Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:00

Mark: Where we fail in the trades is our journey people don't want to give that back to the apprentices coming in. We all know they don't treat them well. You're the coffee guy. You're the ladder guy. You're the, rather than take the time to say, Hey, you know what, here's how you do it and let's do it well, because they, they were taught that way. Right. And we got to get that mentality changed in our trade all around.

0:02

Trevor: Welcome to the refrigeration mentor podcast. I'm your host, Trevor Matthews, as a former technician turned entrepreneur. My goal is to really help train you, educate you and mentor you in the commercial refrigeration industry. Each week, I'm going to have top guests from technicians to manufacturers, to experts around the world to really help us grow and learn together by sharing their knowledge in commercial refrigeration, commercial HVAC and not only on the technical side, but really the professional and the personal development side as well. I'm really excited that you're here. Now let's get a conversation going.

0:04

Welcome to another podcast at the CMPX show. I'm super excited, uh, here with Mark Parliament, and we're going to be diving into some of the things that Mark has been doing over the years. He's been involved in skilled trades and the refrigeration industry. And actually today, or the last couple of days, you've been involved in the skills competition here, which we're going to dive into, but first, Mark, I'm going to let you introduce yourself. Mark: Hi, good morning. Uh, my name is Mark Parliament. Uh, got about 35 years in the trade. Um, done everything from work from the gas company all the way up to owning my own business and working for one of the OEMs. So, yeah, it's been a fun ride all the way around. Awesome. Yeah,

0:06

Trevor: so that, that's a lot of experience. So, so I know you work for some manufacturers, you own your own business. How did that journey start out for you?

0:08

Mark: It, it was really weird. Like we started, I started working for the gas company and doing stuff in Toronto and, Ended up getting shifted to, to the Ottawa branch. And while we were there, Enbridge got the contract for gassing up New Brunswick. Oh wow. And you know, one of the general manager in Ottawa knew I'd done work here as a contractor and we were teaching them how to install gas. So they're like, Hey man, can you go out and teach them how to install equipment out in New Brunswick? So sure, no problem. So they shipped me out to New Brunswick for probably about six months.

0:10

And I worked with, you know, worked with the contractors out there teaching them how to install gas and all that type of stuff. And then, uh, Came back and looked at my partner at the time and said, uh, why aren't I doing this for myself here? So I delved into opening my own business in a small town in Eastern Ontario and grew it like crazy and ended up, you know, Trevor: how was that transition?

0:12

Cause you were out there doing, you know, doing some training, working for someone else, but how was that transition at first? Mark: It was, it was difficult. I mean, it was, it was new, right? Like, I mean, when I, when I'd gone out to New Brunswick, I knew that I could do it cause I was showing them how to do it. So it was like, okay, now I got to come in and.

0:14

You know, like anybody else, I did lots of weird and stupid things at the start, but you know, it grew and it went well and everything went great. And then, uh, I actually transitioned, transitioned into teaching. So I went, I taught at Algonquin, I taught the HVAC program at Algonquin for a while. What years did Trevor: you do that?

0:16

Mark: Uh, 17, I think I did 17 or 16, 17 and 15, 16 and 17. I was there. Awesome. Um, yeah. And then, uh, I was just there as an, as an adjunct instructor. So it was only like part time. And, uh, then I got approached by one of the OEMs and they're like, Hey, would you like to come and work for us here at, uh, and, and teach this across Canada? So I'm like, sure, why not? Like, I'm always up for something new. And so I, I, I worked there and then, uh, got approached by another one that said, Hey, we'd like you to come and grow our business. So I'm like, okay. And so, yeah, I spent, uh, spent a lot of time, you know, just teaching the program, which I love, right.

0:18

I love giving back. I mean, it was one of the things when I, when I was first approached to teach at Algonquin, You know, I, I hired kids from the trade and we were at the skills competition and one of the, one of the teachers from Algonquin showed up and, you know, I kind of pulled him aside and said, guys, you gotta do better, right? You, you gotta do better. They're coming out and they're just, they know nothing. And he literally looked at me and said, put up or shut up. Yeah. And I'm like, what do you mean? He goes, if you don't like how we teach, then come in and teach. Cause we're dying for people. So, you know, don't sit and carp from the cheap seats, come in and actually put your money where your mouth is.

0:20

So. I looked at my partner at the time and I'm like, I guess I really can't say no. I mean, I can't, if I, if I want to change, I got to be part of it. I can't just sit on that, sit on the shoulders and, and complain about it. So that's what got me into teaching. And I realized I, I absolutely love it. It's, it's just my passion. And, uh, you know, I've gone, I love it so much. I've actually gone back to, gone back to university in my old age and, and got my master's of education. So it's just, Yeah, it's, it's been a, it's been an awesome journey throughout the whole, my whole career.

0:22

Trevor: Yeah. And that's it. I really believe, you know, the more you learn, the better you become. A hundred percent. And then when you can really teach someone else to be able to do that, you learn even more. It's unbelievable. Oh yeah. Teaching.

0:24

Mark: Yeah. Even when I taught, like, you know, I, I tell my students, I learned something every day. Like if I'm not learning every day, I'm not happy. And it, and it's, it's even something where I think I know something. You know, completely, really well. And then all of a sudden a student may come in and have a different look at it and go, but have you thought of that? And I'm like, no, no, I haven't. And that makes total sense. Right. And it's like, okay, I'm, you know, I'm going to steal it and I'm going to, you know, I just look at it differently.

0:26

I'm like, you're right. I didn't, you know, it is what it is. And I mean, you know, I have a good friend that's, that's in the States, David Harrell, and he's taken from me, you know, cause you know, my, my thing is everybody talks about. You know, all refrigeration and guys, it's compression cycle refrigeration. No matter how you look at it, if you break it down to the basics, it's the basics. Like whether it's an air conditioner, whether it's a reach in, whether it's compression cycle refrigeration, like you just, you can't be scared of it. It's it's the basics are the basics. If you know the basics, then you understand what condition the refrigerants in at any one spot, then you know what's happening, right?

