Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:00

Andrew: Is CO2 safe? And of course it is. I think of when you think of that much pressure, what today are we working on that has that pressure or exceeds that pressure? Hydraulics. So as soon as I start thinking that way, I'm like, Oh man, we've been messing with this pressure all along. Just maybe not in. This type of application. Trevor: Welcome to the refrigeration mentor podcast. I'm your host Trevor Matthews as a former technician turned entrepreneur. My goal is to really help train you, educate you, and mentor you in the commercial refrigeration industry. Each week, I'm going to have top guests from technicians. To manufacturers, to experts around the world to really help us grow and learn together by sharing their knowledge in commercial refrigeration, commercial HVAC.

0:02

And not only on the technical side, but really the professional and the personal development side as well. I'm really excited that you're here. Now let's get a conversation going. Thank you so much for joining us. And I've been doing so much CO2 training lately. I've been at a lot of sites, doing startups with some, uh, manufacturers and contractors, and I thought like, I want to dive into some stuff because CO2 is coming. It's already here. It's not that it's coming. It's already here globally.

0:04

I really want to be with that mentor to help you get you through this We're going to talk about some different things that i've been seeing that i've been talked to uh, I bring a good friend of mine andrew freeberg to come in and We want to kind of just answer some questions that you guys may have some, you know Skeptical thing some of the fear that you may have with co2 if you use it if you haven't used it I know i've been working with co2 since 2015. I think i've worked on it before with subcritical but actually transcritical Since 2015. So it's almost 10 years now. This is crazy how the time goes by but Um, it's a new for a lot of people So a lot of people on here, it might be new for you. If you've been following the podcast or YouTube channel, I've got a ton of CO2 videos.

0:06

I did CO2 Mondays for almost two years every week. That's called consistency. And that's what you want to do with refrigeration. You want to be consistent and you want to learn, you want to continue to grow. So make sure you go and check out the YouTube channel, refrigeration mentor, YouTube channel. Make sure you check the podcast out. You should be listening to podcasts when you're driving. If you're a service technician, you're in your vehicle a lot. You should be listening to podcasts, growing your knowledge, getting you more confident. That's what refrigeration mentors all about building your confidence. So you're, when you're out there, you're crushing it, crushing a day in day out.

0:08

Um, Andrew, I'd love for you to introduce yourself to everyone and let them know a little bit about your background and how long you've been working with CO2. Andrew: Yes, uh, my name is Andrew Freeberg. I work at RUI out of, uh, Washington State. Currently, uh, as far as CO2, I've been working on it since I started with, about a year, about a year I've been working on CO2, yeah.

0:10

Trevor: So, when you started working on CO2 a year Andrew: ago, uh, what were your thoughts? Uh, what am I getting myself into? I was really scared, uh, uh, to be honest, the first time, um, you hear about nervous around it and, uh, when you get nervous, that's kind of when you start making mistakes. So, uh, that's why I really started to dig deep into it because being nervous about something, you start second guessing yourself, your knowledge.

0:12

And so you have to be comfortable with what you're working on. So. Doing the research on it and what I came up with is, you know, C is CO2 safe, you know, and of course it is. I think of when you think of that much pressure, what today are we working on that has that pressure or exceeds that pressure? Hydraulics. So as soon as I start thinking that way, I'm like, Oh man, we've been messing with this pressure all along. Just maybe not in this type of application. So as soon as I put my mindset towards like, Oh, we've been Messing with these type of pressures all along, then you get more comfortable with it.

0:14

And with the safeties that are implemented on CO2, it just makes it, I guess, you're comfortable. Level gets higher and higher with it. And just knowing and researching what terminology is. That would be my second thing. Trevor: And that's a big thing. This is a learning curve, but it's no different than when you start in the, in the industry, I was the first gen technician, didn't have a clue.

0:16

What refrigeration was I just thought I went to a fridge and it opened up and it was cold You know what? I mean, no clue. So I had to learn the terminology. What's a compressor? What's a tx valve so on and so forth So getting into the co2 realm, it's the same thing. There is a lot of new components Uh, and it's no different if you're in residential you go to commercial or you go to commercial to vrf for example You're working on your standard acs and packaging You go to VRF, there's lots of different things that are happening there. Electronic valves, boards, uh, different terminology. So that's one of the big things that I like, uh, that I needed to learn as well, is the terminology. Because you want to make sure you're talking about the same thing when you're talking with another technician. One of the things that I really felt at first was there's a lot of people, I think, making me worried about it.

0:18

You know what I mean? There's a lot of naysayers, a lot of people, uh, trying to put a lot of fear in people about it. Was that a good thing or a bad thing? It might have been a good thing because what I see out there today, a lot more people are cautious when working around CO2 versus the complacency people have got over the last few years. 15, 20, even 30 years with HFC. But you know what? I talked to some old school mechanics and when it first came out, like HFC systems and, you know, high voltages, chemicals, or it was the same thing. Then when I look at people, when they did the shift from, you know, the low pressure refrigerants to four 10 A, for an example, it was the same thing.

0:20

It took decades to really get people to get on board with it, and now four ten's gone. You know what I mean? So I think there's gonna be a transition time, but you need to prepare yourself just like Andrew did, and he's only been working on it for a year. And I see you got to go and follow him on LinkedIn, follow him on different social media platform. And he's putting posts out all the time to help educate you finding things on CO2. One of the big things that I see is that it's high pressures. Why does that matter? That's the question. Because if you close a discharge valve on a compressor, you're gonna have some high pressures real quick, right, if you've mistakenly done that.

0:22

And one of the biggest things that I try to teach all my students and everybody that comes in, and anybody I talk with about how many people here, let's see a show of thumbs up, who's ever used or carried nitrogen on their shoulders, in their vehicle, anybody? Everybody. I know all of you have. But do you know what, do you know how much pressure's in that nitrogen tank? Does anybody know? The one person says 800 PSI. Good grab. I think it's PSI, not bar. Um, 200 bar, 1200, 2000, 2000, 2000. It's going to be up to 4, 000. You know what I mean? And you're using this all the time. 2, 000 PSI, 200 bar, 100 bar. It doesn't, it doesn't matter. You're already, for years and decades, you've been working with high pressure refrigerants.

0:24

Like nitrogen and it's a high pressure, but we don't think about that. Now you've got the regulator on there. One gauge is 2000 PSI, and then we regulate it to 200 PSI or 150 PSI or whatever, 300 PSI. So when you start to take the concepts of what you've been working on now, and then bring it to CO2, you start looking at it a little bit differently. It's should you still be worried for sure? You should be worried with HFCs, H uh, HFOs. Okay. You should be worried with those as well. There are chemicals there, you know, there were a highly skilled trade. So you have to be safe. You got to learn the safeties of it. And when you do that, I think it's going to make you more confident.

