Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:03

Many people forget

0:03

that the supply chain itself can

0:06

only correct and, and optimize

0:06

about 20% of the efficiency

0:11

rate in the entire supply chain. 80% is being decided when you

0:13

design a product and when you

0:16

create the product, right? And when you start making

0:18

sourcing decisions.

0:21

So this is where you actually define how

0:21

your supply chain looks at the end, right?

0:24

If you, if I define and design a product

0:24

where all my components come from across

0:30

the world of course I, my supply chain,

0:30

my carbon footprint is really big.

0:35

Good morning, good

0:35

afternoon, or good evening,

0:38

wherever you are in the world. This is the Sustainable Supply Chain

0:39

Podcast, the number one podcast

0:43

focusing on sustainability and supply

0:43

chains, and I'm your host, Tom Raftery.

0:49

Hi everyone. And welcome to episode 10 of the

0:49

sustainable supply chain podcast.

0:53

My name is Tom Raftery, and I'm

0:53

excited to be here with you today.

0:56

Sharing the latest insights and

0:56

trends in supply chain sustainability.

1:01

Today, we're talking to Hans Thalbauer

1:01

from UI Path and in upcoming episodes,

1:06

I'll be talking to Marcus Hoed from

1:06

Dutch X, talking about logistics.

1:10

Brian Merkling from Thinaer talking about

1:10

IOT, and Madhu from Schneider Electric

1:15

talking about Schneider Electric's own

1:15

improvements in their supply chain.

1:20

So fascinating episodes coming up. If you want to be sure to catch

1:22

them, follow this podcast in

1:25

your podcast, app of choice. Before we kick off today's show.

1:28

I want to take a moment to express

1:28

my gratitude to all of this

1:31

podcast's amazing supporters.

1:34

Your support has been instrumental

1:34

in keeping this podcast going.

1:37

And I'm really grateful for

1:37

each and every one of you.

1:41

If you're not already a supporter. I'd like to encourage you to consider

1:43

joining our community of like-minded

1:46

individuals who are passionate about

1:46

sustainability and supply chains.

1:50

Supporting the podcast is easy and

1:50

affordable with options starting as low

1:53

as just three euros or dollars a month. That's less than the cost of a

1:56

cup of coffee and your support

1:59

will make a huge difference in

1:59

keeping the show going strong.

2:02

To become a supporter, simply click

2:02

on the support link in the show notes

2:06

of this, or any episode or visit.

2:08

Tiny url.com/s S C pod.

2:14

Now. Without further ado.

2:16

I'd like to introduce my

2:16

special guest today Hans.

2:20

Hans, welcome to the podcast.

2:22

Would you like to introduce yourself?

2:24

Thank you, Tom. Thank you for having me. And yeah, of course.

2:26

My name is Hans Thalbauer. I'm looking after the global

2:27

supply chain practice, at UiPath.

2:32

My background is supply chain. I was working in this industry

2:33

for, I would want to say 25 years

2:37

now, in different companies at

2:37

SAP, Google, and now at UiPath.

2:42

Okay. And for people who might be unaware Hans,

2:42

can you tell us a little bit about UiPath?

2:47

Who, who are UiPath? What is it you do there?

2:51

Yeah, UiPath

2:51

is all about AI powered

2:54

automation of business processes.

2:56

there's a platform, which we use in order

2:56

to apply it for business, processes.

3:01

It has a discovery layer, it has an

3:01

automation layer and an operation layer.

3:05

The discovery layer is all about

3:05

process mining the task mining

3:10

and communications mining. So understanding the business processes,

3:11

the automation layers, all about how to

3:15

automate the business processes with AI

3:15

technology, but also with software robots.

3:20

And then you have an operation layer which

3:20

makes it scalable for the enterprise.

3:25

Okay, and this Hans is

3:25

the Sustainable Supply Chain Podcast.

3:30

So what are you doing here?

3:35

Yeah. Yeah. So I'm thinking, you know, about

3:36

the business processes in supply

3:39

chain all my life actually. And so, I'm of course very, very

3:41

interested in the sustainability topic.

3:45

Sustainable supply chain is one

3:45

of the key drivers, I want to say.

3:48

And most important aspects we need,

3:48

we need to drive and think about

3:53

in the supply chain context, why? Because I believe there are three areas

3:55

which we can really, really impact.

3:59

There's of course, the carbon footprint

3:59

and how we can reduce carbon footprint.

4:03

And if you think about the supply

4:03

chain definition and the sustainability

4:07

definition of carbon, we have

4:07

the scope one, two, and three.

4:10

And my focus is really

4:10

on, on the scope three.

4:12

So on the indirect emissions,

4:12

everything related to supply

4:16

chain, upstream and downstream. So that's the first big area.