0:28

And if you understand it and, and being able to break that down for a student, so they get. You know, what is super? What is sub cooling? Why is it there? Why do I have it? What, what's it about? And, and it's just, it's amazing. Like watching those students just all of a sudden click, you know, like you're watching, you're sitting in front of them and you just have that, that deer in the headlights look and then you start explaining it to them and then they, they just go, Hey, wait a minute. And then they're able to, to put it back to you. And you're like, exactly. I perfect. You know, I had, I had one student that's like, I'm never going to get this. It's just. It's blowing my head up and everything else and blah, blah, blah, blah, blah. And he went, went home for the night and came back the next day.

0:30

And he goes about three o'clock in the morning, it clicked. And then he just walked me through it. It's like, here it's this and there's that. And I'm like, you got it, brother. Trevor: Yeah. Yeah. No, that's amazing. It's funny. You bring up David Harrell. We used to work together, David. So he's a great guy out there. He loves educating and helping others.

0:32

Yeah. So, so that's awesome. So let's talk a little bit about the skills competitions you've been involved in because that's what you're passionate about teaching, but. to like a skills competition takes it to the next level. Mark: It does. Um, and, and it, and it, it, it's, it's difficult because as a teacher, you're, you always want to teach, right?

0:34

So when, when you're at a competition and you have the students there and, and you have to realize you've got to separate yourself, right? Like you've got to, you know, and, and, and I, it's been so hard for me. And when we bring new, new judges on, like you're, you're like, Literally having to go up and drag them back and going, it's a competition. You can't teach. We know we want to, we want to, we want to be that guy, but we can't. Right. And, and it was actually my partner that, that got me into it. Like I was, I was part of HRAI. I was just a member and I was doing lots of different things and they needed an extra judge and they're like, Hey, would you mind coming out and doing this?

0:36

And I'm like, sure. I got nothing to do on a, on that week. Sure. No problem. Right. So, so I came out and I started doing it again, the same way I love teaching. I fell in love with this and it was, now it's like, oh, okay, well now do you wanna be on the committee? I'm like, uh oh, okay, sure. I'll be on the committee. Right? Yeah, yeah, yeah. And, and being able to give back and, and to, to, to spend all the time. I mean, it, it's a lot of work, don't get me wrong, but it, it's fulfilling work and it's, and it's a great time being able to come up with doing something different every time. And that, and that's what we strive to do, is that it's never the same competition any, however we do it.

0:38

So it's, it's completely different. Um, and, and it's great. And then. You know, it works. I've been doing that for, uh, almost 18 years. Um, some of them have been there, you know, 2025. So it like the, the, the core group of the committee has been a very, we work well together and things go great. Um, so that, that's been awesome. And then last year skills came to us and said, Hey, listen, the, the, the guy that's doing the refrigeration side of it wants to retire. Would you guys take that on? And we're like, uh, okay, sure. And, uh, you know, next thing I know, they're like, uh, Mark, guess what? You're the new chair of the refrigeration committee.

0:40

So, Hey, have fun. Go for it. Okay. Well, Trevor: yeah, so what have you learned? So you said 17 years, you've been involved in 17, 18 years, somewhere in that. So how does, from starting 17 years ago to now, how has that evolved? Cause I'm sure there has been an evolution in the, in it. So, Oh,

0:42

Mark: a hundred percent. Like, you know, we, we started again, most of the time we've been doing it. It's been on, on the heating side of it. Bye. So, you know, we've done, you know, we, we have different manufacturers put stuff in and, and it's just sitting down and all the different things we've done with it, like, you know, troubleshooting and, and, you know, wiring, you know, when we first started, we had, we had furnaces that were donated by Lennox that we actually put faults in that had switches on them.

0:44

So we could, you know, a student would come in, we'd flip some switches and they'd have to try and troubleshoot what was wrong with it. And then, you know, other manufacturers have donated other stuff. So we've done like this year we did a gassing and venting portion of it and we've done, um, Other times where we've, you know, we've put screws in ventor motors and all sorts of things just to try and make it more difficult for them. So, you know, it's evolved, you know, as new technology comes out, the new ECMs one year, uh, one of our, one of our donors gave us stuff that is, uh, it's, it's all the web based app stuff. So they had to actually commission the furnace using the app and doing it through the web and all that type of stuff. So it really does change every time.

0:46

And, and. You know, even this year, one of the, one of the students after the, after the competition come up and they went, you know, our instructor said it wasn't going to be anything like this. They said it was going to be this, that, and the other. And I said, well, you need to go back and tell your instructor. It's never the same thing every year. Like we change it every year. So just cause we may have done wiring last year, doesn't mean we're doing wiring this year or next year. And I said, and newsflash, we're not doing installs at skills. So, you know, it's even more difficult. So, yeah.

0:48

Trevor: And I think that's good. That's makes it, champion. You know what I mean? Understand any situation out in the field that you can, you can take. So 17 years ago when you start doing the skills, have you noticed a difference in the competitors? Like, cause the world has changed in the last 17 years. Technologies, phones. Have you noticed any differences on how, uh, they were working on systems then compared to the technicians now?

0:50

Mark: Um, sadly yes. Um, what, what we're finding is, And this is, this is a mark. I'm not, you know, I'm not trying to bad mouth anybody. It seems the, the schools now are, are dealing on just trying to put numbers through. And not, there's not the quality of the, the instructors or of the students that are coming out anymore. Yeah. It's more of a numbers thing. Okay. And, and where, you know, years ago, Uh, a lot of the instructors would put a lot of extra time with the students to try and get them prepared. Um, we're finding they're not doing that anymore. And the teachers aren't, the professors aren't willing to put the extra time in to come to this.

0:52

So we're actually finding it's tougher to get the post secondary students to actually come because the teachers don't want to get involved. Trevor: And it's

0:54

Mark: tough. Trevor: Yeah, and I've seen the same thing. But what, what, what is is because I know for sure I work with lots of contractors who would love to have more trainers on their team to train their teams.

0:56

Are schools looking for teachers who have the skills to even teach, not only the technicals, but the teaching skills? And I'm seeing more and more schools not paying enough to have a skilled refrigeration technician do the proper treating. Because I could go out and make 140, 000 a year, and then you go to school and you're making 65, 000 as an instructor. Is there have any comments on that and how we can help change that a bit or something?

0:58

Mark: Exactly. And that's the biggest part. It's a numbers game, unfortunately. More, more universities and more colleges are relying on that part time instructor because they don't have to pay them the same. They only have to pay them for, you know, when they're in the, in, in with the students. So they get away with paying them a lot less. So the instructor isn't as invested in the student anymore and they're cutting back. You know, I know of a couple of colleges that have open positions for full time instructors that they're just not filling

1:00

Trevor: because Mark: it saves them money on their budget, right?

