Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:03

My trading partner comes to the planning

0:07

table, if you will, just like an internal

0:10

stakeholder. So that synchronises

0:13

that aspect, which used to be kind of

0:16

arm's length away. I may share a

0:18

spreadsheet over email and then

0:20

wait for response in a in a week.

0:23

That doesn't work anymore. It needs to be real time.

0:28

Good morning, good afternoon or good evening wherever you

0:31

are in the world. This is the Digital

0:33

Supply chain podcast. The number one podcast

0:36

focussing on the digitisation of Supply chain.

0:38

And I'm your host, Global vice president of SAP.

0:41

Tom Raftery. Hi, everyone, welcome to

0:45

the Digital Supply chain podcast. My name is Tom Raftery

0:48

with SAP and my special guest on the show today

0:50

is David. David, welcome back.

0:53

Would you like to introduce yourself?

0:55

Thank you so much, Tom, for having me. Yes. David Vallejo

0:58

here, I lead solution management and go to

1:01

market for all of our Supply chain planning

1:04

solutions at SAP, namely integrated

1:07

business planning, which is a very

1:10

exciting innovation to rethink and

1:13

innovate supply chain planning in the cloud.

1:16

So I'm happy to be on your show. Thank you.

1:18

Thanks, David. Just for because we've

1:22

we've had a couple of conversations about this before and about

1:26

supply chain planning in particular. And it's a very grey area for

1:30

me. So just I know everyone else

1:31

listening to the show knows

1:32

exactly what you're talking

1:34

about. But just for me. Can you tell me what's

1:37

the function of planning in a supply

1:39

chain?

1:40

Yeah. So, so very interesting, because

1:43

I think it has a long history and it has

1:45

also evolved over over the years.

1:48

Fundamentally, what Supply chain planning does is essentially

1:51

connecting what I'm seeing as demand out

1:54

there in the market and connect it to all

1:56

the resources required to service that

1:59

demand. So it goes back to

2:03

to like the 70s or even back into the

2:06

60s, whereas things like mature

2:07

requirements planning were were

2:10

invented, which became then eventually part of of ERP.

2:15

And since then, it has evolved into

2:18

a very integrated

2:21

environment that is not just looking at

2:24

the logistics aspect of connecting the

2:27

demand to what needs to be produced, what

2:29

needs to be procured, but also integrating

2:32

it with the finance perspective.

2:35

What investments are unnecessary?

2:37

How does that look like with, from a

2:39

revenue perspective, working capital perspective and then

2:43

on all the different dimensions of supply

2:47

chain planning, adding machine

2:49

enabled capabilities, for example, to do a

2:52

better view of my demand plan, using

2:55

statistical methods, removing essentially

2:59

that human bias. What have I sold in

3:01

the past, projecting that into the future,

3:05

using techniques like different optimisation

3:08

and hueristic to increase the

3:10

efficiency of my production resources

3:13

of the material that I'm buying. Because what is

3:16

really, really expensive is inventory that is

3:19

inserted into the supply chain that is not needed.

3:23

So an integrated supply chain planning

3:27

brings all of these things essentially

3:29

together. And so we're very excited to

3:32

have a lot of companies around the world adopting these

3:35

solutions to essentially mature

3:38

their supply chain planning discipline.

3:41

OK, I think I got that.

3:45

So for, let's say,

3:48

a toilet paper company, the signal of a an

3:52

imminent lockdown might be a something that

3:55

they put into their planning to say "Oops,

3:58

there's going to be a spike in demand. We better

4:01

start buying up more recycled paper" or

4:04

change to, you know, say instead of selling

4:08

to hotels, maybe start selling to grocery

4:11

stores or something like that.

4:13

That's exactly right. So so you're introducing actually

4:16

an interesting point, which is the time

4:19

horizon of my planning. And that's really

4:22

important. There are aspects

4:25

what what we call strategic supply

4:27

chain planning. So that has a longer lens. I'm looking out

4:30

like two to three years to create

4:34

a plan that says, here's how much I

4:36

want to sell. Here are the resources

4:39

that I need. Maybe I need some investments

4:41

here, some new products that I'm introducing.