4:20

The second area is really circular economy. And I think there's not enough discussion

4:22

around the circular economy and how we can

4:26

really reduce the usage of material and

4:26

really get into a more circular economy.

4:32

And the third aspect is all about social

4:32

responsibility and I think a topic

4:36

super important and really involving

4:36

all the people around the world.

4:40

Supply chain is always global, so

4:40

we need to think globally and also

4:44

take social responsibility globally. So those are the three topics I'm

4:46

working on and thinking about and how

4:50

to apply also automation into this and

4:50

make it easier for companies to work on

4:56

these three topics and reduce actually

4:56

carbon footprint, have more awareness

5:00

on the social responsibility, and

5:00

increase the circular economy aspects.

5:05

Okay, so we'll, we'll take

5:05

the first one, the carbon footprint.

5:09

What are you seeing that's

5:09

happening in that space?

5:12

It's an interesting space, obviously,

5:12

because to my mind it is the

5:16

most important one, although the,

5:16

the, the circularity is linked

5:20

to carbon footprint as well. It is to my mind the most

5:22

important given the, the climate

5:25

emergency that's out there. But, and there's a lot of

5:27

regulation coming down in companies.

5:29

There's a lot of pressures in

5:29

companies from investors from,

5:33

banks from insurance companies, from

5:33

employees from all sides really.

5:39

How are companies responding?

5:43

Yeah, that's very,

5:43

very, very interesting question.

5:45

Right. So let's start first in my observation

5:45

working with companies around the

5:49

world and how important the topic

5:49

of sustainability and especially

5:53

carbon footprint is for companies. In Europe, definitely

5:55

this is high priority.

5:58

Right. So no doubt about this at all.

6:01

In North America, unfortunately, it's

6:01

still not the number one priority, right?

6:05

So you would still have, yes, we

6:05

want to be more sustainable and

6:08

yes we have our targets by 2025,

6:08

by 2030, we want to achieve.

6:13

Less carbon footprint and reduce

6:13

the, the carbon footprint.

6:17

Some companies, especially in the IT areas

6:17

are really having a strong focus there.

6:22

They want to run their data center

6:22

only with renewable energy and so on.

6:26

But in general, i t's still

6:26

not the number one priority.

6:30

And if you look at Asia, it's

6:30

somehow in between Europe and,

6:33

and North America, I want to say. And so we still around the world

6:35

are not yet at a level where I would

6:39

see the strong urgency, you know,

6:39

and focus on Yes, now we really

6:44

need to make a big difference. Despite all the weather and

6:46

climate issues, which are

6:49

very obvious to everyone, it's

6:49

still not at, at this level.

6:52

Right? So that's my first observation.

6:55

When it comes down to, to the carbon

6:55

footprint and especially the, the

6:59

reductions I think actually are many

6:59

companies who made a huge progress, right?

7:04

So really a lot of progress

7:04

in, in how they can actually

7:07

decrease carbon footprint. When I think about supply chain.

7:10

There's still a huge opportunity,

7:10

and I think the last couple

7:14

of years there was a a change.

7:18

And the change in really

7:18

restructuring and rethinking supply

7:21

chain becoming more regional. Right? So one of the key topics I think we

7:23

need to address is supply chain is

7:28

very global and it'll remain global. However, you can regionalize much more.

7:33

Source actually differently. And with that really have a different

7:34

network, a supply chain network.

7:38

One of the biggest issues

7:38

is the transportation area.

7:41

And in transportation, think about

7:41

all the trucks which are empty

7:46

on the street how many ships we

7:46

need and going around the world.

7:50

They're getting bigger and bigger

7:50

and through to geopolitical

7:53

issues, take longer routes.

7:55

And so we have all these issues.

7:57

And then we have also the aspects

7:57

on how we measure carbon footprint.

8:03

I think that's the third aspect, right? So first one, what is the awareness?

8:07

Second one is really what

8:07

companies are progressing.

8:10

And I think there is progress, however,

8:10

supply chains need to restructure.

8:13

And the third is really how

8:13

we measure carbon footprint.

8:16

And I think it's still too much

8:16

average data, which we are using

8:21

in order to measure actually the

8:21

real carbon footprint especially

8:25

when it comes to scope three data.

8:27

And how do we fix that?

8:31

Yeah, that's a big, big question, right? So on the, on the first one, I

8:33

think there are many, many programs

8:36

in place and you just need to look

8:36

at the World Economic Forum, and I

8:40

think they take it very seriously. And we think the different regulations

8:41

and in the different regions of the

8:47

world, I think there is progress, right?

8:49

It's slower than I think it should

8:49

be, but there is progress, right?

8:52

And I think the climate discussion is.

8:56

Not the question anymore that

8:56

there are climate changes.

8:58

I think this is resolved. At least I would.