1:02

It's all about, it's all about money for them. So they'll, they'll have. You know, 30 adjunct or part time instructors that they only give eight to 10 hours a month or a week to, and they'll only have two or three full time instructors because then they've got the benefits and everything else they have to pay. So, you know, sadly, until we can get that changed, um, and that goes right back to, to, to high schools, right? I mean, we need to change how we look at getting people into the trades. And until we do that, it, we're not, we're not going to change it. I mean, you know, for years. We're at skills. We used to do something we called the showcase, which was the, you know, the first day of skills, we had all the, the, the, the students, the, the secondary students and, and some of the just grades tools would come in and they'd sort of walk around and we'd have little symposiums that we talk about different things.

1:04

And at one point, you know, my partner was talking to somebody, um, at one of them and, and the students stopped to listen because she was explaining, you know, here's, you know, here's what it is and you know, this is what you can do. And when you get out of it, this is sort of the type of money you can make and blah, blah, blah, blah. And, and literally the mother. You know, the kid was standing there listening and the mother grabbed the kid by the shoulder and said to him, you're too smart to be in a trade. Come on, we're not, you're not staying here. And it wasn't until my partner said, Oh, he's too smart to be making 150, 000 a year. The mother stopped and she's like, what are you talking about?

1:06

Says, well, you know, you get in there and you with overtime and, and, you know, putting the right, getting to the right place and, and all of that. And you can do that without having, you know, a half a million dollars in debt from a university course or anything else like that. And the, and the mother's like. Talk to me more. And, and, you know, I, I liken it back to the, to the day when, when I went to high school, I mean, we had the two streams back then where we had the, the, what we called the, the not smart students. They were sent to the, to the trade type school. And then we had the smart students that went to the, went to the university stream.

1:08

And, and then, you know, we, we had that disconnect that it's the, it's the dumb kids that go into trades. And, and I remember myself, I mean, I'm, I'm a, I'm a licensed sheet metal mechanic as well. And, you know, I remember in high school, I was like, you know, saying to my, my high school teacher, I will never use trigonometry. I don't, this is the dumbest thing I've ever learned. I, I'm going to leave here. I'm going to forget it. There's, I will never use this ever again in my life. And I, you know, it's just, I don't know why I'm learning that this is just, I, I, I'm never going to do it. I'm out. I'm just throw it away. I'm done. And, and you know, first year trade school, I'm like, man, I really wish I'd paid more attention to trigonometry.

1:10

Cause. You know, trying to take something flat and making it into a three dimensional piece is there is a lot of trig in that. And it's like, hello, like, you know, wow. You know, and, and just, and again, even on the refrigeration side, understanding the psychometric chart and understanding all of that, like there's, there's a lot of math and high level stuff that's involved in that to understand, you know, you know, Watson and all of it. And, and we don't, we don't think that we just think, Oh, You know, every, when you, when you talk about the trades, everybody thinks of, you know, Bob, the mechanic from 30 years ago that adjusted a carburetor or did this and you know, just anybody, Oh, I'm, I'm a mechanic today. And, oh, but, but nowadays, I mean, even a mechanic, it's they're, they're, they're computer experts.

1:12

Like they work on computers every day and how this computer talks to that computer and, and, and we're getting there now with, with digital stuff. And, and, you know, furnaces are now there. It's all computers and understanding. You know, yeah, you can be a parts changer. You can go in and go, okay, I'm just going to keep changing parts until it starts, or I can take the time to learn it and start to say, okay, you know what, let's, let's figure out what's wrong with it. Let's actually figure out what's wrong. Change that part and move on. Oh no, let's just sell them a new furnace. Cause I can't figure it out. Right. Then it's, it, for me, it's just, I'm passionate about it. Right. It's crazy.

1:14

Trevor: I totally agree with you. Like we're math, physics. English, like all these stuff we have to be very skilled at if you want to do well in our industry and it and you can take your career to a whole nother level, but when you're in high school, like the teachers don't think that, you know, you're going to trade and you don't need to know all this stuff. There's a lot of you need to know more of this than half the college degrees out there, right? Exactly. And people don't understand that. And so I like that you brought it up. So I was over at the skills competition, um, yesterday and walking by there and I noticed on the refrigeration one, they had a bunch of heat pumps and I thought, This is awesome.

1:16

This is something different. And I bet a lot of them were surprised to see that. What do you have any thoughts on that? Mark: Well, and that's it. And, and what, what we try to do. And I mean, you know, as you know, here in Ontario, we have, we have two streams. We have, we have a, and we have, we have three 13 D and, and part of when I, when I took it on and because we're here at, at CMPX, I said, what, what a prime opportunity.

1:18

Cause we, we do all the stuff at skills. We do everything for the A stream, right? Everything is about true refrigeration, but we don't do anything for. That that D stream where they can, they can come and partake and be part of it as well. So even though my, my a ticket lets me do the stuff that the D's do as well, like I can do both. So why not open it up and do something different? I mean, everybody right now, heat pumps are the new or the new gas furnace, right? Everybody is pushing heat pumps and understanding them and putting them in and all across Canada. So my thought was, hey, why don't we do something that allows more people to participate.

1:20

Get more people involved and, and gives them something different. So for me, it was a, it was a no brainer. We went out and we were, you know, one of our, one of our manufacturers or two of our manufacturers were gracious enough to donate brand new equipment to us. So, you know, we went around and we were able to pull it off and the students just, by the end of it, you could see that, you know, we had one student that sort of showed up and they, Felt that they were overwhelmed and they were like, um, I'm out. I'm, I'm just, I'm, I'm going to walk away. I just, I, I'm not, I can't do this. Um, and one of our judges took her, took them aside and just said, Hey, you know what, um, why don't, why don't I just walk you through it? Why don't you just get some experience and you, you know, I'll tell you how to do it. You just do it.

1:22

And they were like, okay. So, you know, the judges walked them as okay, well, you need to do this and you need to do that, you know, run this like that and make sure that it's this way and do it, they were one of the only people actually got a unit running. Even though they were ready to walk away and they said, I can't do this. They sat down, they, they took the instruction. They, they got the knowledge that they could do it. And at the end of it, they were so elated with themselves that they were able to do it when they were ready to walk away. And, and for me, That was, that made the whole day perfect for as much as the, the, the kids that did it and got it running.

