Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:01

Hey

0:04

yo, this is the HVAC School Podcast. I'm

0:06

Brian and I'm still sick. This

0:09

is like the longest sickness ever. Anyway, you're

0:11

not worried about that. Today we're going

0:13

to be talking about motor protection,

0:16

overloads, overload types, because it actually does matter

0:18

and it is the sort of thing that you're going to

0:20

need to think about especially if you're used to working on

0:22

one type and then you go to a different type and

0:24

you're going to notice that there's some variation. So before

0:26

we do that, we're going to thank our great

0:28

brand partners, Fieldpiece, fieldpiece.com

0:33

and specifically the SR-47 wireless

0:35

refrigerant scale, the new heavyweight

0:38

champion of digital scales. Refrigeration

0:41

technologies at refrigeratech.com,

0:44

carrierandcarrier.com, navac

0:47

at navacglobal.com. All

0:52

right, so the most common type of

0:54

overload that you are used to if

0:56

you work in residential is

0:58

an overload that is built into a motor,

1:01

your condenser fan motors, your blower motors,

1:03

and most specifically your compressors, and

1:05

that overload is a thermal overload. So

1:08

it's a bimetallic disc, generally speaking, usually

1:11

pretty small, and they're usually positioned

1:14

in the windings directly behind the common

1:16

terminal on a PSC type motor. Now

1:19

that's again, the PSC type motor. So

1:22

you're not talking about inverter driven, you're not talking about

1:24

ECM, this is just the basic type of motor that

1:26

we've worked on for years. And

1:28

what happens is when that

1:30

motor overheats due to a locked

1:34

condition or some electrical problem

1:36

or just regular old overheating,

1:38

maybe that motor is running hot because it's

1:40

low on charge in the case of a

1:43

compressor or it's in an

1:45

environment that it wasn't designed for. Maybe

1:47

it's running too hot because it's just in a super high

1:49

ambient condition that it was never designed to be in. It's

1:52

going to open that circuit and

1:54

shut off that motor. So

1:56

that is a thermal overload that is a bimetallic

1:59

Disc. The middle desk and thereby metallic

2:01

overload was very simple. It just has

2:03

to different types of metals that's the

2:05

bimetal part plastered on to each other

2:08

and so they have different expansion and

2:10

contraction rates. And. At a

2:12

certain temperature it's designed to open up,

2:14

a dick flexes and it opens the

2:16

circuit and then once it gets back

2:18

to a certain temperature than it's going

2:20

to close and and cause the circuit

2:22

now any sort of by metallic. Overload

2:25

if it's used to. many times. if it

2:27

opens and closes too much, it eventually can

2:29

fail. And. That's mostly because the Arcane.

2:32

But. Also because it is made of physical

2:34

materials right in this is ago materials when

2:36

they open and close and of times you

2:38

can actually cause it to stay open, stay

2:40

stuck. open. Or. And some

2:42

rare cases it may not open when it's

2:44

supposed to. That is can be much more

2:47

rare. But either way, they're not designed for

2:49

switching duty. They're not designed for operating the

2:51

motor on and off. When this

2:53

is where you'll get cases where people say why would a

2:55

motor has an overload and it. So.

2:58

That's gonna protect the motor will yeah,

3:00

but if the system has inappropriate charge

3:02

and enters gonna restriction or something and

3:04

that's causing. Maybe. Hi discharge

3:06

temperature I compressor temperature over time it's can

3:08

still have issues still gonna break down the

3:10

oil and still going to damage the compressor

3:13

and so it's not a good thing to

3:15

be operating on that overload. But. That's

3:17

what a thermal overload does. so uses

3:19

temperature. That's the term there. It's an

3:21

overload that uses temperature thermal in order

3:24

to open the circuit. a project motor.

3:27

In. Fact: A lot of circuit breakers actually

3:29

work with this same thermal design, so

3:31

they actually have a thermal overload inside

3:33

of them so that when they heat

3:35

up that's what causes and the trip.