9:01

I I would

9:01

hope so. yeah,

9:03

yeah, but so I, I

9:03

want to say on the first one, I'm an

9:07

optimist, so I think there is progress. The second aspect on, on the

9:09

restructuring, I think companies

9:14

started to understand and, and really

9:14

think about the value of having a

9:18

supply chain which is more efficient. And it starts with the

9:20

design of the product, right?

9:22

So many people forget that the supply

9:22

chain itself can only correct and, and

9:27

optimize about 20% of the efficiency

9:27

rate in the entire supply chain.

9:31

80% is being decided when you

9:31

design a product and when you

9:35

create the product, right? And when you start making

9:36

sourcing decisions.

9:40

So this is where you actually define how

9:40

your supply chain looks at the end, right?

9:43

If you, if I define and design a product

9:43

where all my components come from across

9:49

the world of course I, my supply chain,

9:49

my carbon footprint is really big.

9:53

And so in these decisions we have

9:53

all these aspects I mentioned at

9:57

the beginning, coming together. We have the circularity, which is coming

9:59

together right at the design phase.

10:03

If I design for circular economy,

10:03

I have a different end result.

10:07

The second one, the social responsibility.

10:10

How, which countries do I work? What kind of labor laws and regulations

10:11

are in place in order to ensure that

10:16

there is no child labor, there's

10:16

no slave labor, and so on, right?

10:20

So I can make the decision, right? at the design phase and

10:22

the carbon footprint, the

10:25

impact on, on carbon, right? So it can also make at the design phase.

10:28

So my biggest focus actually is

10:28

to really think how can we create

10:35

actually the awareness on the design

10:35

of products to make that differently.

10:39

And so this is, I think the,

10:39

the biggest area where we can

10:43

make the biggest difference. Then I make the decision where to source

10:45

and make it more local, make it actually

10:50

from a transportation perspective better.

10:52

And I can automate and optimize the whole

10:52

supply chain in a much, much easier way.

10:57

So these are some ideas, right? So where I think the, the

10:59

biggest aspect is really.

11:03

Thinking about the product design and

11:03

which components, which ingredients

11:07

I take for the, for the product. And from there I can really

11:09

make a big, big difference.

11:13

Okay. And what about, you mentioned the

11:13

measurement of carbon footprints and

11:17

how a lot of it is done using averages

11:17

or estimates as opposed to actual data.

11:23

How do we fix that?

11:25

Yeah, that's a big question as well. Right.

11:27

So I think there is there needs

11:27

to be some more regulation.

11:31

I absolutely believe there needs

11:31

to be more regulations, more

11:34

standards which need to be defined

11:34

by the countries and states.

11:38

And I mean, at the moment what you

11:38

see, the greenhouse gas protocol

11:42

which is good, which I like, and, but

11:42

it's kind of, open for every company

11:46

to, to submit their data, right?

11:49

And then averages are being calculated.

11:52

And there are some protocols and

11:52

standards, and I like every, everything

11:55

what they, what they actually do, right? So where they say, okay, if you have

11:57

the correct data, use the correct data.

12:01

If you don't, then go and, and use

12:01

averages, and they have methods how

12:07

to do the calculations and so on. So great work, I think, and,

12:09

and really a good guidance for

12:12

companies how to access this data. But wouldn't it be possible to

12:14

really go and, and calculate the

12:18

data for every product you produce?

12:20

I think it is. We can calculate the cost, right?

12:23

For every product. Why can't we calculate the carbon

12:24

footprint and capture it actually

12:28

while it's being produced and

12:28

while it's being transported, and

12:31

use it exactly as it is, right? So there you could see if, how

12:33

many returns you had on the

12:36

product how many times you, you did

12:36

actually ship it across the world.

12:40

What kind of components were coming from where? I think it is possible from

12:43

a technology perspective.

12:46

I don't see where, where we would've

12:46

an issue, but it's not being done.

12:51

And maybe there's some issues also

12:51

with, with IT and investment in IT

12:56

and sharing information, sharing data.

12:58

I mean, since ever when it's about

12:58

collaboration, there's a hesitance

13:02

between companies to share all

13:02

the information they have, right?

13:05

So I think this is a, a, a big topic.

13:08

This is actually an area where I think

13:08

the whole discussion around artificial

13:12

intelligence can make a huge difference. Why?

13:14

Because I think these topic topics

13:14

around communications mining, intelligent

13:19

document processing, where you can

13:19

submit unstructured information

13:24

and still the machines can read all

13:24

this unstructured information, and

13:29

transform it into structured data. Right?

13:31

So this is, I think, one method where

13:31

you just need to think, well, I can

13:36

easily submit my data via email.

13:38

That's fine, right? I don't need an EDI API and what

13:40

have you type of infrastructure.