0:26

And before you start listening to people talk to you about CO2, make sure you do some of your own research, just like Andrew did. Because you're going to have, I talk to people all the time and I've been studying CO2 for a long time. And I've been trained by the best around the world and I'm still learning. And I still go do research and I still go find out, you know what I mean? So you want to make sure you ask them, this is the questions to ask someone when they tell you something about CO2, you can ask them, have you worked with it before? Have you installed a CO2 system before? Have you started up or commissioned a system before?

0:28

You know what I mean? Ask, challenge them. And then they can, if they tell you, yes, I did 50 startups, I did a hundred startups, you know, I done this many installs, then you can take, okay, now we can talk about this, but there's a lot of people talking about it that haven't really worked on it. They hear the theoretical side of it. And they haven't really done it. Andrew, any comments on that?

0:30

Andrew: Yeah, I'm going to second that with, uh, with, with what Trevor said, um, when we switched over from our 22 to four 10, there was that transition period. Like that's too high a pressure. We're not going to touch that. But, you know, just like you said on that, um, nitrogen tank, we are already running 2, 000, 2, 500 PSI in that tank. So it's just a new refrigerant and that's where everybody's getting, you know, cautious of, I guess. If you do some research on it, it's going to take you a lot further. You're going to be a whole lot more comfortable with it. Instead of just taking someone's word. Do your own research. You have to do your own research.

0:32

That's what's going to make you excel in this trade. Trevor: I know I see a few people say I've never worked with CO2 before as first training. Say the biggest thing is that the information is out there. Do you want to learn about it? And you're going to be confident at it. And you can go, like I said, right now you can go to my YouTube channel and there's hundreds of hours of CO2 conversations, you know, same with my podcast, hundreds of hours.

0:34

You know, and you can go check it out and there's lots of other ones out there. So do your research, um, because Andrew has been working for, for a year and he's crushing it in CO2 already only a year working with it. The big thing is, is that he did the research. He did the study. People told him it's a high pressure. You got to worry about it. Well, the manufacturers today and the ones that I work with and I deal with all around the world, from Europe to North America, to Australia, to New Zealand. And These manufacturers are building them as safe as possible. They're way safer than HFC systems. And I was even in a conversation today that people are trying to add.

0:36

More stuff to CO2 system to make them even safer, higher pressure systems, like better piping, a different UL codes like here, I'm in Canada right now, and it's different than in the USA, we got to use all stainless steel at this point on the high side. You know, you don't have to worry about the high side breaking, you know what I mean? Well, it could break don't get me wrong vibration in improper installation, but if it's installed properly Uh, even if you have a leak on the high side and it's running 1400 psi a leak I've seen people have their glove on and run across 1400 psi a leak i'm not saying to do that, but it didn't cut off their fingers Didn't cut through the gloves either.

0:38

So just be aware that you want to understand Uh what to look for when you're when you're dealing you have to be safe But you have to be safe with all systems you're working on system right now that are 480 volts Could be 575 here in canada could be 380 volts if you're in europe wherever you're at That is way more dangerous than a closed system. The systems are supposed to be closed and they have pressure reliefs on all the different pipes. What, what are your thoughts, Andrew, on the safety of a CO2 system versus an HFC system?

0:40

Andrew: Well, safety is going to be. More important on a CO2 system, but there's levels of it. There's really four levels of safeties on a, on any transcritical CO2 unit, at least four, they could be more. You got the, the high pressure valve will open up when it gets too high a pressure. So there's a safety right there. So what a high pressure does, it just kind of acts as a restrictor in the high side, right before it goes into the flash tank. For people that don't know. The second level is that your controller should be programmed about 1530.

0:42

That's when the high pressure safety is going to, or the controller on. You need to Dan Foss, whatever it may be, is going to say, shut off. It's too high. If it's still going now, we got the mechanical safety. Mechanical safety is going to go up a little bit higher, you know, 1560 PSI. And then if it all comes down to it, it still keeps going. We actually have the fourth level safety and that's going to be the compressor has its own, uh, pressure relief, and then that will blow. So the chances of everything failing all at once are highly unlikely. So it's very, very safe to work on just by knowing those four safeties that are involved in this, uh, transcritical booster.

0:44

Trevor: And one thing, how many people here ever had a nitrogen day pointed away and opened it up? And just listen to the nitrogen tank blast out really loud. I know I have, and it's loud. Do it with a CO2 tank. Safely, earmuffs, you know, earplugs in, glasses, gloves on, and let it go. Just listen to it, because that's like one of the reliefs. You know, if it's 800 PSI, because on a standard cylinder, when it's average temperature, so, sorry, room temperature, it's 68 degrees or 20, 20 Celsius around, and you, you, you open it up. That's going to be 800 PSI. So that's kind of like your flash tank relief, depending on where it's located, what manufactured is it's either 650 or maybe 800 and some, but when your tank blows, that's what I look for.

0:46

So when I go into any mechanical room, it doesn't matter if it's CO2 or not. I'm looking for where the exits are. Is there a lot of junk in the mechanical room? Cause you guys know. Customers are throwing crap in there that they shouldn't be putting in these rooms and it doesn't matter co2 or not One good thing. They're a bit cleaner now than the new co2 rooms, which is pretty cool But i'm sure they'll get back to where they were back Uh, you know where the hfc ones are you go in and then I look for where all the pressure reliefs can Are they piped outside? Are they still piped inside? What's the code? You got to understand some of this stuff.

0:48

If the pressure relief goes where, if I'm beside it, what's going to happen? Is it going to just go in a pipe and go out or is it going to affect me? I've had pressure reliefs go off beside me and it startles you, you know, even after a year, first time, you don't expect it to happen and it startles you. And I've seen and I watched pressures go up on systems before having, uh, non condensables in it, and they start to flutter, and then I watch it go, and you know, it hits the 1600 PSI, and I hear the relief go, it still gives me a little startle, even though I'm watching it, and I know, know the relief's gonna go.