3:37

And you'll find often that most of

3:39

your inexpensive circuit breakers you're going to

3:41

have more likelihood of nuisance trips during

3:43

really hot days they need you and

3:45

other conditions. As also because often the

3:47

equipment is also running higher compression ratios

3:49

and so the compressor dry, higher current.

3:52

That's. Also a reason, but it's just because

3:54

hire a being conditions if you're using

3:56

a thermal limit. Is can be more

3:58

likely to trip. under high ambient conditions

4:00

because it's already when

4:04

it gets to that warmer temperature. And

4:06

so you'll see that hot summer days, you're

4:08

going to be more likely to have nuisance trips or

4:11

breakers than you do on cooler days. But

4:13

that is not true with magnetic

4:15

overload devices. So if you've worked

4:17

in commercial and you've seen a starter, there's a

4:19

lot of motors that do not have overloads built

4:21

into them in commercial. They actually

4:23

rely on an external overload. In fact, you'll

4:26

even see this in some small refrigerators. You'll

4:28

have an external overload actually

4:30

built into the electrical box

4:32

on that compressor. There's not one

4:35

inside intrinsic to the compressor. It's actually

4:37

outside in that little thermo disc sits

4:40

on the outside of that compressor. And

4:42

that would be an example of an external thermal

4:45

overload, but an external magnetic

4:47

overload is very common on

4:49

larger motors. And that is often

4:51

integrated into your contactor and whatever

4:54

turns that motor on

4:56

and off. And that is called a starter.

4:58

So when you take a contactor and you

5:00

combine it or switch gear and you combine

5:02

it with an overload, they call that a

5:04

starter. And so built in, it's going to

5:06

have in some cases preset, but in many

5:08

cases adjustable overload settings. And it's going to

5:10

be based on current, not temperature, which is

5:12

a much more accurate way to really measure

5:14

overload on a motor. Whereas with

5:16

a thermal limit, it's going to trip based on

5:18

overload conditions electrically, meaning drawing too much current, that

5:21

kind of thing locked. But it's also

5:23

going to trip just because that motor itself

5:25

is running too hot. Whereas magnetic

5:27

overloads aren't going to do that. It's just going

5:29

to do it based on current, which

5:31

that is easier to control. It's easier to set,

5:34

but it does run the downside that if that

5:36

motor is overheating for another reason, that

5:38

magnetic overload is not going to protect

5:41

for that. I'll give a common example.

5:43

Like you go to a compressor and

5:45

regular residential and that compressor has an

5:47

internal thermal overload. A lot of

5:49

times that thermal overload will be tripped because like we said,

5:51

it's low on charge and it takes you a long time

5:53

to cool that thing down in order to kick

5:56

it back on again. Whereas If it

5:58

was a motor that did not have an internal thermal overload, Hello

6:00

thermal overload and instead had an external magnetic

6:02

overload. It would be much easier to get

6:04

that motor running again. You wouldn't have to

6:06

go through that whole process of call me

6:08

everything done. Is that a good thing? Is

6:10

it a bad thing? Will It really just

6:12

depends? It depends on the situation. Like I

6:14

just mentioned, it's nice to not have to

6:16

wait forever. But it's also not great because

6:18

if there's another condition that's causing that motor

6:20

to overheat, that's not just current overload, than

6:22

that is a protection that you might be

6:24

missing. Now again, as you get into bigger

6:27

motors, dancer, compressors off, and you're going to

6:29

have multiple redundant systems. See may

6:31

have a separate thermal system, temperature system,

6:33

the to me the compressor completely separately

6:35

with sensors electronically so forth, but. What?

6:38

We do very simply with

6:40

thermal overloads and very basic

6:42

pieces of equipment. Sometimes we

6:44

do redundant Li with different

6:46

controls and more complicated systems

6:48

and this magnetic overload is

6:50

very common. You also are

6:52

going to see magnetic overload

6:54

circuit breakers at times, so

6:56

a good example is Square

6:58

de Que Lo. In

7:01

a lot of houses you will see

7:03

square de que lo circuit breakers. Those

7:05

are magnetic trip circuit breaker so they

7:08

are less impacted by the thermal side.