13:45

I can just use email and type actually,

13:45

or put an attachment on there.

13:51

Then I use artificial intelligence,

13:51

which can read the emails, which can

13:55

read the attachments, categorize the

13:55

information, pull the information

14:00

out, and bring it to the right reports

14:00

or push it forward to, to planning

14:04

and optimization algorithms, right? So the technology is there to do

14:05

that and make it much more simple and

14:10

easy for companies to collaborate.

14:13

And so. Again, I'm optimistic that we get better,

14:14

but at the moment it's still very average.

14:18

And we need to work and leverage now

14:18

really this discussion around artificial

14:23

intelligence in supply chain and

14:23

how we can make a difference there.

14:27

Sure, and that leads

14:27

back to your earlier point then

14:30

about design and sourcing because as

14:30

you get that information from your

14:35

suppliers, it feeds back into who you're

14:35

actually using to be your suppliers.

14:40

When you start to see the carbon

14:40

footprint implications of using

14:43

supplier A over supplier B, for example.

14:46

Yeah, absolutely. Right? So think about in

14:47

consumer products, right?

14:49

So you define a new product, you want

14:49

to understand where the ingredients

14:53

are coming from and so on, right? And especially when it comes

14:55

to the ingredients the sourcing

14:58

of those it can come from or,

14:58

or variety of countries, right?

15:03

And you need to bring them together. And now you need to also not only think

15:04

about what is the carbon footprint of the

15:09

sourcing, but also what kind of energy is

15:09

needed in order to produce this component?

15:15

What kind of impact does it have if I get

15:15

these ingredients through deforestation

15:21

or all these kind of aspects? Right?

15:23

So think about it in a

15:23

bigger context, right?

15:26

So not just, yes I now have a carbon

15:26

footprint because I get product

15:31

shipped ingredient shipped from Brazil. Think about also what does, is

15:33

the impact in order to harvest

15:37

this, this ingredient, right? What is the impact there?

15:39

Is there enough water to to do that?

15:41

Can people actually do that? Is the social responsibility

15:43

there and on, right?

15:45

So this is, these are all the aspects

15:45

which we need to consider in, in this

15:49

context and think about in a holistic way.

15:53

And this holistic way means

15:53

I have thousands of data.

15:58

And I need a machine in order

15:58

to help me with that, right?

16:01

So therefore, again, my big hope

16:01

is that artificial intelligence can

16:06

make a big difference here, which

16:06

can go through these data lakes and

16:10

understand actually this combination

16:10

of data in a much better way.

16:14

Of course, you know, algorithms are

16:14

necessary in order to have the right

16:17

learning of the data because you can

16:17

teach the algorithms the wrong thing.

16:21

And so we need to really have

16:21

patterns in place which really allow

16:25

the algorithm to learn the right

16:25

things and then really giving the

16:28

right advice to the people, right?

16:30

And, and so from a technology

16:30

perspective, it's there, but I

16:35

think we need to combine these

16:35

thoughts in a more holistic thinking.

16:39

Yeah. Yeah. And a lot of this can be quite

16:39

counterintuitive as well.

16:44

I mean, you, you talked rightly about

16:44

regionalization, but in some instances,

16:50

just depending on the, the manufacturer,

16:50

sometimes bringing something from

16:55

China can be lower carbon footprint

16:55

than manufacturing something locally.

16:59

And you know, an example I heard of

16:59

that recently, not in the manufacturing

17:04

space was, but in the food space,

17:04

was people talk about, you know.

17:08

Bringing in avocados from South America? Well, yeah, the, the amount of the

17:10

carbon footprint of transportation in

17:15

avocados is high, but the rest of the

17:15

production of the avocados is quite

17:21

low in terms of its carbon footprint. If you're comparing that to say,

17:23

locally sourced beef, well, beef has a

17:28

very high carbon footprint, enormous.

17:30

So in fact, those avocados.

17:33

Brought in from South America

17:33

would have a much lower carbon

17:36

footprint than locally sourced beef. So, you know, a lot of these things

17:38

are very counterintuitive and it's

17:41

only by parsing all of that data to

17:41

your point, can you see which is, you

17:46

know, better or worse than the other. And it also depends on your

17:48

suppliers actually supplying that

17:53

data and it being verifiable data.

17:57

And in that scenario, you gotta be

17:57

very aware, I think that if you are

18:03

sourcing from suppliers who are not

18:03

supplying that data, you're putting

18:07

your organization at risk, right?

18:10

Yeah, absolutely. And, you know, perfect example you

18:11

just brought up because I, I think you

18:48

cannot, well, my belief is in, in, in the

18:48

freedom of trade and, and so on, right.