0:50

You have to prepare yourself, uh, for that, and get a good understanding where all the safeties are. Because worse comes to worse, What you can do if you feel it's unsafe, you go just shut off all the low temp, uh, compressor, uh, uh, breakers or dis, uh, yeah, breakers or, yeah. And then go to all the medium temp and shut them all off. Even quicker, you just go to the phase monitor and just drop out the whole rack. So all the compressors stop and we're not pumping 1500 PSI, you know, so it's a fail safe mode. This is something you need to learn and understand because then you stop that compression happening. Do you need training? 100 percent You need training, but you have to you have to invest your time just like andrew has been doing learning about this stuff So you have to be safe around it, but you have to be safe around 404 22 i've had ruptures and cut lines when i'm in a small Smaller confined space and a whole room filled up and it's white In minutes, you know what I mean?

0:52

And then it's not easy to breathe. You got to get out of there. Right? So it doesn't matter if it's CO2 or if it's a 22, this is the, the thing that you really want to understand. Chris, you got a question? Pressure release. So required replacement is, is five here in Canada by code is five years to inspect or replace. Okay. So depending on where you're at, you need to check your local code. You don't want to be, it's no different than your HFC system. Okay. So the pressure release for those ones are similar to the, the CO2. That doesn't, that code doesn't change just because it's CO2. It's still a refrigeration system and this is what I'm trying to talk to people.

0:54

It's another refrigerant. Like I can get into propane and talk about R290 and about all the risks there, but it's Once again, these are closed systems. You've been working around a threes in your house. Probably you go to your house and you check your fridge, probably are 600, you know, and you just don't know this stuff, all the, I've seen this about maybe eight or I can maybe a couple of years now. I was driving down the highway here in Ontario and we have these on routes and I just stopped to get some gas. And while I was walking through, I seen a Coke machine. I looked at the back cause I'm curious. I'm a refrigeration technician. I'm always looking at refrigeration unit. On the back, it said R 744.

0:56

I'm like, wow, R 744, and then I looked it up. Coke has millions of units that are, uh, have R 744, which is CO2. So just, just be prepared. All this stuff's been around you for a long time. We just haven't seen it, and you're hearing more about it. Anything to add to that, Andrew? Andrew: No, you're exactly right. And just so you guys know, CO2 has been around since I think the first one was like back in the 1850s, 1830s.

0:58

So we're just redoing it. So that's another thing that you guys could put that in your belt. You know, uh, it's, it's a new refrigerator, but it's not, it's just, we're just redoing it. So that's a, you know, another thing you can think about when you're looking at it for the first time. Trevor: So we've got a question.

1:00

What's the pressure at the inlet of the TXT and the outlet? So in CO2, there's only one mechanical TX valve that I know of right now is Dan Foss. I don't see any application up there. I'm pretty sure it's going to be small, small systems. They won't be in a, A supermarket application or a large industrial application, you're going to be using, uh, you're going to be using electronic valves and inlet pressure could be like, we'll say 550 PSI or 35 bar, we'll say, and the outlet pressure is going to be whatever that temperature, if it's a plus 20 Fahrenheit or minus 20 Fahrenheit, so it could be 407 PSI, give or take, so, you know, it's a couple of hundred differential, you know, low temp, it'll be a bigger differential because you'd be running around, say 14 bar, 200 PSI and a high side would be that five 50 or 500 or around 33, 34. Guest: Hey, Trevor, like you were saying, though, um, And also Andrew was saying the, the thing is, is I've been working with the CO2 for a little while as well. Um, but the thing is, is most people have to realize is that with CO2 being around for so long, the difference now is we have a lot more safeties than we did then.

1:02

As well as a lot more conscientious focus on why CO2 is a lot more necessary now also. Trevor: Yeah. So yeah, this is not new. I think back in the early, mid 80s, this uh, Gustav Lorentzen, he started to revitalize CO2. So it's, we're, we're getting, we're in 2024. We're talking almost 40 years ago. They were trying to, uh, Out in Denmark and in the Scandinavian companies, they were trying to get it rolling and it really took off over the last say 20, 20 years.

1:04

So this is still not used. There's over 70, 000 large installations, supermarket installations in Europe and around there. So there's, there's a lot and it's only going to, Start to increase very, very fast. And I like what Chris says there is it's not new. We do have to be more conscientious about it. Back then there was no, even 20 years ago, there wasn't as many safeties as there was now. And now with all the manufacturers working really hard to compete. It's just great for us as the industry that now there's more options, you know, and that makes the manufacturers better and work at it safer, uh, to develop some of the best equipment out there. And that this brings down the prices. A lot of people will say, well, it's more expensive.

1:06

It is more expensive. Okay. But the thing you got to realize is that this is the direction the industry is going, you know, this is regulations. This is environmental factors now, which is the big thing. And as a technician, you want to understand that you don't know, like I've released. Not knowing HFC is a lot of it as bad for the planet. Now these new refrigerants have more chemicals in it, and it's bad for the environment, bad for the water, bad for the ground. I don't know all the things, but I've been doing a lot of research on PFA's and TFA's, and these chemicals are bad, so you shouldn't release any refrigerant. I hear of people cutting out systems and just blasting still 200 pounds, 300 pounds out to the environment.

1:08

You shouldn't be doing that. Don't do that stuff. That, that, that's killing your kids and your grandkids, potentially, or you're harming them for sure, killing the planet. Um, that's why we, they have these rules and regulations and CO2 is just the same. It's not good for the environment. I just want you to know that right now, that it still has a GWP of one. So it's not good for the environment. You can't, people do release it. Because it's natural, there's no regulations at this point of releasing CO2, but I'll tell you now, there will be at some point, and you don't want to release it anyway, you want to keep it in the system so you don't have to add more gas, just like you do with your HFC system, get a recovery cylinder on there, and then a recovery unit on there and pump it into another part of the system.

1:10

There's lots of strategies. You got to just think, and that's one thing, Andrew, I really like about the CO2 over the last few years is that more technicians are thinking about what they're doing before acting. Have you noticed that? Andrew: Yeah. I mean, even with me, when I first started, I have to stop and think about what process I need to do.

1:12

To work on this type of system, um, I had a, just for an example, I had a evaporator coil leaking from the factory and I had to replace it. But the crazy part was when it was running and I was leak checking, you could hear this tick sound and it was actually at that triple point where the dry ice was hitting the back of the panel. And, uh, so to get rid of that, let's think about how are the process of taking that refrigerant or this. Isolating that, uh, case to pull that coil so I could replace it with a new one. That's the cool part. So with a CO2 it's, it's different. So you shut off just like you do any system. You shut off the liquid line, get everything to a vapor state.