1:24

That's awesome. They did it on their own, but this person was willing to say, I can't do this. And then we showed them, yes, you can. Trevor: Yeah.

1:26

Mark: You just need a little direction. And that's where I find where we, we fail in the trades is our journey. People don't want to give that back to the, to the apprentices coming in. You know, that first, second year apprentice. We all know they, they don't treat them well. You're the coffee guy. You're the ladder guy. You're the, rather than take the time to say, Hey, you know what, let's, let's, here's how you do it and let's do it well. Because they, they were taught that way, right? They were that, you know, we got to do it and we got to get that mentality changed in our trade all around.

1:28

It's like, we got it. We got to get them to start understanding that just because we're teaching that next generation, that's okay. Like they're, I, I'm not, I'm not going to be able to get down on my knees when I'm 85 years old. So why would I not pass my knowledge on to the, to the next generation and, and let them be as, as good as I can, I can be, right? Like to me, it's, it's just, it's a no brainer.

1:30

Trevor: I love that story because a lot of the refrigeration mentor programs that I put on people come in and that's one of the big thing is confidence. They're like, man, I'm out there. It's overwhelming. I don't have anyone who wants to help me. It seems like. And then I came to the program and they got a huge amount of time to come back and they show me pictures of the jobs that they did that they wouldn't do because they felt overwhelmed and they want to walk away because that's the people that are hanging around with and they're not sharing it. So I love that you brought that up. And that's a great story because they could have, even the judge could have let them walk away, you know, and I bet you that happens out there. But the judges here did not let that happen. So let's just walk you through it and you know, get that. And now they're going to be unstoppable out in the field.

1:32

Out of that person. And now they got that confidence to be like, well, I don't work on heat pumps, but I work on refrigeration, but now I can install a heat pump. It's just refrigeration. This, I did a talk yesterday on convert, you know, transferring from HVAC to refrigeration. Like you said, it's all the same. It's the, the fundamentals are all the same. Might have different components, might have different actual electronics, but if you understand the flow, the electric, the, the mechanical side, it's the same. You know, is there more? Yes. Is there sometimes more complications? Yeah, but. When you get down to the fundamentals, it is the same.

1:34

Mark: Well, that's it, right? It's, it's, it's getting them to understand that it, it, you know, it's, you really can't go wrong if you, if you can learn those true fundamentals and it, you know, it, it, I, I laugh one of the, one of the OEMs I work for, um, is an American, it was an American company. And as you know, down there, there, there's a lot of states, it's, it's a bit of a free for all, right? Like I can wake up tomorrow and hang a shingle out and I'm a refrigeration mechanic and Hey, I'm golden. And, and you say about building the confidence. One of the programs we ran was exactly that. It was. guy that basically knows nothing and teaching him how to become a, a productive member of the team and, and being able to watch them where they showed up day one and where they left, you know, day 21 and just the difference in the technician when they leave.

1:36

And then, like you say, we've lots of stories where we get, you know, photographs and I'll look what I did here and look at that. And I'll look, look, I'm now, you know, A year later, I'm a lead mechanic now because I, you know, what, what you guys taught me and I'm able to bring it back and, you know, there, there's always that fight. Oh, well, you know, the, well, yeah, okay. That works in the, in, in the book, but it's not really, there doesn't really work in the real world. And then you start to show them and you, and they're like, oh, okay, yeah, I guess it does work that way. Right. Like, like you say that the fundamentals are the fundamentals and if, and science, science can't go wrong.

1:38

Like if you rely on the science, it's a fact, right? It is. The refrigerant has to be in this condition, in this state, or, or it's not there. Like, if I have a, if I have a SuperEat, I know it's all vapor. I can't have any liquid in it because, you know, it's, it's, I wouldn't have SuperEat if there's liquid left. Like, it, it, it's, it's a fact. You can't be wrong with that. And, and they're like, uh, and then just that light bulb moment for, moment for me is what it's all about.

1:40

Trevor: Hey, I want to take a minute to talk about the upcoming refrigeration mentor learning programs. Every couple of months, we continue to roll out live instructor led sessions by subject matter experts on compressors, supermarket refrigeration, and CO2 refrigeration. We're really here to help you grow. Get to that next level. Head to the Refrigeration Mentor webpage, refrigerationmentor. com. Check out the events page. There's a compressor masterclass, there's a supermarket refrigeration program, and there's a CO2 program. There's also free trainings, free workshops.

1:42

Really check them out. See if this interests you. Read a little bit about it because we're really here to help you. Now I've got a question for you. So in Canada we have some great Red Seal program, you know, across the country. It's three, four, five years depending on where you're at. Um, But what I've been noticing and seeing that there's a lot of people being held back with their skills because of that. Do you believe that every technician needs to take five years to get their red seal? Or could people be trained within a couple years to be at that five year level? Or have you ever noticed people are being held back by doing flipping belts and filters all the time? Or just cleaning coils for two years straight?

1:44

What are your thoughts on that? Mark: I,

1:46

Trevor: I, Mark: I firmly believe that, that you don't need to do the, the, the 9, 000 hours to be a mechanic. You, you can, there, there are people that for sure, I mean, they need, there's some people that are very methodical and they, they for themselves need to spend, you know, a year as a, I hate to say it, as a belt changer just because, you know, but there's other people that pick up on stuff very quickly.

1:48

And, and for me, if they can, if they can turn around and they can show, not only do they, and, and, and maybe this is where we fail, is we, our, our industry is, okay, well you, you do the, the, the apprenticeship. You do the hours, and then you just go in and write an exam. And if you pass the exam, here's your, here's your red seal. You're, you're a technician, right? Where. Again, the OEM I worked for, we had, it was a practical and a theoretical. So if you can show me that you have the practical skills to do something and you show me you have the theory because you can pass the written test, then why do you need to spend all the hours doing the apprenticeship?

1:50

You show me you have the skills to do it. You can pass that practical part of it and you can pass the written. You should be able to go forth and, and, and be a technician. Yeah. Right? And, and we don't do that. I agree with you on that. Trevor: Because I'm working with some, uh, some contractors. And with some, uh, with other people that are forward thinking like that.