4:44

So I have to make sure that they are

4:45

introduced to not cannibalise

4:48

products that I already have. And then you're

4:50

getting into the more short

4:52

term horizon. We call this the

4:53

tactical horizon. So this is

4:55

more looking at like six months out.

4:58

And then now you're introducing the example why in

5:03

the recent few months this time, horizons

5:06

have essentially collapsed for companies, things

5:09

that happened over years in terms of

5:12

evolving demand or changing the channels

5:16

from, for example, shipping in bulk,

5:20

shipping directly

5:22

to to to other

5:25

businesses or distributors have

5:28

changed. All the sudden during the lockdown, I had

5:31

to react very, very quickly.

5:34

So that introduces this concept of

5:38

of that short term planning

5:41

being essentially embedded in my strategic planning,

5:45

meaning decisions that I'm making today.

5:47

You mentioned that, you know, toilet paper

5:49

company. They woke up overnight and all the

5:52

shelves were empty and toilet paper.

5:56

It is an example that has a really high

5:59

ratio of volume to price.

6:04

So that means it's very, very expensive to store because it

6:07

consumes a lot of volume, which

6:10

introduced actually the problem for these companies, because

6:13

normally toilet paper has a very steady

6:16

demand. OK, it's very predictable long term

6:19

how much is being consumed. So that is easily

6:23

then being disrupted. So it introduces

6:25

essentially the need for what we call

6:28

synchronised planning, connecting

6:31

that strategic planning long term

6:34

with the tactical mid-term, with the

6:36

short term, because what happens in the here and then now can

6:40

impact what I'm strategically trying to accomplish.

6:43

So that's one trend that we're seeing

6:46

that actually got amplified in the last

6:49

few months. There are other trends

6:51

that essentially influence the need

6:56

to be a more

6:58

real time and more synchronised in

7:01

your planning activity with what's happening

7:04

on the execution side.

7:06

Some companies have, like the consumer

7:08

products companies, think

7:11

about a more direct to consumer model. So that introduces

7:16

obviously now a consumer products

7:19

brand. I typically sell indirectly through

7:22

the retailers. I'm sort of taken a

7:25

back step. I'm shipping in bulk,

7:27

shipping in big volumes. Now I have my

7:31

my brand out there. I have a shopping

7:34

experience directly for consumers and

7:36

more intimate with them. But I also then

7:39

introduce a more diverse and complex

7:43

distribution models that are all the

7:46

sudden. I own myself. So that brings in

7:49

that planning what I'm thinking I'm

7:53

going to sell how much will be needed,

7:56

which is going to change.

7:58

Link that with my execution. How much

8:00

am I producing? How much am I

8:04

needed to load in my logistics? How many

8:06

trucks will I need? Where do I ship this?

8:10

So that's that's another example of

8:13

trends. The other trend is, I

8:16

think the timeliness, as I mentioned, Covid

8:20

kind of made us all realise that time is

8:22

collapsing. If I would ask you,

8:24

what days is it today? You would be

8:26

like looking at your calendar. I don't even know.

8:29

So that compression of time, the

8:31

expectation also for consumers to get

8:34

things in a very short amount

8:37

of time. Same day shipments

8:40

that. Something in the morning and it arrives at your

8:42

doorstep in the evening,

8:45

essentially changes the whole way we

8:48

think about planning, which is not just

8:51

articulate. How much will be

8:53

needed. How much will be ordered. And then weeks from

8:57

now. I that connects to how much I'm

8:59

producing, how much and my shipping.

9:02

It needs to be acting a lot more in a

9:06

synchronized way.

9:39

OK. I mean, you've you've used the term

9:42

synchronised planning now a couple of times

9:45

in the podcast. What do you mean by

9:46

that? And what does it mean

9:49

to link up your demand

9:51

to your execution?

9:53

Yeah, a great question. So. So typically I

9:56

introduced this concept of strategic

9:58

planning, tactical and operational

9:59

planning. What that typically

10:01

does is it is looking at volumes

10:06

by a certain time period. So, for

10:08

example, how much I'm not gonna

10:10

sell in week four, week five,

10:14

week six. And it's just using

10:16

one number because that number is

10:18

actually a lot easier to handle.