18:55

So it's not really restricting

18:55

everything not getting rid of all

19:00

the advantages we have made over

19:00

the last a hundred years, right?

19:04

So I think we should not go and think,

19:04

well, we need to go back a hundred

19:10

years and then everything is good. I don't believe that at all.

19:13

Right? So I think we need to

19:13

look into the future. How can we actually reduce and, and

19:15

use technology in order to reduce the

19:21

carbon footprint and so on, right? So I think this is the thought,

19:22

not being against something,

19:27

but being for something. And so that means I need to allow

19:28

actually the possibilities to, to,

19:33

have the products also produced

19:33

locally and globally, right.

19:37

I think one of the big issues is

19:37

of course, you know, we, we in,

19:41

in the society overall, right? So we, we need to make

19:42

it affordable, right?

19:45

So, the mass production and all

19:45

the outsourcing in the direction

19:48

of China, at the beginning it was

19:48

all because of cheap labor, right?

19:53

So it's not anymore, but it used

19:53

to be because of cheap labor.

19:56

So that's why all the advantages

19:56

were possible so that more the mass

20:02

actually of people, so more people

20:02

could get affordable products.

20:07

Yeah. Which they couldn't get before.

20:09

And so now telling everyone, well

20:09

only the rich can get actually this

20:14

still product, this, this product

20:14

still, and, and, and the poor don't,

20:18

would have a real social impact. Right.

20:21

And, and I think actually this

20:21

is not the way we should go.

20:24

Right. So we actually need to, have these aspects

20:24

in mind, what does it do to the society

20:29

and how can we actually use technology

20:29

in order to overcome some of these

20:34

issues and make it make it better, right?

20:37

So I think, yeah, like I said before,

20:37

it's, it's really about bringing

20:40

together all kinds of different thoughts

20:40

in, in this, in, in this environment.

20:45

Yeah. Yeah.

20:46

but it's true, these

20:46

examples, with beef and avocados.

20:51

Right. So it's, it's a very good one because

20:51

it immediately shows you where, where

20:56

actually the, the issues can be.

20:59

Right. So when you just look at the

20:59

data and you say, this is good

21:01

or bad, well, is it right?

21:03

Yeah, exactly, exactly. The other point, what, well

21:05

the second point you mentioned

21:07

was around circular economy. So talk to me a little bit about that.

21:11

It's, it's, it's an interesting

21:11

one because it feeds very much to

21:15

your point about, you know, design. You need to design things

21:16

for them to be circular.

21:20

And, and that feeds into

21:20

sourcing decisions as well.

21:23

But also it feeds into carbon

21:23

footprint decisions at, at end

21:27

of life or at, you know, when at

21:27

end of useful life, et cetera.

21:32

So talk to me a little bit about circular

21:32

economy and how you see that going.

21:37

So interesting enough,

21:37

I was reading quite a number of reports

21:41

about circular economy and where we are

21:41

with the circularity at the moment, right?

21:46

And interestingly enough, right?

21:48

So in, in, in 2020 there were was

21:48

about 9% circular economy, right?

21:54

So the circularity was 9%.

21:56

And it reduced the last a couple of years.

21:59

Now it's about 7%, 7.2%, and that means

21:59

we are still, yeah, creating products

22:06

and using products from new well from,

22:06

from new material and, and, and so

22:11

instead of reusing material, right?

22:13

So this is kind of the the biggest issue.

22:16

And why is that? It has to do also with the whole

22:17

recycling technology and the sorting

22:21

technology and, how to actually get

22:21

to the products or the raw materials

22:26

again, which you need in order to create

22:26

high quality products again, right?

22:29

So that's what it comes down to. I think when you look at the

22:31

plastic discussion, right?

22:33

And how you leverage plastic. It all comes down to can you recycle it.

22:38

There are technologies in place

22:38

where you can get real good source

22:43

material again, in order to reproduce.

22:45

But in general this is

22:45

not yet mass production.

22:49

This is very, very low percentage

22:49

actually, where you get actually

22:54

the, the plastic recycled. And so here we have a, a, a big issue.

22:58

This is only the plastic discussion we

22:58

can go on with many more discussions.

23:01

There are also some good aspects, right?

23:03

So where I think. In the context of electric

23:05

vehicles and the batteries, right?

23:09

There is this battery passport

23:09

kind of, concept, which I like a

23:13

lot, which is really doing what,

23:13

what we discussed before, right?

23:16

So how to create actually circular

23:16

economy and thinking that right

23:20

from a design perspective. And so I think actually there, it has been

23:21

proven with this case that it is possible

23:28

to get to a much better outcome than then

23:28

if you don't do that, right, if you just

23:32

produce the batteries and then you throw

23:32

them away, well, what a waste, right?

23:36

And it's not really good

23:36

for the environment.