1:52

Is like, I believe there needs to be a system in place. That four years, because most people aren't on the path to be able to be a journeyman in one or two years. But there are a lot of people that can, if they show and prove That they can go out and a rack is down or change a oil separator or, or, you know, change a condenser on their own, that they can do something a lot faster and really help the industry grow quicker. Instead of people being four or five years flipping belts and filters, and then all of a sudden they got to go do a service call them the contracts. Well, I don't want to pay this person 40 an hour, but the contractor had them doing belts and filters for four years and they didn't really learn anything.

1:54

And there's a lot of people that I see leave the industry. Because they're putting that situation where all I do is clean condensers or all I do is change filters and I want more summons on them for not asking maybe to, I want more challenge but I've, I've seen a lot of that in the industry. Have you, have you? 100

1:56

Mark: percent and I, I was just going to say that. I mean that is, that is the problem as I mentioned earlier on with, with, with our apprenticeship style is that some journeymen won't teach. They just, you know, your job is changing belts, you're just going to do that for the next whatever and I'm not going to give the, the, the, the apprentice even the opportunity to learn, right? And I mean, I remember back in the day when I started, it was go do it. Like, okay, great. Uh, you know, first time I stood in front of a, a, a, a, a boiler, you know, in an apartment building at three o'clock in the morning and there was no heat and it was minus 40 outside. Yeah. There's nobody I can call at three o'clock in the morning.

1:58

Like it's like fix it. Or, you know, so, you know, there, I, you just had to do it. Right. And, and you learn, you, you, you muddled your way through it. Yeah. It took me three times longer to get where I did, but I figured it out. Um, but we're not even giving apprentices that opportunity to try. it's like, no, no, you're a belt changer. Just stay in your lane. You know, you're not going to do your thing and, and, and I'm going to do my thing. And that's, you know, never the two shall meet. And, and we need as our industry to start pushing people to do more, get them outside their comfort zone. Yeah. I'm, I'm, I'm comfortable as a belt changer.

2:00

That's great. But I need to shove you outside your comfort zone because that's where you learn. And even, even in training, I mean, you know, we mentioned David. We, we fed off each other because we, we like to shove each other outside our comfort zone because it was, you know, we, we learn better when we're not doing that same thing day in and day out. So it's like, no, no, you're outside. We're going out here where we're, we're not, we're not comfortable to be. And we learn so much when you're, when you're in that, that non comfortable place,

2:02

Trevor: do you think that could be changed in the industry where like doing filters and belts is not a part of. Say that skilled trade and it needs to be done, but could that be segregated to a different type of training where you hire someone for this, that specific job and it's not actually part of the skilled trade, you know, I know it needs to be done. Exactly.

2:04

Mark: I mean, we, and we look at it. I mean, there, there, there's so many out there that are, that are sort of like that already, right? Like we have, We have, um, uh, facilities maintenance technicians now that go out and, and work in apartment buildings and do that. They do belts and filters and all that type of stuff, right? So, why can't we have something like that within our trade? That is like, okay, well, you know, you wanna, if that's what you wanna be, then we call it that, and we allow them to do that, right? But I think it, it's that pushback, and it, it's no different than we look at the 313D trade, right? When, when we first, we had all those residential mechanics out there doing air conditioners that weren't licensed.

2:06

Yeah. And, and when we brought out, when we first thought about the trade, you know, the mechanics and everybody else in the unions went, Whoa, that's our job. You can't be giving, well, we don't want to do that work, but we're not going to give it away. Yeah. And it's like, Yeah. But you can't have it both ways. We got people that are not, that are not doing it legally. They've been doing it forever and they're doing it right. And technically they're not doing it legally cause they'd never going to work on a chiller or a rack. So why would they go and learn that when I'm never going to do that? And we went to the trade and said, Hey, you know that we can do this.

2:08

And there was that big pushback. You know, it's, it's kind of like the industry I'm in right now, you know, I hate the way it is, but God don't change it. Do not ever change it. Cause you know, I'd rather sit here and complain about the way it is and have to learn something new and have it differently. Right. Like it's, it's ridiculous. So for me, it's like, yeah, we, we need to take that stuff. That's, that's really not trade specific and, and I'll do respect changing a belt or changing a filter is nothing to do with our trade.

2:10

Trevor: Yeah. Mark: It's really not. So why aren't we having something within that business unit? That is the filter and, and, and belt guy like that, that PM guy, make that, make that his thing

2:12

Trevor: and, Mark: and get more people out doing the work that we really want to do.

2:14

Like, I'll tell you right now, I don't think there's a kid that, that, that goes through school or goes to the apprenticeship and says, I want to be a filter and, and, and, and belt guy. That's all I want to do in my trade. But then they get out and they try and learn. And they're like, no, no, that's Daniel. Ain't that you're not there yet. You're not there yet. Like, you know, like, you know, I, growing up, I was always that. Yeah. You know, I had big elbows. Somebody get out of my way. Let me do it. Let me do it. Get out of my way. And, you know, and, and they're like, Whoa, Hey, I'm not perfect. I've, I've blown some stuff up in my, in my career.

2:16

There's no doubt about that. But at the end of the day, at least I've tried. Yeah. Right. And that's always been my way. And there's a lot of people out there, but we hold them back and we say, no, no, no. And they don't speak up because when they do, they get stay in your lane. It's not, that's not you just stay. So they give up. And like you say, they walk away. So they've spent, Three years in the trade and they just say, enough's enough. I'm, I'm out. It's not worth it. And they go and do something else. Right. And we need, we're dying for people right now. I mean, we, we can't change. We got it. We got to look at it differently, you know, and, and in my humble opinion, taking a 15 year old out of high school and saying, Hey, go into the trades.

2:18

Now that ain't the answer. It's not, not in, not in the way that the trade is today. Can you imagine a 15 year old kid going out to a job site with a, with a crusty old mechanic that. He'll chew them apart, spit them out, and the kid will run away crying. Like, and, and no disrespect to the child. I, I wouldn't want to put my child in that, in that environment. So for us to think that's the way to do it? I'm not sure that's, that's the smart way.

2:20

Trevor: I think we should be targeting older people as well, like, uh, for sure. Because now they've already had a career. 000 struggle for it. In an office maybe, or in some sort of labor job. And just not, not being able to make it. And then taking someone that's at that level. Already understand they got house and they got mortgage, they got kids and you can take someone that has a 50, 000 salary for the last five or six or seven years or even 70, 000. And then in a couple of years, cause they're going to be motivated. I have, there was a guy here already and he was in his mid forties and he's like, I'm just starting in the HVAC program.