10:21

It's kind of the thought process of a more aggregator plan.

10:25

Operational planning then says, all right,

10:28

I'm now putting it into days. How much am I going

10:30

to produce next Monday, Tuesday,

10:33

Wednesday? And it's still

10:35

somewhat aggregated plan.

10:38

If you look actually into a factory

10:42

in a plant, they have to actually

10:45

look at shifts. They have to look at

10:49

detailed production lines that need to be

10:52

scheduled. So some large

10:53

companies are overseeing

10:56

potentially a hundred factories around the

10:58

globe. And every factory you

11:00

have production lines that have to be

11:01

scheduled. So execution actually

11:05

means being a lot closer to the actual

11:08

physical world and the intricacies that

11:10

are required to actually get things done.

11:13

That is what we call execution. So in on

11:17

the production side, we had a solution and

11:20

have a solution at SAP, which is called production planning

11:23

and detailed scheduling. What that does is

11:26

it's essentially opening the factory

11:29

door and look at the 30 different

11:33

production lines that are out there, the

11:35

jobs that have to be scheduled. The labour

11:37

that is required to

11:39

actually get these jobs completed.

11:43

It looks at the warehouse to pick the

11:45

material and issue it to the line.

11:48

So it's essentially every little

11:50

transaction that happens in order

11:53

to get from. I want to produce.

11:58

500 pallets on this day from the start

12:02

to actually finish it and everything that is

12:05

required. So that is the execution.

12:08

Environment planning traditionally has

12:10

been somewhat abstract from this.

12:14

So it just looked at how much do I want to

12:16

sell? And on a high level, how much can I

12:19

produce? How much do I have an inventory?

12:23

More on a kind of high level. And what we're doing

12:26

now and see that amplified with the

12:29

trends that we're seeing is connecting

12:32

these two worlds in a much more real time

12:35

fashion and also connecting it by

12:37

directly. That means back to the example.

12:40

I want to ship 500 pallets next Monday.

12:44

I'm putting that down to the factory.

12:47

I'm loading the lines. Can I accomplish this?

12:50

What does that mean in terms of

12:51

potentially change over maybe

12:54

these lines are already running some jobs

12:56

still from last week and getting that

12:58

feedback back and say,

13:01

is it possible to produce the 500?

13:03

Or do I have to adjust? Because if I do have

13:06

to adjust, I have to adjust my customer

13:08

commitments. I have to change

13:12

potentially my transportation plants, because if I

13:15

now have to produce this over two days,

13:18

well, then that means I have to reschedule the trucks that pick

13:21

in the subway. So it it shows you how this

13:23

is all actually connected.

13:26

And this is what we're accomplishing.

13:29

In SAP products speak, it's

13:32

connecting integrated

13:34

business planning, which is in the cloud

13:38

that accomplishes this, this demand

13:42

and supply matching and inventory

13:45

planning to production planning,

13:48

for example. And we've released

13:52

this recently with our August release to

13:55

have this bi directional connexion

13:58

and also harmonise this in one user

14:00

experience. So it brings up the

14:03

new topic also of different

14:05

organisational roles.

14:07

Okay, now that we have the ability to

14:10

have a demand

14:12

planner that looks more at high level

14:15

volumes across

14:17

the portfolio, across

14:20

a region, for example, to connect

14:22

this to actually what's happening in the factory brings the

14:26

ability to actually have some level of

14:29

supply chain convergence. Now, I can introduce,

14:31

for example, a production planner

14:34

that schedules the lines across multiple

14:37

factories. Because now technology

14:40

allows me to do this and I can rebalance

14:44

if I'm producing the same products across

14:47

multiple factories. I can make the

14:50

decision to produce it here versus here.

14:53

So it introduces a new level of

14:55

efficiency. It also enables

14:59

companies to run more sustainably.

15:02

Because in the end, you're not wasting

15:04

resources unnecessarily.

15:07

Nice, okay. Are there any industries that this

15:09

kind of thing suits more than others?

