50:32

I use mine every day. I'm glad to hear it. Dude.

50:36

I might have to pick up one of those chef

50:36

knives, because.

50:41

Whenever you're ready, I just love to hear

50:41

that they go out into the world and get made.

50:46

That's a big the biggest thing for me is the

50:46

worst thing would be knowing I made something

50:51

and nobody gave a shit about it that would

50:51

that would make the time.

50:57

Kind of depressing. Yeah.

51:00

You know, like. Oh, it's a knickknack that I

51:00

threw in the drawer, you know, like, I don't

51:05

want my stuff in with your batteries.

51:08

And it's not. Not getting a good story develop that way.

51:11

Your Chinese food menu.

51:14

That's not where I would like to think that

51:14

my stuff's a little higher quality than that.

51:21

Oh, I would agree. It definitely is. Thank you. I appreciate that.

51:26

Yeah. Yeah. I don't know. It's it's a craft.

51:29

It's it's all supposed to be done with love.

51:32

That's that's the idea anyways.

51:35

It is. And that's what I've seen.

51:37

And I think it shows in all the products and

51:37

that's why I enjoy and kind of wanted to

51:41

reach out and talk to other Pennsylvania

51:41

makers to get a little more inside in their

51:45

story and then what drives them. And there is that baseline of pride that I

51:47

think we all have where you love what you do

51:52

and it goes into it and seeing somebody else

51:52

enjoy it, too.

51:55

Is it's really fulfilling? Yeah. Oh, absolutely.

51:58

And I really appreciate the time you put on this. This means a lot.

52:02

Yeah, man, this has been fun. I will definitely link to your website and

52:04

your Instagram and the show notes and give

52:09

people a way to contact you so they can get

52:09

on the books and get one of these awesome

52:12

knives. Oh, no. If anybody wants any further

52:13

information on learning how to do it.

52:18

I'm a jackass, but I'll point in the right

52:18

direction anyways.

52:22

That's all it takes. You ought to know the answer. Just know who does.

52:25

Exactly. Awesome. Thanks again, Jesse.

52:28

All right. Josh. Thank you, dude. Take care.

52:30

You too, buddy. All right. Thanks for listening to this

52:35

episode of Handmade Pennsylvania.

52:38

You can find more information from this

52:38

episode in the show notes at Handmade

52:43

Pennsylvania. Please like the episode and

52:43

follow the podcast.

52:48

It helps us be found and helps these makers

52:48

spread their craft and their business.

52:52

It really means the world to us. All right, guys. Until next time.

Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

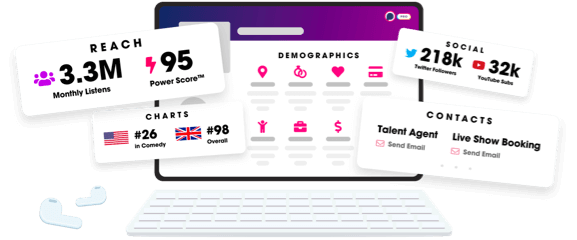

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us