2:22

I already did 25 years as a, um, a millwright or a welder, he said, but I'm getting into the HVAC industry and he's motivated. You know, he's motivated where a younger person is like, okay, well, I don't know what I want to do with my life. And this So there's all over it. He's going to be studying harder. It's going to be looking for opportunities and he's going to be putting the work in there. And then you take that 50, career in a couple of years, a hundred to 150, 000 a year. That makes a huge difference for a fan. But there is that sacrifice and that scared that, that, you know, um, being scared to make that shift, that jump.

2:24

Mark: And that's the big thing, right? It's that fear of doing something where I have to go. And, and, and sadly we, we, we, And, and I, I don't, I don't want this to sound disrespectful to anybody, but sadly our part time programs aren't necessarily at the same level that our full time programs are at. So, we, we have some students that are going to these part time, these part time programs where they try and work all day at something else and try and learn the trade after hours and that. And, and we don't, we don't necessarily get the same quality quality. of people out there and they drop out too. I mean, in the, in the skills program this week, the, the, the week we've been here, we've, there was probably four or five, you know, had come and, and second career. I mean, one was a paramedic that just realized, I, this, this isn't for me as a paramedic.

2:26

I just, it, it's not what I want to do. So he turned around and, and has started the HVAC program. But, but having to leave and not make any money and go back to school full time. Now, now you've, you know, Now, now I can't make my mortgage. How do I know? So it's, it's more difficult for that. So in, in my humble opinion, we need to find a way to do more of that, that work around and, and it's tough to have, you know, a guy go out and find an apprenticeship in the, in, in the three 13. Like it's, it's, it's difficult. I mean, you know, the union only does, you know, I think it's two, two intakes a year. Um, they're not looking at the 50 year old guy that wants to retread. They're looking for the, that 20 year old kid that's going to spend the next You know, 30, 40 years in the trade and be with them.

2:28

Right. So it's a, it's a balance. We've got to try and figure out how to fix because we're just not doing it. Trevor: Well, I know for sure. There's going to be a massive amount of people looking for work over the next five to 10 years with the AI coming in and there's going to have to be re skilling and retraining.

2:30

So this is an opportunity for our industry because it's already happening. We see becoming a bell just laid off, like over 4, 000 people. I heard, you know what I mean? Like, what are you doing with them? You know, where are they going? Like, this is an opportunity for men, women. To do a second career where they can make a huge amount of difference in their life, in their life. Could you imagine going from that $70,000 a year job to 140,000 in a few years, or 130 or 120? That's, and people don't understand that it can happen and they can do it because anyone can do our trade, anyone can do it. There's lots of people, oh, you can't do our trade. But if you're, you take the training, you spend the time they're taught properly, you can do, it's like anything, a hundred percent.

2:32

Mark: And, and, and that's our biggest problem, unfortunately. It's, and, and you hit it on the head, it's being taught properly. And we're not. And, and the apprenticeship program we have right now, we're not teaching them properly. They're, they're going to the three years of trade school, they're learning in eight weeks, and they're doing their thing, and then they're being put out into the field, and they're just not learning properly. And it, and it's difficult.

2:34

Trevor: Do you feel, cause I hear this a lot, and this is all around the world, I talk to people, people come into the, the schools, and they, they only have one day a week maybe sometimes, or they do just eight weeks, they have an eight week session, or, or whatever, and And then the, a lot of, I hear from the schools, a lot of contractors think that they should be learning all the skills in the school in Yeah. In like 500 hours versus the 9,000 Yep. Say, say a thousand hours versus the 9,000 hours or 8,000 hours that the contractor has. Have you seen an issue with that contractors aren't doing their job training their people?

2:36

Mark: Absolutely. And, and you're right. And that's it. Like they, they understood, they believe. That he should be learning everything there is to learn about the trade in, in trade school and then coming back and doing it in the field. And that's what I say about our journeymen aren't, aren't the people, because really, as you said, I, I can't learn it in eight weeks. It's not possible. There's no way I can learn the fundamentals.

2:38

If I, if I really put myself into it, I can, I can get the fundamentals in there, but I learn in the trade from my journeymen and our journeymen aren't either willing or able. To teach properly. And, and that's our problem. And, and I don't know, is it, as you mentioned, some companies are like, well, I want to hire a trainer. Well, you got a great journeyman that knows this stuff that may just not be, you know, can't haul that compressor around anymore. Can't, can't do that work. So why aren't you making him the trainer to teach these students how, how to bring them up now? Now he's there. That's his job. Like it's not about, well, you know, because, and, and there's, I've, I've seen it and I've heard it so many journeyman.

2:40

Well. I can't teach him because then he'll know as much as I am and now they'll get rid of me and keep him because he's cheaper and he'll be able to do the same thing I do. So I'm not passing my knowledge on to him because that, that's going to guarantee me a job. It's not how our industry works. It was never designed to be that. And yet that, that's what it's become.

2:42

Trevor: That'll never change. And this is not all contractors because I know some contractors that have great training programs. So we're just talking to the majority that, and I keep hearing it because I was talking to a bunch of, uh, instructors today is like, I only have them for this amount of time. And then at the end of the four years, the contractors call me back and saying, they're not where I need them to be. I'm paying them journeyman rate, but they're not journey. They're not there. Well, what did they do for the last four years? And they're like, uh, they washed condensers and change belts. So you're, you're supposed to learn how to drop a condenser on a roof, you know, by changing belts and filters the whole time or anything like that, or install your own walk in box, you know, that you've never done before.

2:44

But now that you're journeyman, you know, you're getting higher paid because they work through the system, getting, getting through just changing belts and filters. Mark: So, no, exactly. And we've, we've got to, and we've got to look at how, how our trade is trained all around. And, and I and, and I, I'm not sure what that magic bullet is.

2:46

Refrigeration, mentor . Sure. Absolutely. I mean, for sure. I mean there, there is, there is places out there that do that. But even, even refrigeration mentor can't do everybody. That's right. So we've gotta look at how do we, how do we change the, the, the whole vision of what our apprenticeship is? How do we get that mindset to shift to being, this is the way we need to be. Because you're right, everybody is how, how can he make me money? He's making, okay, well, he's a, he's a 50 year now. He's got to be able to go out and start making me more money. And, but I haven't invested, I, I haven't invested any money in him to get him where he can invest money in, where he can now make me money.