7:10

They're less impacted by temperature because they

7:12

are based on current and so because

7:14

of that they tend to trip more

7:17

consistently at a given current Because they

7:19

are a magnetic or current based overload

7:21

device. you're also going to see a

7:24

couple different types of their mister based.

7:26

And. Through mister based overloads, the

7:29

simplest. Is to use a

7:31

P T see positives your coefficient

7:33

there mister. In. Series with whatever

7:36

motor you're controlling and how that works

7:38

is. With. Beauty see the hotter

7:40

it gets, the higher the resistance

7:42

of that Ptc as after Mr

7:44

is just a resistor that changes

7:46

it's resistance based on temperature. Positive.

7:49

Temperature coefficient just means. That. As

7:51

temperature goes up. Resistance. Goes on

7:53

and so effectively if it gets hot enough and

7:55

again depends on the design of his resistor and

7:58

has to be designed in the specific range. That

8:00

you need but as a temperature goes up.

8:02

That. Resistance goes up. Where's that? Resistance gets high

8:04

enough? It can effectively just completely take that winding

8:07

out a can of. Since he said the motor

8:09

off. Because as resistance increases, current decreases

8:11

and it'll just set it off completely. Slutty,

8:14

Ptc. But. They also have set

8:16

ups were you use and Ntc Ntc to mister.

8:18

So in that case what would happen is it

8:20

would be a separate circuit. It wouldn't be in

8:23

series. It would be a separate parallel circuit with

8:25

a relay. And as it

8:27

gets hotter, that motor gets hotter,

8:29

the resistance decreases. Which. Then

8:31

allows it once it gets low enough, allows

8:33

it to pull in a coil which then

8:36

opens the circuit in shuts the motor off.

8:38

Now that was too confusing of a sentence.

8:40

don't worry about it. The source

8:42

and you normally see and wiring diagram

8:44

but the point is sometimes we directly

8:46

used to misters either Ptc you're in

8:49

T C in order to act as

8:51

overload protects and some Snc directly. Using

8:53

that characteristic of semesters were resistance changes

8:55

which changes in temperature and order to

8:58

protect motor. And the final

9:00

categories to say a wide range of

9:02

different electronic controls and any to use.

9:04

Thera couples their misters that report back

9:06

to some central digital control which then

9:08

also acts as protection and that's I

9:11

was talking about an you bigger more

9:13

complicated devices nowadays years since difficult sellers

9:15

of sorts of things you're going and

9:17

to the have centralized controls that are

9:19

going to help protect. Those. Devices

9:21

That doesn't mean that you're not still going

9:24

have your basic magnetic overloads or other types

9:26

of overload protection, but it does mean. That.

9:29

You're often gonna have some form of redundancy

9:31

and really use always looking at two primary

9:33

things. You're. Looking at current. Or

9:35

he drank too much current need to shut it

9:37

down because of that. Something's locked up or it's

9:40

not running efficiently are bound up. Whatever. There's

9:42

a mechanical problem that's causing it. And.

9:45

Then second thing that we could be is

9:47

temperature says something's overheating and that's where you

9:49

can use to mister a couple seconds to

9:51

measure but the three basic types. Most.

9:54

Common or thermal overloads. Than.

9:56

A magnetic overloads and then using.

9:59

A. there Mr. Based Protection Device.

10:02

Alright, hopefully you found that helpful. I'll

10:04

talk to you next time on the

10:06

HVAC School Podcast.

Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

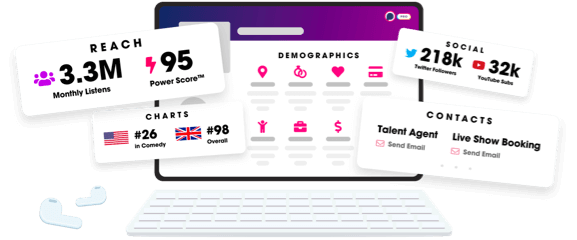

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us