1:14

Then you shut off the, the suction line. If pressure starts to increase, that means you still got liquid in there. So then, you know, you open it up and let it go, go out. Um, so, and then, you know, you just, Replace the coil, slap the new one in there and you pull your microns on your vacuum. I mean, that's, that's where it's really important is make sure you're pulling your 500 microns. Uh, when you getting into the system, once you pull that 500 microns, you're good to go, but. With co2, you can't just open up the liquid line because then you'll get into that triple point. Now you got dry ice in the system, so you have to think about what you're doing. So then you got to open up the vapor side, which is the suction, raise that pressure up and don't just go over there and crank on the the ball valve, you know, slowly open it up.

1:16

You don't want that hammer to happen. And then you open up the liquid line and then you're done. Okay. Running just like normal. I always double check my superheats, uh, because you just never know, but it's the same system like on in the, uh, synthetic type refrigerant. Trevor: That's the big thing. And even like you said, 500, I was at a site last week, they had it down to 15 microns at one point.

1:18

Oh yeah, just minimum Andrew: 500. Minimum 500.

1:20

Trevor: Like you should be pulling vacuums down below 200. And if you did it, right, you can do it fast way. I did used to do it back in the day through gauges, long hoses through, um, traders. It's the wrong way to do it. You can pull them down way faster, way, way faster and quicker and use the proper size pump and the proper hose. True blue hose or a big end of inficon, the proper hoses to use. It's a good question here. What about reliefs on the back of bits or compressors are in the dish? Relay in addition, basically pointing right at you. This is something you need to be aware of. They are discharged. And you know, if you hit that 2000 PSI, I can't remember.

1:22

So I think it's 135 bar. When you hit that, they're going to open up right in your face. You, if you check the system and tested the system, those high pressure controls should cut that out first. Realistically, and even before that, if that high pressure valve doesn't cut it out, your pressure relief on the roof should cut it out. Will they go? Can they open up? They totally can. But you do, as a technician, have to be cognizant of that. But in HFC systems, I've seen reliefs just pipe right off the receiver right into the rack room, not piped outside. So it's a similar thing. You walk by that receiver, not thinking about it. So it's happening in there.

1:24

So you do need to be cognizant of it. And depending on where you're at, it's mandatory to pipe it outside. All those. Here in Canada, certain places, you can't. You can't have those reliefs, David, inside the mechanical room. They have to be piped outside. So it all depends on the code and the local, uh, jurisdiction. But that's, that's a great point, David. You gotta be cognizant of those. So another one, when removing gas from isolated coil, I think Andrew just asked that, uh, answered that, you know. If you do get dry ice in the system, and it can happen. A lot of people talk about it too much, like it's a big worry. If you do it right and you're trained properly, you shouldn't have to ever worry about dry ice.

1:26

But Andrew, if you've got dry ice in a system, what could you do to get rid of it? Andrew: Somehow you're going to have to raise the pressure. I honestly never gotten Dry ice before, uh, because I really, with CO2, I just stop and think about what I'm doing before I do it. Um, I've been working, doing this for, you know, man, almost 20 years now.

1:28

Um, and you know, the HFC type refrigerants or whatever, you just go in and you just start cranking things because that's just, it just comes natural. CO2, I actually have to stop and think about what I'm doing because I don't want to mess up. But what you do is you just bring the pressure back up, get it above the, I think it's 61 PSI. As soon as everything gets above that triple point, that's when. Everything will start turning into a liquid or a vapor, like what it should be. Yeah. Like four to a

1:30

Trevor: 4. 2 bar. The big thing is, is that if you do get dry ice in there, you can increase the pressure where find another port somewhere else, what you don't want to do. If you get dry ice in your hose. Okay. And a blockage happens in the hose. I've had it happen before that you need to make sure that you don't let it go. You hold on to it. You close it until it shoots out because it's going to shoot. That block is going to shoot it. If you have pressure behind it, even if you close the valve, the heat up, as you increase the temperature, increase the pressure.

1:32

So just be cognizant of that. Anytime you're putting refrigerant in, just like Andrew said, you've got to get that vapor pressure up above the triple point. Some people say 100, 150 PSI or 10 bar, seven to 10 bar with vapor. So just understanding these things, that's going to lead to a better working system and you're working safer. That's just doing the understanding. And this, this, all this stuff is in all the manufacturer's manual, you know, they explain all these safety guys, cause they're, they're cognizant of it too. They want you to be successful out there. I talked to all of them, you know, I know most of them and they want you to be successful out there and they're doing their best, but it's coming fast at them as well.

1:34

Fast at the end users. I hear a lot of blames going on and complaining out there in industry, but all, not only the contractor and technician, but this has happened to the end user. It has happened in the manufacturers. People aren't, you know, some people aren't prepared on how fast the change has happened and lots of people don't like change. So that's another thing you should be someone in the refrigeration industry who embraces change because change is coming to our industry and We're not we're the best industry out there. We're the high top skilled in it There's no other skill trade out there that can do what we do. We do controls. We do refrigerants.

1:36

We do chemicals we do Plumbing we do everything Okay, so we do it all electrical, so we need to show the other industry and the other skilled trades that we can handle change. And when I talk to other, because one again, to come back to the pressure, when we talk about pressures, I talked to other industries more like 2000 PSI, we work with 100, 000 PSI. Like that's, we don't even deal with it. There's something broke if we're running at 2000 PSI. So just to understand that. So if you do get dry ice in the system, you can add pressure. Sometimes you, you can't do anything about dry ice though. I've seen situations and talk with technicians where the valve is, is jammed closed.

1:38

Okay, so they have to isolate it in one place, isolate it in another place, and they have to slowly get the pressure out and where it caused dry ice. And it does happen, but it's very far and few between. I know technicians work on hundreds of stores, never cause dry ice. Hey, I want to take a minute to talk about the upcoming Refrigeration Mentor Learning Program. Every couple of months we continue to roll out live instructor led sessions by subject matter experts on compressors, supermarket refrigeration, and CO2 refrigeration. We're really here to help you grow. Get to that next level. Head to the Refrigeration Mentor webpage. Refrigerationmentor. com check out the events page.

1:40

There's a compressor masterclass. There's a supermarket refrigeration program, and there's a co2 program There's also free trainings free workshops Really check them out. See if this interests you read a little bit about because we're really here to help you These live sessions are for you to come and ask questions, to learn a little bit, to grow. We've trained thousands of technicians from technicians from three to four to five years in industry, all the way up from 20 to 30 years in industry, either get them to the next level or get them back on track. Do you think sedentary will capture industrial chiller markets from HFC, HFO? It all depends on regulations.

