100 years ago, rice farmers near Songhkla, Thailand would send their freshly-cut rice to the Red Rice Mill to be processed for sale. Rangsi Ratanaprakarn’s father ran the mill and raised his family across the street. The following is an excerpt from his short autobiographical book, Growing Up at the Red Rice Mill, featuring stories from his childhood. The artwork is by the amazing Malaysian artist, Kiah Kiean Chng at KaKi Creation in Penang.

You can DOWNLOAD Mr. Rangsi's e-book for free.

"My father loved this place so much. I want to keep it to now hand it over to my children. Because of the Red Rice Mill, my father and our family had a good life. I could go canoeing on the lake. Learn to drive a car. I went go to college. All the stories I told you. Later I started my own company and have travelled all around the world. This was all made possible because my father and mother worked hard - and because of the Red Rice Mill. I learned from my father the importance of a good education, working hard, and of helping other people."

"I remember walking into the rice mill. They burned rice husks to heat the water boiler. The smoke went up the stack but because of the turbulence in the air, you could smell the smoke throughout the rice mill. It didn’t smell bad - not like burning plastic today - but it wasn’t very pleasant either.

The Red Rice Mill is four stories tall. You can see lots of very small, square windows on the outside. They were built for ventilation. Back when the mill was in operation, there were people who worked on each floor. Their job was to make sure the belts and pulleys connected to the steam engine worked correctly. But it got hot inside, so they could open these windows and the air would come in and cool them down. There wasn’t any electricity so the windows also provided light.

In the morning, my father would leave the house and walk across the street to the mill. He’d go through two small doors, now to the right of the Songkhla Heritage Society’s glass office.

Right from the beginning there was a mistake in the design of the rice mill. The smoke stack you see today looks so nice, but it was never used. When my father’s uncle designed the rice mill, he ordered a steam engine from England. Before it arrived, he decided to go ahead and build the smoke stack they would need to attach to the boiler. That way, when the engine and boiler arrived, they could get started right away. They imported high quality bricks from India for this first smoke stack. It was a good idea, but for some reason, the Chinese carpenter didn’t read the plans correctly. The first smoke stack was built in the wrong place. They put the boiler and engine on the other side of the rice mill. That meant that they then had to build another stack so they could get a draft to the boiler. This second stack was the one they used for so many years, but it was made from cheaper, local bricks. It wasn’t as strong as the first stack made from bricks imported from India. So after the steam engine was no longer needed, they decided to dismantle the second stack. They thought the cheap bricks would be too dangerous to leave up, so it was dismantled. The smoke stack you see today was the one made from Indian bricks, the first stack, which was never used.

The breeze would come about 6 or 8 months a year. so it helped to blow and send the draft through the boiler and through to the stack. The boiler and engine were set up on the other side of the rice mill. In the corner, there was a boiler. With a fire, they boiled water which powered the steam engine. The steam engine turned one big wheel. From this one wheel there were many pulleys running throughout the rice mill. This was how they ground the rice. Today you can still see many places where the pulleys and belts ran. The roof in the main hall was much lower than now. Then in 2491, this area (the old roof) was demolished and rebuilt in concrete.

From The Podcast

OXLAEY Cultural Heritage Travel Magazine PODCAST

OXLAEY is a cultural heritage travel magazine. We tell stories about singers, painters, poets, craftsmen and craftswomen, as well as traditions and religious rituals. At www.oxlaey.com you can find videos, music, articles and subscribe to our print magazine!Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

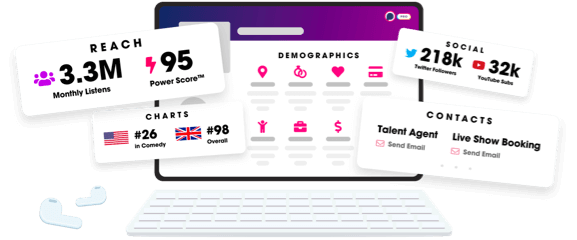

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us