2:48

I, I've got to get that, that owner to get that mindset change to say, I need to invest in my employee rather than do that. And, and part of it, and again, I'm not, I'm not bashing union or anything else, but part of it is that union mentality where, okay, you're not working out, send them back to the union. Give me a new guy. Just get rid of them and bring me a new guy. And, and that happens out there. It's not right, but it does happen.

2:50

Trevor: Yeah. Mark: Right. And, and we need to say, no, no, we need to invest. We don't, you know, I liken it to a garden. Do you put a guard, do you, do you put a garden in the ground and never water it?

2:52

Never look at it, never weed it. And then expect what, well, why don't I have great, why is my garden growing? Like I don't, I don't, I ignore it. Like I just like, why? And, and yet that's what we do to our trade. We put them out there and we just ignore them. It's like, okay, well it's five years now. Why, why can't you put a box in? Well, cause I've only done filters and things and nobody's ever taught me that.

2:54

Trevor: Washing cases. Cause there's lots of different examples of it. And I think we just, all of us need to do a better job and take a bigger look at it. And it's not only here. This is a global thing. I've talked to people all around the world and everyone has similar issues. Um, uh, because at the end of the day, you We take care of the planet, you know, refrigeration, you know, this is why we're doing all these nice things and we're talking on this stuff is because of refrigeration, right? And I keep telling people that. And I think we're hopefully learning a little bit as we continue to grow.

2:56

And I see contractors starting to understand. But they're, they need to be trained as well because they don't, they don't, they sometimes some of them look at, Oh, this is an expense. Yes. Your technician is an expense, but they're your most valuable salesperson to make your the most value of money. This week I was in Pittsburgh doing a training, teaching technicians how to make more money. And how do you make more money? You make the contractor more money. You know what I mean? And how, and you know, you build that relationship with the contractor. So both of you win, not just one side to win. And I see a lot of one sided win. Because as a technician, you do have a job to go out and do your work.

2:58

So it doesn't matter if it's 50, 60, 70 hours a week, you don't own that company anymore. If they paid you for your 70 hours a week, you went in, you did your work and then now you get paid for it and that's it. That's their business transaction. But what do you do more than that for the business? Can you pull in another a hundred, 200, 300, 400, 000 into that business? There's a potential, that's bottom line profit, there's a potential to make more money. And so getting business owners to understand is getting the technician to understand it, and that motivates them to work harder.

3:00

Mark: Exactly. And sadly, um, you know, and, and I see it so much in our trade, is that, you know, it, it's all about the side hustle. Well, I, I can, well, yeah, we got to stop thinking about the side hustle. We got to start thinking about, you know what, do, the more I, and, and, and you're right, it's that symbiotic relationship of, Getting the owner to understand that, you know, if this technician can make me more money, I need to pay him more money.

3:02

So it's a win win where a lot of them look at it and say, no, no, you just make me money and I'm going to keep rolling it in. And that's what I'm going to pay you. And I'm just going to keep scooping it in. And then the technician goes, well, why am I doing this? Why don't I just go and do it myself? Like, why, why, why would I give more name? I'm not getting anything out of this deal. I'm making him a ton of money and he's just raking it in and I'm not getting anything until we can get everybody to understand Like I said, owners need to understand if I can invest in my employee, my employee can do better. And I gotta get the employee to understand if I invest in the company, the company is going to do better for me.

3:04

Trevor: So Mark: if we can get that relationship better, we're not going to have the guy out there going oh well, here's my card, call me after five and I'll, I'll slip over and do that work for you instead. No, let's put it through the company and everybody wins with that, right? I, I was a firm believer. You know what, when I, when I go home, I don't want to do it again on the weekend.

3:06

I get paid to do it all week. I'm not doing it. I want to go home and just be myself, right? The, the biggest joke is, you know, whose kids have the worst shoes? The shoemaker, cause he doesn't want to do shoes after hours for his own kids, right? I don't want family and friends just to call me up. Oh, let's go to, no, not doing it. Thanks anyway. Just here's, here's my company cards. Call the company and let them do it, right? Only reason I started my own company is cause there was a There was a, a, a, a hole in my, in my area. There was a, I, I saw a need. I came back and went, well, there's a need here. And, and I remember, like, one of, one of the first jobs I did at my company is I went out and quoted a job and, you know, said to the homeowner, yeah, okay, we'll be there on Thursday.

3:08

And Thursday came along and I started backing in the driveway and he was literally sitting on his deck in a, in a bathrobe, drinking a coffee, reading a paper. And I'm backing the truck and the trailer down the driveway and, you know, I hop out and he kind of looks over the paper and he looks at me and goes, you're not from around here, are ya? What do you mean? He goes, well, it's Thursday. It's eight o'clock and you're here. You're definitely not from around here because that was just the mentality of the small town. It's like, yeah, yeah, yeah. We'll be there when Thursday. Well, okay. What Thursday? So I built my company on just doing what I said I was going to do when I said I was going to do it.

3:10

And it, and it took off for me. It was lucky for me. It was, it was luck. It was. There was a, there was a need. I filled a need and my company grew. That's great, but you don't always get that everywhere, right? So we've got to get that understanding that the more I can, the more, if I can get the people to understand each other and get them to, to, to feed off each other, the company as a whole grows and we've got it, we've got to do that. We've got to change the industry as we know it. You know, we, we've got to turn it on its head.

3:12

Trevor: Yeah. And now, and why I talk about a lot of this, cause I work with a lot of the business owners and the directors of these companies, and those guys are trying to implement some of this stuff into their companies. And they say they want to pay their, their, their guys more. But the only way to pay their technicians more is that you need more money coming in and their forward thinking is like, I, I want them to make 300 grand a year. You know, that'd be great. You know what I mean? Cause that means the company is making a lot more money and these are forward think owners, service directors and, and service managers and business owners who are like, Like, we want to make them better, you know, and make the company better.

3:14

And if we can keep it in, internal, it makes it even better instead of having to do this. Cause there's a lot of people in our industry that do struggle, you know what I mean? But if they're mentored right, coached right, trained right, they can really bring a huge amount of value to that organization. Mark: But you just said it, they're invested in.