1:42

CO2 is growing massively in the industrial space. Let's see already. It will continue to continue to grow in chillers. I don't know. We're going to see a push by other natural refrigerants like propane, uh, and a few other ones. And we're going to see a push from chemicals like the HFOs to try to maintain that space with lower GWP, but there's regulations right now, say in New York, they're trying to push for a 10. GWP limit, then there's no refrigerant, but naturals at this point, there is like the one, two, three, four Y Y F I think, and the one, two, three, four series that are, I think one or two GWP, but besides that, there's no other refrigerant that are down that low, like the ones that they're pushing and moving right now for the air 54 B.

1:44

So start, if you're in air condition right now, start learning about that refrigerant, learn about the glide, learn about the differences. The compressors have to be changed. They get different. Uh, they have to design them a little bit differently because that refrigerant and chemical compounds move differently through a system. So they have to build different, uh, different standards under bearings and inside the components. Compressors do the same thing, but they have to add stuff to it. So as you add complexity to, uh, like the, the new refrigerant there, it's more complexity to the system. A lot of people say, well, what about A2Ls?

1:46

Well, fine. Great. A2L is no problem. If we got to work with them, my, my goal is to help you guys as technicians out there be successful. It doesn't matter what refrigerant is. It could be ammonia. It doesn't matter. It could be old school refrigerants. But what I want you to do is if it, whatever refrigerants thrown at you, you can work safely at it. But lots of people say, well, A2L is. You know, it's more price competitive. Well, when you take in the factors, depending on where you're at and all the leak mitigation, all the leak detectors, depending on the size of the box, you might have to have a fan and have dampers that open up the box so you can mitigate all the air in there because of the square footage and the size of it.

1:48

And then now do we. We need to be trained more once again, it all comes back down to training, understanding what you're working on at hand. We got drives, VFDs, controls. These are big things that you need to start learning today, but it's not only the refrigeration side or CO2. We see this VRF, VRV systems. We see it in HVAC commercial one, BACnet. We're seeing, you know what I mean? Control, building control systems. The advancement of it is happening throughout our industry. You want to be ahead of that curve. Don't be scared of learning something new. I see this time and time again, people, my program, and they're like, well, I've been in the industry 10 years.

1:50

I was talking about, have you worked on a drive on a compressor yet? No. Have you seen one? Yes. Why not? That's because you walk by this stuff and I did the same thing. I did the same thing. The big thing is if you see that stuff there, be curious about it a little bit more. Dive in and learn about it just a little bit. Thoughts on that, Andrew.

1:52

Andrew: Well, first off, I want to talk about the ATLs. Um, ATLs are, are definitely here currently, but I think it's going to change because they do have that higher global warming potential. And what I've seen on the biggest restriction is the quantity. You can only have, I think, up to 50 pounds. That could be different in, in Canada, but I think you can only hold up to 50 pounds of, uh, Any A two L out there, it's a hundred and

1:54

Trevor: that's, I think it's 167 pounds. Um, and then now they're trying to change it to where it's a, my understanding it's a, it is 167 pounds per system, but they want to change it to where it's 167 pounds per circuit. So that would mean a lot bigger system. So a lot of things, I don't know that there's still conversations going around on that, but I don't know, I'm going to have to learn a bit more about it, but yes, the charge size is, it makes a difference if it's a small store, you know, like a 7 11 or that may work, but then your state may not, you know, may not approve it.

1:56

Andrew: And then on top of that, I actually heard, I was talking to an individual in Texas and they actually, the fire marshal actually made them put water cannons. Thanks. On top of the roof, just so that they could, uh, if anything happens to it. So there's another extra added costs to that. So, I mean, with CO2, it's not flammable. So you don't have to worry about that. So that's definitely where he at is going to, it's going to be huge on costs on startup. So just make sure you do your research on if, uh, on any system that you do, especially when you're starting it up from scratch or brand new.

1:58

Trevor: And here's a great question. I get this all the time. Andrew, you've pumped down a co2 rack before. Yes. How long did you have to work on that co2 system? Because people are like, well, if I pump it down, I got 10 minutes. And then, man, those reliefs are going to go. Like, how long have you had a system down for pumped down, shut off?

2:00

Andrew: Yeah, I had to shut off for hours and no problems. Um, also I do live in Seattle, so it is a little bit colder climate than maybe let's say California. Um, but no, it definitely takes a little bit of time for that pressure to start building. And, um, it really depends on your, your reliefs. Um, so I think advancer, if I remember right, has a, I guess, a dual setup on pumping down, let's say, if you have to do a repair or anything on a unit.

2:02

Um, you could actually switch that, uh, pressure relief from 650 to 800. So that's something to be aware of too, if you're ever working on a system that you need to pump down for whatever reason, but typically you're going to have, you know, a couple hours and, you know, and even if you have a system that has a, um, Auxiliary auxiliary cooling, then time is really, you just force, get that thing on. It'll cool the liquid refrigerant in the gas cooler, or excuse me, not the gas cooler, the flash tank, and now you got all day, all night long to do your repairs. And, you know, we can't have a store shut down for that long. We usually get it up and running by then. So that's something else to take in consideration.

2:04

Yeah. And if you have a power outage, your backup generator will be able to run that, at least it should be sized to run that, uh, auxiliary, uh, cooling system for your flash tank. Trevor: And this is the thing that I said, cause in the States, there's not like I train a lot of people across the U S there's not, not a lot of auxiliary units.

2:06

Do you see a lot on your systems, Andrew? Andrew: No, but I

2:08

Trevor: questioned why here in Canada, I think every system I've been to has one. Everyone, because it helps with, if you want to work on a system, you just turn it on, if you want to pump down the system faster, you have an auxiliary, you just turn it on and it makes the flash tank colder and you can pump down quicker. You can even use it. Uh, uh, there are different ways to use it as well. Um, the big thing is that understanding those systems that you're working on. So you've got time. How long does it take to do a coalescent filter change on a H uh, HFC system? If you're prepared, probably an hour, two hours, a couple of hours, That's more than enough time to do it on the same thing on the CO2 system.

2:10

You might have a few more bolts depending on the size, but if it's the same size, it's going to be about the same amount of time to do it, as long as you know the process. And you're going to get quicker and faster as you work on these systems more. Andrew: I want a second on, on the changing out the, like say a liquid filter.

2:12

Um, the only thing that I would recommend is pumping down the rack before you do it. The reason why is because you want to know where your liquids at, because that's where your expansion is going to be. If you have it on a sales floor and let's say, you know, something happens and you blow a line, you're not even going to know about it. So it's best to keep where that liquid, where you know, exactly where that liquid. For safety reasons and just give you a peace of mind too.