23:38

So you need to have the,

23:38

the circularity in mind.

23:42

And if you do that more and more for

23:42

different product categories, right?

23:45

So think about aluminum and

23:45

steel and plastic and all

23:49

these kind of things, right? Then we getting in a, in a much

23:50

better en en environment and I

23:54

think there's not enough focus.

23:57

And there needs to be much more focus on,

23:57

on how to get to a more circular economy.

24:01

And I think the productivity aspect,

24:01

the cost need to be considered there.

24:06

I think think about all the retail

24:06

and e-commerce topics, right?

24:11

The, the return of products how many

24:11

people ship their products back, right.

24:17

And return it. And it's, it's considered to

24:18

be free, free of charge, right?

24:22

So I think that's another issue, right?

24:25

Because well, retailer

24:25

in, in the competition.

24:28

Well, let's offer this free of charge.

24:30

Because it's free, everyone is doing it.

24:33

Right. So I think actually there are aspects

24:33

where if we would really cover the,

24:38

or calculate the real cost on this,

24:38

and also the carbon footprint on

24:42

this, maybe there would be some

24:42

rethinking around this, right?

24:47

So there are certain areas where we

24:47

could really make a big difference in

24:50

the whole aspect of, of circular economy.

24:53

Yeah, yeah, yeah, yeah. I, I came across a, an

24:54

interesting example recently.

24:58

I remember when I was a kid, I

24:58

dunno if it's the same for yourself.

25:01

I'm a, a couple years older than you, but

25:01

I remember when I was a kid, you used to

25:05

get money back on bottles, glass bottles.

25:09

So when I was a kid, I used to go

25:09

around collecting glass bottles and

25:12

bringing them to shops and making

25:12

a bit of money for myself that way.

25:17

And that died out for a while.

25:19

And now all bottles are

25:19

plastic, unfortunately,

25:22

well, the vast majority are. But just last week or early this week.

25:27

In Ireland, they rolled out a new

25:27

deposit return scheme for tin cans

25:35

and aluminum cans and plastic bottles.

25:38

So now there's about 4,000 machines

25:38

in shops throughout the country.

25:45

And if you bring back a a can, or

25:45

a bottle, and you put it into these

25:51

machines, it spits out a voucher for you.

25:55

And the voucher is for, I think it's 15

25:55

cent or 25 cent, depending on the size or

26:00

the composition of the can or the bottle.

26:02

And you can then redeem that in that

26:02

shop against other purchases, or you

26:07

couldn't get cash for it directly.

26:10

So, I remember Ireland was the

26:10

first country in the world to

26:13

roll out a tax on plastic bags,

26:13

single use plastic bags in shops.

26:19

It started off, I think it

26:19

started off just being 5 cent,

26:22

five euro cent per plastic bag. But you saw a reduction in use of

26:24

plastic bags of around 90 to 95% straight

26:31

after the introduction of that levy. And now I gotta think with this,

26:33

because this, cash back means

26:38

there's an increase in the upfront

26:38

cost of these cans and bottles.

26:42

So you gotta think people are gonna

26:42

have a, a mindset change around this.

26:49

And you, you see in countries where

26:49

these kind of schemes are rolled out,

26:52

a big reduction in the, in the use

26:52

of plastic and, and more recycling.

26:57

This is, this is one

26:57

potential solution I see.

27:00

Is, is do, do you see that happening

27:00

in other countries much as well.

27:05

Oh, absolutely. Right. So I think all over Europe, right?

27:08

So you see that happening. There are also some initiatives

27:09

actually in the US right?

27:12

So I don't want to say

27:12

there's not no initiatives.

27:14

There's some initiatives here also

27:14

by the big bottling companies.

27:17

Right? So think about Coca-Cola and PepsiCo

27:17

and, and all of these, right?

27:21

So they all of them are really

27:21

want to make a difference and have

27:25

introduced different initiatives in

27:25

order to get the cans recycled, to

27:30

get the bottles recycled and so on.

27:32

Right? So, many companies are really

27:32

going in this direction and, and

27:35

thinking about this and, and not

27:35

just thinking, but introducing also

27:39

real methods in, in order to do that.

27:41

In, in Europe especially, right? I mean, you brought up Ireland.

27:44

I come, well, originally from Austria

27:44

and also there we have the same

27:49

kind of concepts It's right now

27:49

really on the, on the glass, right?

27:53

So that you return glass

27:53

bottles in, in the retail shops.

27:56

Now I think beginning next year, it's

27:56

also the plastic bottles are similar to

28:01

the example you described on in Ireland.

28:04

I think there are also, you know,

28:04

with use of technology instead of

28:08

having bottled water, you get more

28:08

and more of these systems where in

28:12

the water supply you can include it.

28:15

So you have your, your water directly

28:15

coming actually in instead of bottles.