15:12

Yeah, that's a great question. There are certainly

15:15

for industries that also own

15:19

the execution part, meaning, for example,

15:21

companies that still they are doing their

15:24

own manufacturing. So consumer product

15:26

companies, chemical companies, oil and

15:29

gas companies, they're highly

15:30

connected with the

15:33

discrete products that they're selling with the

15:36

manufacturing process, which sometimes is

15:38

actually very process oriented. So you have

15:40

that convergence from from Prosser's

15:43

manufacturing into discrete goods that

15:47

I'm selling. There are other

15:48

industries where this applies,

15:52

not so much or in a different way.

15:54

High tech is a good example there. Most high tech

15:57

companies today are 100 percent

16:00

outsource their manufacturing with

16:03

contract manufacturers that have the ability

16:07

to produce for a lot of high tech firms.

16:10

So they have that efficiency. So high tech

16:13

companies have resorted to be more

16:15

of a brand owner. So our customers that

16:18

we have, like Hewlett Packard, Microsoft,

16:22

they're building devices, but they're not

16:24

building it themselves. They use outsource

16:27

partners to do this. So their linkage to

16:30

execution is not to connect their

16:32

boardroom with their own shop

16:34

floor. What they require is

16:37

a business network to collaborate

16:39

intimately with their with their trading

16:41

partners that are doing the

16:44

manufacturing on their behalf. And how easy is it to

16:46

link them in? Yeah. It used to be

16:49

actually a complicated undertaking to

16:51

connect your trading partners. So things

16:54

like EDI, I have been out there for a long

16:56

time, but it is a huge investment to

17:00

actually do that peer to peer plumbing to

17:03

connect a brand owner with their contract

17:06

manufacturer. Often time requires like

17:09

30, 40, 50 different

17:11

data objects that need to be that need

17:13

to be connected from forecasting,

17:16

manufacturing, visibility, work and processes in

17:20

transit orders. Sometimes orders are

17:23

executed in the multi tier way, meaning,

17:27

for example, we have Microsoft using

17:29

our integrated business planning

17:30

environment and they have they

17:35

own sometimes the relationship of the

17:37

second tier supplier. And I think, for

17:40

example, of the camera lens that are

17:42

in in the laptop, they own that

17:44

relation. That's a very

17:45

strategic component.

17:47

So they're buying this and then

17:50

essentially guide

17:52

that buying process. They own that

17:54

relationship and then have that

17:57

dropship to the contract manufacturer.

18:00

So it brings in a new way to do that.

18:03

Real-Time orchestration. And what we're doing

18:06

here, Tom, is is connecting integrated

18:10

business planning with the business network.

18:13

Ariba has innovated their business network

18:16

to actually take on payload for supply

18:20

chain. These objects that I

18:22

mentioned like forecast inventory,

18:24

manufacturing, logistics.

18:26

These processes are now modelled in

18:29

Ariba, so I can now onboard my contract

18:32

manufacturer on the Ariba Network and

18:36

that natively integrates with integrated

18:38

business planning. So now my

18:42

trading partner comes to the planning

18:46

table, if you will, just like an internal

18:48

stakeholder. So that synchronises

18:51

that aspect, which used to be kind of

18:54

arm's length away. I may share a

18:56

spreadsheet over email and then

18:59

wait for response in a in a week.

19:01

That doesn't work anymore. It needs to be real time.

19:04

So that's part of the synchronised planning

19:07

is the business network that we're

19:09

harnessing for this. David, you mentioned

19:13

earlier, when you're talking with, as you mentioned, the user interface then

19:16

that it was the same user interface across.

19:18

How how does that work? And why is that

19:20

important?

19:21

Yeah, great question. I think it is really

19:24

important because user roles are now

19:28

starting to converge, because now I have access

19:31

to planning and execution information.

19:35

I may not need 10 different roles that

19:38

interact with. Different technologies. I can actually bring this

19:41

information together and the same user experiences

19:44

and innovation that we call the planners workspace,

19:47

the planners workspace is essentially one single

19:51

screen. Think of it the morning

19:54

when you open up your Outlook. This is the the window

19:58

to interact with your professional business

20:01

environment. One screen that shows you

20:03

here, the emails of everything that has has

20:06

come up. You can click on one and

20:09

then see the context of this. You can open

20:11

attachments. You have essentially one

20:13

experience. Right. And in this planet's

20:17

workspace aims to do the exact same thing.