2:14

Trevor: And I was taught, the guys in Europe taught me that years and years ago. They're like, Trevor, we just want you, everyone to pump down. I know times of innocence, you know what I mean? Like you got jobs, you got, you got calls holding, but it's better to do that job right the first time, get it done. And then, then move on because just like Andrew said, if you don't know where that refrigerant is while you're working on what, what could happen, right? So it's, I, I still recommend pumping it down.

2:16

Um, you, you guys will learn different ways to do it over time as you work on more systems. There's smaller systems, there's bigger systems, they all work a little bit differently. So you got to understand what you're working at, at hand. What's the average cost of CO2? I don't even know. Two dollars a pound, Andrew? Five dollars a pound?

2:18

Andrew: Yes, it is. Really, really cheap. I think we're a little over 2 the last time I had to charge a system up per pound. Trevor: Yeah. Try to go buy like 454B somewhere. You go to a wholesale right now, I bet you don't even have that stuff yet, but that's what you're going to go and put in systems.

2:20

That's just messing with everyone. But prices of refrigerants are going to go up. It's crazy. So just be prepared. How do you recover and move CO2 to another part of the system? You use a recovery, uh, unit. You can use a re if it's vapor and you can just move that through there. You want to make sure that that recovery unit can handle whatever pressure you're putting through it though. That's the big thing. Mostly just say you're pumping down a circuit and you have a, you have some gas left in it and just say it's a long run, but you got a lot of gas in it and you only could get it down to 200 PSI, the lowest you could get it down to because that's your low temp, uh, suction. You could put your recovery cylinder on there and pump the rest of it out at that pressure.

2:22

If you've got a big loop system or something, if it's a small thing, most people are just going to go outside, bring a long hose and bleed the rest of that outside. If you have to work on the coil. Uh, but keep most of the CO2 just like HFC in that system. Do not try to, you know, blow most of it off because more people do that, then somebody's got to go back and charge it. Okay, in New Zealand, we're currently buying a 11 kg 4 4 jug for 4, 600 New Zealand, 2,

2:24

Guest: 800. Whoo! Trevor: So 11 kilograms, about 30 pounder, 2, 800. Well, you can get CO2 for 2 and 50 cents a pound. U. S. Um, that I would, I would, that would be a main driver for me. So the question is, is like, that's one of the main drivers in New Zealand, why they're pushing because refrigerants so high.

2:26

And that's, what's going to happen here. That's it. I see the price like people keep telling me the price is like their customer can't afford a massive leak. Some systems have 5, 000 pounds, 10, 000 pounds of, uh, refrigerant of like R22. And they're just like, we have one massive leak. And then that cripples the, not cripples, but it's, it's a smash to the bottom line. I saw droplets of dry ice when purging, they evaporated their day. My liquid was removed. So that shouldn't have been a concern. But like they said, reinducing suction gas to the system. Yes. 100%. Anytime you work on an evaporator, change an EV, you clean a strain or whatever it is. On that one, the process is to open the suction first, get that 200 or 400 PSI, get the soap out and then soap, whatever you weld it.

2:28

So you see two, two and 400 PSI, you're going to should see bubbles, right? You should see bubbles. If you missed that leak, then if it's a still, it's still a leak blow or you get rid of that, you take that out, put the back pump on and pull it down. Right, because you're going to pressure test first, gotta get that out, and then put the back pump on. And people are going to say, well, why would I do that? Well, there's air in that system at that point. And if you don't, the best thing is, is not to get it up to whatever that suction pressure is. Is because if there is air in there and the ball valve is leaking, it might push back through into the system.

2:30

So if it's a 200 PSI, like low temp suction, you get it up to a hundred PSI of suction. Just slowly do it, get it up to spray it, check it, get it out, then evacuate it. There's different ways to do it. Refrigeration, many different ways you can get, get the same results. What do you think, uh, Andrew, on that? Andrew: Yeah, I agree. First off, just hook up vacuum to it and double check your welds, too. Um, or solder joints or whatever. Uh, visual inspection will go a long ways for you. Um, of course, uh, if you feel like you got it, then most likely we do. Most of us, uh, that's been in the field probably know, yeah, that's a weld, or, well, nope, I'm gonna have to redo that.

2:32

Um, but for you, for you guys just starting out, yeah, that's going to be the best practice is boosts the pressure in there. Still bit like Trevor said, um, if it starts bubbling, guess what? You missed it. No big deal. Just take it out, hit it again. Test it one more time and you most likely you're going to get it the second time because you see it. Um, but, you know, you could always trust your micron gauge too, you know. Your microns, if you can't pull down, you got a leak. Or if it keeps slowly creeping up after you have everything isolated, you got a leak. It could be the ball valves leaking by too, but likelihood of that is. Yeah, I guess it happens.

2:34

Trevor: Yeah, no, it could happen, but this is why you got to prepare yourself and you understand it Good question here low temp chillers minus 80 c minus 150 c the low limit of co2. I think is minus 55 or minus 60 degrees, so I don't think it'll be doing ultra low temp That's a good question though. I should look into that a little bit more. Uh, like our two nine and 600 workarounds with two condensing units for one system. Now you can do that. Uh, lots of, lots of good questions here. There's quite a few of them too. I had a power out. Let's check this one. I had a power out for hours. No issues, 23 to 25 Celsius ambient. So I had a, I did a CO2 training, maybe.

2:36

In the fall, and I had a contractor said that he had a CO2 system shut off, fully charged for three months. All he had was the auxiliary unit running. And so as the pressure did, if the pressure did go up, stage one compressor would just turn on automatically if it needed to. But he said three months, that that CO2 was fully charged. And didn't blow, uh, didn't blow the relief. So all depends on the design. You got to understand the design. You got to get in those PNID, uh, and understand those, uh, piping and instrumentation drawings, lots on costs of chemicals per pound. What kind of oils and CO2 systems? Uh, that's a great question. So you're using a heavier weight oil.

2:38

So Bitzer's, uh, 85 pounds. So B, uh, BEK. I can't remember which one is 85. Bye. Copeland uses a 68, RL 68, and if you have both Copeland and Bitzer on a rack, go with the 85. So there's lots of, these are just little things you need to learn, um, but if you put the wrong oil in, you're going to run into issues with lubrication. That's just, just the way that travel CO2, that's very miscible with, uh, or the oil is very miscible, CO2 is very miscible with and they can, uh, really. Uh, mess up some compressors. When I first started learning about CO2, um, I was working at the compressor, a compressor manufacturer at Copeland, and I've seen dozens of scrolls come back and the same failure every time.