28:19

You don't need to buy them anymore. You, you actually get it directly from,

28:21

from your, from your water supply.

28:24

And so it's very different

28:24

systems which are being placed.

28:28

And again, I am big believer in

28:28

technology makes a difference

28:32

and new ideas and innovation is,

28:32

is really helping here a lot.

28:36

So, but circular economy, I think

28:36

in, in general when it comes to the

28:40

scarcity of material we know that

28:40

many materials are really scarce.

28:44

Many of them are coming from China. There's a dependency there.

28:48

We use them in high tech products a lot.

28:50

We use them in aerospace

28:50

and defense a lot.

28:52

And I think also here there needs

28:52

to be rethinking in terms of which

28:57

materials to use and isn't in there

28:57

another material which we could use.

29:01

So, again, I think one of the sources

29:01

when I think about all the problems is

29:06

really in the design phase of a product

29:06

where all the difference can be made.

29:10

And how the carbon footprint ends

29:10

up, how the circularity is and also

29:16

the around the social responsibility. It all starts directly at the sourcing

29:18

decisions and the design decisions,

29:22

which are made very early in the process.

29:25

Yeah. And I'm glad you mentioned

29:25

the social responsibility.

29:27

It was your, your third

29:27

point when you started off.

29:30

That's always gonna be trickier than, I

29:30

mean, carbon footprinting, is is hard.

29:36

Measuring emissions is hard, but the

29:36

social responsibility one is harder even

29:42

again, I gotta think not just in terms of

29:42

measurements, but also in terms of what to

29:49

measure because it's, I think it's such a

29:49

new and immature area that the standards

29:56

to report to are still not quite there.

30:00

But is there, is this something

30:00

that technology can help us with?

30:04

I think so. Right. So how is it being done

30:05

at the moment, right?

30:08

At the moment you send somebody

30:08

and audit your supplier.

30:12

Right. It's really once a year you

30:13

audit your supplier and you

30:17

only see what you see, right? So if the supplier leads you to a plant

30:19

where everything is perfect and fine.

30:24

And let's say the mine is

30:24

perfect and fine, then well,

30:27

you know, the audit is good. And if they have another plant behind

30:29

that or another mine where children

30:34

are working or whatever aspects are

30:34

going on, you might not be aware of it.

30:39

Right? And you only know once you see a

30:39

report in the news and your supplier is

30:44

actually in the news and maybe there's

30:44

even an impact on your finished product

30:49

because now you get a bad reputation

30:49

in working with this type of supplier.

30:52

Right? So I think there are many examples

30:53

in, in, in the world, which, where,

30:57

where we know that happened already. I think there are technology

30:59

can really help and why and how.

31:02

It's, it's of course the audits, right? But at the same time, what you can do

31:04

is you can actually read local news.

31:10

So think about all the risk

31:10

management activities where you

31:15

can actually read local news. And in local news, you might find actually

31:16

some hints that in this plant there was

31:21

some issues, there were some issues.

31:24

There there was maybe a fire,

31:24

there was something, right?

31:27

So the more you get actually

31:27

information and warning signals

31:31

of, oh, that doesn't look right.

31:34

Right. So the more you actually

31:34

increase the risk level, right?

31:37

And then you have a very different

31:37

discussion with the audit.

31:40

So, there are ways where you take

31:40

information, which is there, and

31:45

many times it's locally news. You use artificial intelligence

31:47

again in order to read through

31:50

that and determine the risk level.

31:53

And then your, the combination of the

31:53

risk level and the audit will determine

31:58

then do I have a problem or not, right?

32:01

So it's one way of doing it a little

32:01

bit different and using more information

32:08

in order to make the decisions.

32:10

Yeah. Yeah, because that is as, as you

32:10

said already, that is the, the

32:14

one thing that AI is great at is

32:14

sifting through enormous amounts of

32:19

data that no one person could do.

32:21

But if you get access to enough

32:21

information and data sources and you

32:25

feed that into an ai, properly trained,

32:25

it should be able to spit out meaningful

32:31

information for you to make decisions.

32:34

Absolutely. The only problem is, how to know

32:35

who is your supplier, right?

32:39

So you might think, whatever, this

32:39

is a little bit stupid what I'm

32:42

saying, but it is true, right? So typically a company an OEM

32:43

knows the tier one supplier,

32:50

but not the tier two, right?

32:52

So they, they don't know who is

32:52

actually the supplier of the supplier.

32:57

And then think about

32:57

the raw material, right?

33:00

So how much, what was the percentage

33:00

of this raw material from this

33:04

one mine, which came then in this

33:04

product and then in this component,

33:09

and then in this product and on. So through the value chain,

33:11

who is your supplier?