3:16

We invest in our employees, our employees learn, we communicate with our employees, we invest in our employees, our employees make us money. And the more we can, we can get that and we can get that thought process through. The better it is. But sadly, our industry and not everybody, but you know, there's a good chunk of them out there that I said there, they will, you know, beat, beat the employee like a mule and make me more money, make me more money. And I don't give the employee any benefit from that. So the employee goes, why am I doing it?

3:18

Trevor: Yep. Mark: I'm just not. So, or we say, Hey, you know what? Get me there. We'll, you know, you got to make me money and I'll give you more money, but you got to make me money first. And then when I start making more money, I'll give it to you.

3:20

And then they start making the money and they never, the employee never sees a benefit from it. So the employee goes, why am I doing it? I'm out. Right. So we, we've got to, like you say, we've got to get that communication issues. Got to be a big part of it. We've got to get them to understand that. Yes, it takes time. It's not going to happen overnight, but at the end of the day it, and I was that same way with my company. You make me more, you make more plain and simple. Like that's the end of it. Right. And, and I did the end of the year, we, we always had our party. We always did. You know, I always, I always gave back to.

3:22

because that's what it's about. For me, my company was like a family. We, we, you know, there's a lot of people that joke and say, I works not really a family for us. It was, we were a smaller company, you know, we treated everybody like our brother and sister. And did we fight? Sure. Every family fights, you know, but at the end of the day you never didn't throw an employee away because something didn't go right. You know, there's that opportunity to train. And, and, you know, I always said to them, you know, you're going to fall. That's okay. We stand you up, we dust you off, we figure out where you went wrong. We, we give you the tools to succeed and we send you out again to try again. That, that's how we do it, right?

3:24

It's not, well, you know, you, you know, well, I didn't, I didn't do it right. So I'm going to get fired. That's not what it's about. It's about investing and moving forward. Trevor: Awesome. So final question. So you've been a technician, you are a business owner. What is one tip. You could give a technician that's starting out in a career to advice to really help them, move them along.

3:26

And then the same thing for as a business owner, if you're running a business out there. So one tip that would help someone starting up in their career Mark: for, for the, for the new apprentice, get big elbows, push in, get, push yourself in, insert yourself, push your, your, your journeyman to show you to be part of it.

3:28

Don't sit back, Trevor: get

3:30

Mark: in there, be the one to say, no, no, hold on, let me do it. You walk me through it. Don't be afraid to have that, that, you know, one thing I, I, my wife can attest, I, I ain't a quiet guy. I ain't a shy guy. I'm the one that's gonna get in there. I'm gonna push my way in and I'm gonna go, no, no. You know, when I, when I started, you know, I, I became a firefighter years ago and, and I was the same way. I'm like, no, no, stop. Let me do it. You show me. I want to do it. As a new apprentice, that's what you need to do. And as an, as a, for a business owner, invest in your people. Okay.

3:32

Trevor: Like, Mark: I, I, you, you can't stress that enough.

3:34

Yeah. You, you've gotta, you want to have the right people there, and the only way to have the right people there is to invest in them. You know, I, I, I was a firm believer when I ran my company, I hired out of, out of trade schools. I went to, I went to Algonquin and I went to the place and people say, yeah, but they don't know anything. I know, but I can teach them. That's not what it's about. I want to invest in that employee. I want to teach them. And, and it was those guys that came back for me tenfold because they were willing, wanting to learn being all of it. I invested in them and they, it paid me back in dividends. You know, it's not about standing on an employee's shoulders to make money.

3:36

It's working as a team. And the more we can work as a team, the better it's going to be all around, but we've got to get that team mentality going. Trevor: Awesome, Mark. So how can people learn more about the skills competition, find out more about you, if they ever want to. learn from you or, uh, your organizations?

3:38

Mark: Um, well, Skills Ontario, uh, we do it a lot, is a lot through the, uh, through the industry. But, um, if we turn around, uh, for anybody that wants to be part of the skills competition, um, reach out to HRAI. There's, uh, uh, Andrew or Grace from HRAI are more than happy to, to talk to you, put you in touch with one of the, one of the committee members. We're able to talk to you, talk about, you know, what's involved and whatnot. We've, The show's been great this year. We've had a couple of people stop by and we're inviting them down to skills in May to come down to the skills competition, just see what it's all about and learn about it. So yeah, I mean, you know, I, I'm a firm believer.

3:40

You got invest and you get back. So this, this is how I give back to my industry is, you know, it, my, my industry has been great to me. I, I have a beautiful home and you know, it's all been paid for through this industry at one point or another. So I give back to my industry as much as I can. And that's, this is part of it. So

3:42

Trevor: awesome, Mark. Thank you so much for taking time. No, thanks for having me. I want to thank you so much for hanging out with me and the refrigeration mentor podcast. If you enjoyed this episode, please leave a comment. Let me know what were your key highlights, what you took away from myself or my guests, as well as if you have not subscribed yet, head over to Apple podcasts or Spotify and subscribe. And if you enjoyed this episode, please share it with a friend. Let your friends know that there are people who care, who want to share the refrigeration information to help them get to the next level in their career. If you have not been to the Refrigeration Mentor website at refrigerationmentor. com, go check it out.

From The Podcast

The Refrigeration Mentor Podcast

This podcast is all about training, education and mentorship for commercial refrigeration and HVAC professionals. My goal to help you develop your knowledge and skills, to master the art of refrigeration. I will have expert guests from around the world joining us. We will have different conversations on technical topic's like system troubleshooting, supermarket refrigeration and CO2 refrigeration. Featuring technicians and engineers to manufacturers and many other industry expert join us to share their knowledge and wisdom. I will have conversations about mental health, mindset, and personal and professional development. My goal is to help you become 1% better than yesterday. Let's get a conversation going!Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

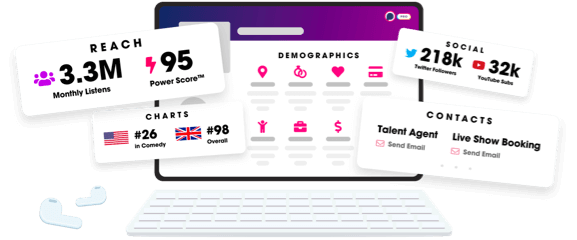

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us