2:40

And it was flood back, even though you have. 10 K or 20 degrees superheat. You need more sometimes. That's why you got to understand the system that you're working on. Superheat is very important. And with these new refrigerants, there's requirements on superheat. You'll even go check out the A2Ls and these new refrigerants. There's going to be different types of glides on them where CO2 is a single blend, but All those ones are multiple blend two, three, four, five different refrigerants in them, depending on the refrigerant. So you want to make sure that you understand what you're working on. So for regular HFC, I can just ball valve off filters and change the filter go before CO2.

2:42

You need to pump down. Why is that? Well, you can do it with CO2. If there's a bypass, even with the HFC, you still need some sort of bypass to keep that system running. Like you can't just shut off the, the filter without pumping it down. There needs to be a bypass and there's lots of bypass. Like I've seen them. I was at a site last week where you can just isolate, leave the system running and change the filter. And we're not saying you can't do that. But the thing is that you really want to understand. Um, what you're working on, because if you don't have a bypass, you have to pump down anyway. Great question.

2:44

Great question. Guest: The other thing is on welds, you have to make sure that they're not just surface welds to there's people that will weld stuff and then they'll just look and look at them and say, okay, hey, it's good to go. And it'll just be a weld on top of the surface. And as soon as they put pressure on it, Pop flies apart because they've only put a surface weld on there

2:46

Trevor: and that goes with even hfc. I've seen that and I've even done it before guys. Honestly, I've done it before. I didn't when I first started brazing and welding. I didn't know how to do it properly, but yet heat up the pipe. You get it. You get it nice and, uh, cherry like, and then you get up the fitting and then you heat up the fitting and then it sucks in and then it should fill right up and practices for all the new people on here.

2:48

Practice welding. 90, most of your companies will pay for those pipes for you to practice on. They'll buy soft copper, you anneal it, you know what I mean? Not anneal it, you uh, swedge it, you put another piece in, and you braze it. And practice, and practice, and practice, and get better. Man, I did thousands and thousands of welds. And I did a lot of crappy ones. Until I got good at it. And then I understand how to properly heat the pipe up and then heat the fitting up and then suck it in properly. So great question. Thanks, Chris. Um, wrong oil. It doesn't matter. Wrong oil in any refrigeration system will cause failures. It's like, you know, you take mineral and put it in a 404 system.

2:50

It's going to cause a failure. Don't mix oils. That's right. Andrew: Yeah. A lot of, uh, yeah, you definitely don't want to make soil, but. A lot of your common practices that you guys have been doing this far definitely transitions to CO2, you know, not to mix oil, you know, not to mix, well, gas, I guess you won't do that with CO2, uh, but those common practices are going to transfer right into the CO2 system.

2:52

So basically anything from the flash tank on is all a regular rack system, just a little bit higher pressure. That's another thing that really helped me get through that, uh, I guess the scare factor of CO2, though, really that, that's it. Exactly. Trevor: And we got a couple of another good question here. Like on a regular parallel rack, if we have one compressor locked out, we can still maintain suction.

2:54

What's the response time for CO2? It's the same, same thing. You need the capacity. Right? Yes, you can shut one compressor down, but if all of a sudden you don't have the compressor, the capacity, that compressor is going to run and run and run. So it all depends on the design. So now when you talk about smaller parallel racks, you got two medium temp and one low temp, you're going to run into an issue, but it's no different. Then like an HFC single rise, a condensing unit, you know what I mean? But with, uh, with the CO2 ones, yes, your low temp will be pumped into the medium temp and that is boost. That's why it's called the transcritical booster system. It's taking that low temp discharge that goes into the medium temp suction and boosts it.

2:56

And you got to understand that low. A lot of people are all worried about this high temperature as well as well. It's like, Oh, we're in California or we're in Arizona, we're in Mexico, we're in South Africa, we're in Australia. We're worried about the heat, man. I, the more I see more issues in low ambience than in high ambience. So in low ambience to control a system, you need to set up the controls properly. When you start getting below say minus 20 out, it's no different than an HFC system here in Canada. If you don't have your head pressure control set up, probably your whole back's set up properly. Your system is going to crash out and it's the same thing with CO2.

2:58

So gotta be prepared to understand when you're, you're running in low ambient applications. Have you ran across any of that yet? Uh, Andrew. Andrew: Low ambience. Uh, actually, yes. Um, I had, uh, that my VFD, uh, was spinning my fans. To it was, it wasn't programmed right. And what was happening was my, during winter time, my liquid pressure, I guess my droplet pressure was dropping so low and it was, you could hear the VFD of the compressor ramp up and ramp down, ramp up and ramp down.

3:00

So you're trying to figure out what's going on. And then you go up in the roof and you've seen the fans banging on, banging off. When they're on a VFD, which they shouldn't be doing that. So I actually had to call the manufacturer and tell them what was going on. And we had to change the programming settings, uh, to a different setting. I couldn't, I can't tell you the exact points that I did. Uh, but we did change a couple settings and then it was permed like a kitten.

3:02

Trevor: And, and the thing is you got to understand, uh, how the systems run. I think one of the big thing is I was at a startup for a week or four days. And the biggest thing is walking through step by step and understanding the wiring diagram versus what you're working on and going through each component. It takes time. It takes longer to start up a CO2 rack. Cause there's more electronics, but if we designed a, just say another refrigerant rack with all these components on, it's going to be the same thing. It's going to take that much longer because you've got a hundred controllers, the wire up and tests and the pressure transducers and the temperature probes and the three way valves.

3:04

And it's just, there's a lot more to it with these new high tech or higher technology systems, but it's, you need to spend the time and walk through that step by step. We've got another good question here. What purity. To use for CSO. So this is a great question. Lots of people, um, I've, I've had conversations on this weekly. Like the only place that I know in the world right now that have shortages or don't have enough CO2 is in the U S for some reason, like Canada, I've never, ever heard anyone tell me that we don't have enough CO2. Maybe the reason is. Uh, the, the purity wise, but in Europe, the people that I deal with in Europe, they say they never, that I know of, they never ran into a supply issue.

3:06

So for purity here in Canada, most of the manufacturers do a 90, uh, 98. 9 or 99. 8. So it was bone dry. So it's not using refrigerant grade, not using Coleman grade. When I was down at that site, they had 60 tanks. I think it was 60 tanks of. Coleman grade or refrigerant grade. So that's 99. 99. But when we talk about if you need to get a customer up and running, you need to get the refrigerant, that's going to get you running them running. So if you have to get a lower grade refrigerant, what do you do, Andrew? Oh, the lower grade refrigerant in. Yeah. And, but then how do you do it? Use a filter. Yep. I was going to say that

3:08

Andrew: out of filter to it. Just the only thing you got to be cautioned with, uh, adding a filter is you don't blow that filter and shove all that, uh, And incandescence into the system. You're not going to like that, but, uh, but that would be the only thing is making sure, you know, the working pressure of that filter when you add it into the system and make sure you have, depending on how much you need, make sure you grab one or two filters or whatever. So, you know, it's only good for a certain amount of capacity too.