33:14

Right? So this is, I think one of

33:15

the unresolved questions.

33:18

It's, it's really not resolved, right?

33:21

So you can go to any automotive

33:21

OEM and ask them who are

33:24

your tier three suppliers? Answer is, I don't know.

33:28

Right? And so here we need to make actually

33:28

a more effort how can we can improve

33:33

the transparency and how we actually

33:33

go through the supply chain and

33:38

really allow a more end-to-end view

33:38

on, on the supply chain itself.

33:42

Yeah. Yeah, yeah, yeah, yeah. Cool, cool. We are coming towards the end of

33:45

the podcast now, Hans, is there

33:48

any question I did not ask that you

33:48

wish I did or any aspect of this we

33:53

haven't touched on that you think it's

33:53

important for people to think about?

33:57

No, I enjoyed the conversation. I think it's an important conversation.

34:01

I think the all three aspects we were

34:01

covering are really dear to my heart.

34:06

And I think we need to make

34:06

a difference leveraging the

34:09

technologies we have in place. Think about how we can leverage

34:11

artificial intelligence.

34:13

I'm a big believer that really

34:13

can help a lot in this context.

34:17

And using artificial intelligence

34:17

for the good here and making

34:21

the world more sustainable.

34:22

Wow. Great. I think this is the first podcast

34:24

I've recorded where we've talked

34:28

a lot about ai, where no one

34:28

has yet mentioned ChatGPT.

34:32

This is, this has gotta be a

34:32

record, and I've just gone and

34:36

ruined it by mentioning it. Okay. Okay.

34:42

Listen, Hans, if people would like to

34:42

know more about yourself or any of the

34:46

things we discussed in the podcast today,

34:46

where would you have me direct them?

34:51

They can look me up

34:51

at LinkedIn, right, Hans Thalbauer.

34:54

They can also send me emails at

34:54

UiPath [email protected].

35:01

Superb. Hans, that's been really interesting. Thanks a million for coming

35:03

on the podcast today.

35:05

Thank you.

35:06

Okay. Thank you all for tuning into this

35:07

episode of the Sustainable Supply

35:10

Chain Podcast with me, Tom Raftery.

35:14

Each week, thousands of supply chain

35:14

professionals listen to this show.

35:18

If you or your organization want

35:18

to connect with this dedicated

35:22

audience, consider becoming a sponsor.

35:25

You can opt for exclusive episode

35:25

branding where you choose the guests

35:30

or a personalized 30 second ad roll.

35:34

It's a unique opportunity to reach

35:34

industry experts and influencers.

35:38

For more details, hit me up on

35:38

Twitter or LinkedIn, or drop me

35:42

an email to tomraftery at outlook.

35:45

com. Together, let's shape the future

35:46

of sustainable supply chains.

35:51

Thanks. Catch you all next time.

From The Podcast

Sustainable Supply Chain

Welcome to the Sustainable Supply Chain podcast, hosted by Tom Raftery, a seasoned expert at the intersection of technology and sustainability. This podcast is an evolution of the Digital Supply Chain podcast, now with a laser-focused mission: exploring and promoting tech-led sustainability solutions in supply chains across the globe.Every Monday at 7 am CET, join us for insightful and organic conversations that blend professionalism with an informal, enjoyable tone. We don't script our episodes; instead, we delve into spontaneous, meaningful dialogues about significant topics, always with a touch of fun.Our guests are a diverse mix of influencers in the field - from founders and CxOs of pioneering solution providers to thought leaders and supply chain executives who have successfully implemented sustainability initiatives. Their stories, insights, and experiences are shaping the future of sustainable supply chains.While the Sustainable Supply Chain podcast addresses critical and complex issues, we aim to keep the discussions accessible, engaging, and, most importantly, actionable. It's a podcast that caters to a global audience, reflecting the universal importance of sustainability in today’s interconnected world.We are always eager to hear from our listeners. Your feedback and suggestions are invaluable to us, helping shape the podcast into a platform that truly resonates with its audience. Feel free to reach out via email or connect with us on social media to share your thoughts, ideas, or just to say hello.Subscribe to the Sustainable Supply Chain podcast and be a part of this crucial conversation. Together, let's explore how technology and innovation can lead the charge in creating more sustainable, responsible, and efficient supply chains for a better tomorrow.Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

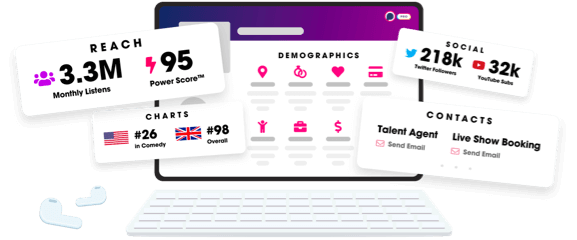

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us