20:20

I see my long term plan,

20:22

my midterm plan, my short term plan. And I see

20:25

exceptions. I see things that I need to

20:27

react to that the machine hasn't already taken care

20:31

of. And and now I can say,

20:34

all right, here I have, for example, a sales

20:38

order from a customer that exceeds what I'm currently

20:41

planning on producing. OK, how is the situation?

20:45

I want to I want to get this business.

20:48

I don't have it in inventory. I'm currently not

20:50

scheduling to produce this. Typical example.

20:54

It's a large amount of revenue. By the way, this is a very

20:56

important customer. And they say, hey, we have

20:59

this emergency order. We need more of your

21:03

goods. So how can I react to this

21:07

and get back to that customer in

21:11

like ten minutes? So this requires a

21:14

completely new way of

21:17

organising the user experience. I cannot afford

21:19

to have him go through a labyrinth to

21:23

understand. OK, what is the service

21:26

level that I have for the customer? How much is he

21:29

ordering? Do I have it in inventory? Do I not have it

21:32

in inventory? Can I rebalance the inventory,

21:35

for example, from other customers?

21:37

I need this all in one place to

21:40

immediately make a call.

21:43

OK, I can potentially. Add this to another job in

21:48

a current production line. This is how I'm going to

21:53

ship it to this customer so that the freight aspect

21:57

and transportation resource aspect comes into play.

22:00

Do I have the transportation resources to actually

22:02

deliver this on time? All of this now comes

22:05

together in one environment to make these sort of

22:09

decisions in a very ad hoc way. And we call this

22:12

the the planners workspace very, very exciting.

22:15

We've shown prototypes to two companies

22:19

that were like, hey, this is a game changer for us

22:22

that enables new ways of doing businesses.

22:26

And we have very large companies that we're doing

22:29

conservation on that front, very large consumer

22:33

products companies. If I would tell you, you would immediately know,

22:36

because I think they're at the forefront of innovating

22:40

new business models. I mentioned direct to

22:43

consumer models. They're on the forefront

22:46

of more sustainable ways to deliver the goods of

22:50

providing more efficiencies, but also improve actually

22:54

the ultimate customer experience with more

22:57

kind of the... I love the other podcast

23:00

that you did with Coca-Cola. "The speed to need" to

23:03

ride the speed to actually service customers when

23:08

it is needed. And that may be in the here

23:11

and now today. So it is that

23:16

what we're actually catering to with our technology?

23:19

Super, super. We of gone over the 20

23:22

minute mark, David. So we're in kind of the wind

23:26

down period of the podcast now.

23:28

Is there anything I've not asked you that do you think

23:30

I should have asked? Are there any points we've not brought up that you

23:33

think it's important for people to be aware of?

23:36

Yeah, I think just the clarification I talked

23:39

about some because this question will come up for

23:42

especially for customers that for, for example, have

23:44

been SAP customers for a long time.

23:46

They may be familiar with integrated business

23:49

planning. They may be familiar with production

23:51

planning and detailed scheduling. Will this become one?

23:54

Will this be integrated somehow?

23:57

Will this be on premise? Will this be cloud?

24:00

I just want to clarify. Integrated business

24:02

planning is is will be our go forward

24:06

solution for doing supply chain planning at SAP.

24:10

That is where the

24:12

the user experience will surface all the

24:15

information necessary to make decisions because

24:18

ultimately supply chain planning is a

24:22

framework of decision making.

24:25

I need to make decisions as things are changing.

24:28

I need to decide what to do next.

24:31

And so integrated business planning will bring the

24:34

Real-Time visibility will bring essentially the

24:38

finance aspect. Does it make sense

24:41

to stick to the example? Does it make sense for me

24:45

to service this customer orders that just came in

24:48

unexpected? Does that make sense to me

24:51

financially? Is it still profitable?

24:54

Right. If I if I have to put it into an aeroplane

24:57

to send it over and with overnight freight that

25:00

burns away, all the profit perhaps doesn't make sense.

25:04

Perhaps it's OK for the customer to wait another

25:06

day. And these types of decisions

25:09

have to be made. Our go forward solution for

25:11

that is Integrated Business Planning in the cloud.

25:14

The synchronised planning aspect means that we're

25:18

integrating into auxiliary assets from an

25:22

SAP perspective to seamlessly support

25:26

that decision process. So there will still be

25:30

things like transportation management, production

25:33

planning. These are all supporting aspects for

25:37

a cohesive supply chain planning.

25:39

But the good news is I don't have to guess where

25:43

to go to to make a decision.

25:45

That will it be happening in IBP

25:48

how we call it an abbreviated.

25:51

Super Dave if people want to know more about

25:55

yourself. David Valejo, or about synchronised

25:57

planning or about IBP or any of the other

25:59

things we talked about on the podcast today,

26:03

where would you have me direct them?

26:05

Oh, very easy. SAP is always a big

26:08

fan of three letter acronyms, so SAP dot

26:11

com slash IBP. Very simple to

26:14

remember where you can find more

26:15

information about IBP.

26:18

We have an extremely active community

26:21

that is not just technology, but we

26:24

have a partner network of system

26:28

integrators and management consulting

26:31

firms that all are informed about

26:35

IBP best practises. It's a rich community

26:38

that we have. You can look myself

26:40

up on LinkedIn, on Twitter, and

26:44

I'm very active. That community as

26:46

well. Very happy for for

26:49

somebody who wants to learn more.

26:51

Superb. Superb. David, that's been

26:52

great. Thanks a million for coming on the show today.

26:55

Thank you very much, Tom, for having me. And you have a great

26:58

rest of your day. Thank you, everyone.

27:02

OK, we've come to the end of the show.

27:04

Thanks, everyone, for listening. If you'd like to know more

27:07

about digital supply chains, head on over to

27:10

S.A.P.. Dot com slash digital supply chain.

27:12

Or simply drop me an email to Tom Dot Raftery at SAP

27:16

dot com if you'd like to show.

27:20

Please don't forget to subscribe to it. And your podcast

27:22

application of choice to get new episodes as soon as

27:25

they're published. Also, please don't forget

27:28

to rate and review the podcast. It really does help new

27:31

people to find the show. Thanks.

27:34

Catch you all next time.

From The Podcast

Sustainable Supply Chain

Welcome to the Sustainable Supply Chain podcast, hosted by Tom Raftery, a seasoned expert at the intersection of technology and sustainability. This podcast is an evolution of the Digital Supply Chain podcast, now with a laser-focused mission: exploring and promoting tech-led sustainability solutions in supply chains across the globe.Every Monday at 7 am CET, join us for insightful and organic conversations that blend professionalism with an informal, enjoyable tone. We don't script our episodes; instead, we delve into spontaneous, meaningful dialogues about significant topics, always with a touch of fun.Our guests are a diverse mix of influencers in the field - from founders and CxOs of pioneering solution providers to thought leaders and supply chain executives who have successfully implemented sustainability initiatives. Their stories, insights, and experiences are shaping the future of sustainable supply chains.While the Sustainable Supply Chain podcast addresses critical and complex issues, we aim to keep the discussions accessible, engaging, and, most importantly, actionable. It's a podcast that caters to a global audience, reflecting the universal importance of sustainability in today’s interconnected world.We are always eager to hear from our listeners. Your feedback and suggestions are invaluable to us, helping shape the podcast into a platform that truly resonates with its audience. Feel free to reach out via email or connect with us on social media to share your thoughts, ideas, or just to say hello.Subscribe to the Sustainable Supply Chain podcast and be a part of this crucial conversation. Together, let's explore how technology and innovation can lead the charge in creating more sustainable, responsible, and efficient supply chains for a better tomorrow.Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

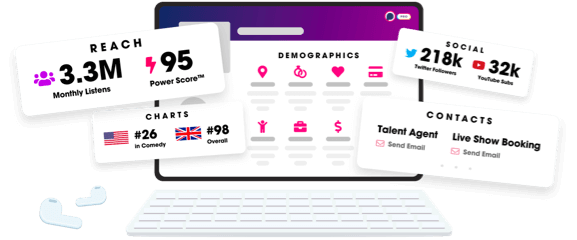

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us