3:10

Trevor: And Greg. Question by, uh, Patrick always charged at the bottom of the flash tank. There's lots of people charging in through the evaporators and the suctions, they're not rated for that. So if they are, and I've seen a picture from Rusty Walker. I was at a training last week or a few weeks ago in, uh, Pittsburgh at the N-S-A-R-C, I think, or no, it was in Vegas. When I was in Vegas. Um, and they had a direct bottle from the, the CO2 tank, right to the suction. You can't do that. You need some sort of regulator in between there. So even if it's a hand valve where you drop the pressure down, you'd be still don't really want to put it into suction. You should be going to the flash tank.

3:12

If you do, I know people do it, make sure it's the farthest one away. Make sure that you're not blasting in over that rated of that coil. So if the coil is only rated for 600 PSI, you're going to make sure that you're not pushing it in there any harder. And then you've got to watch your superheat from down on the floor and make sure you're not flooding back. So there's lots of things that you need to be thinking about when you're charging. So, so great job, Patrick. Yeah. Definitely put it in the flash tank or in the receiver. Some people call it flash tank. Some people call it vessel. Some people call it receiver. So you do want to understand all that.

3:14

Andrew: Yeah. Terminology is huge. Uh, it is a slightly different compared to, uh, CFC type refrigerant or whatever. Um, so terminology was another big step for me, um, to know, listen to a podcast or whatever it to follow along. You got to know the terminology of what they're saying, and that's going to really help you figure out or what they're talking about and help you learn.

3:16

So first thing is, you know, is definitely understanding the terminology of CO2. Trevor: A hundred percent. And it's super important to, to learn the terminology and it takes time. And I still meet people that say new things that I don't understand. So I have to ask them, what do you mean by that? You know, what's that valve terminology that they use.

3:18

So it's important to, to take the time to learn this, invest in yourself, to learn that, and we've got a bunch more questions here. Big thing is if you spend right now, 50 hours over the next three to six months studying just 50 hours. CO2, you could go and work on it confidently, if you know refrigeration, not if you're green, but if you're already doing supermarket work, you've been working in supermarket refrigeration for a year, for a few years, you can go work on CO2 systems, right now, not, and I would say, you won't have a, you won't have too much of a problem with it, and about four weeks ago now, maybe I was at a site, Uh, here in Ontario, where it was an industrial technician, never worked in a supermarket before, never worked on a CO2 rack before, and this one industrial technician and a controls guy, because you need a controls guy that understands when you don't understand the controls itself, started up the rack on his own. Never worked on a rack before and he started up a rack in a couple weeks Okay So if an industrial guy can come down in and work in a supermarket and start up a co2 Transcriptable rack and you work on supermarket. I know for sure you guys you guys can work it I do have a bunch of courses coming up if you want to really dive in and this is you know More of an advanced course so you need to understand how to use the tools You need to know how to work on a system because, uh, if you're looking for the, you know, the introduction stuff, there's lots of stuff on my YouTube channel, but this course here is going to definitely help you get you prepare you and get you ready for the, you know, getting out in the field to what to expect, what to see, uh, because you need to start preparing for this.

3:20

You know, you have to start preparing for this because if you work in the supermarket industry, you're going to see it. Final thoughts, Andrew? Andrew: I would second everything that, uh, we've been talking about is get comfortable with it, but that's doing the research. That's taking the time out of your day and studying, you know, 15, 20 minutes a day.

3:22

That's all what we're asking and that's going to excel your career. Um, that's how, I mean, I didn't wake up knowing CO2. I actually sat down. Took the time, invested in myself to learn all this stuff. Um, so starting off, uh, you know, getting comfortable with it, start listening to the podcast when you're traveling from job to job. Just taking the time and investing. And that's what's going to excel your career and don't be afraid of it. Just be cautious.

3:24

Trevor: Yeah. So 100 percent go and follow Andrew. Go check out his LinkedIn page. Check him out. Follow him on the different social media platforms because he's sharing the content out like that. Head to the Refrigeration Mentor YouTube channel, the, uh, the podcast as well. Like I said, the 80, 90, maybe even a hundred podcasts on CO2 from designers, from technicians, from startup guys, from manufacturers, you name it. I've had a lot of different people on there. And if you know people that, that you, they should be interviewed on CO2, or you, you think.

3:26

That they have a good message to help the industry. Cause that's what we're doing here. That's why Andrew's here. That's why I'm here. We're trying to help the industry. We're trying to help you be more confident out there. So you're crushing a day in day out. You're going home in the evenings, finishing jobs quicker on the weekends, going to your kids sports games, uh, instead of, you know, stressing out. Did I fix that job? Did I not? I've been there. Did I, did I make, did I close that ball valve? You know, this is what we're trying to do is help share that knowledge. And, um, we'd love the feedback that hopefully there will be a survey after this. So, um, just fill out that survey. We did have a quiz. There's so much we talked for another four hours on this stuff.

3:28

Same with Andrew, cause we love it so much, but take the time, start learning and investing in yourself a little bit and grow that knowledge. One last thing before everyone goes, I got one other thing I'm starting. Uh, morning coffees with Trevor again. I haven't done it in a year and a half, so if you guys want to join me for a coffee in the morning, I'm going to just throw that in the chat right there. It is free to hang out with me. I'm doing a challenge for the next 30 days for refrigeration professionals to grow yourself, to get better at what you do, because this is what we do. You need to get into the right mindset. You need to motivate yourself. You need to get into good habits. We, once again, we can get.

3:30

As a refrigeration technician, we can get pretty lonely. We're eating out on the road a lot. And when, you know what I mean? We don't see our family sometimes a lot. You got to get in the right mindset. You got to stay healthy and this is what going to be morning coffees with Trevor is going to be all about. If you want to join me tomorrow morning, click that link there. Uh, and register, I think there's hundreds of people already register. And we're going to hang out each morning, Andrew. Thanks again, brother. Thanks everyone for showing up and we'll see you next time. Thank you guys. I want to thank you so much for hanging out with me and the refrigeration mentor podcast.

3:32

If you enjoyed this episode, please leave a comment. Let me know what were your key highlights, what you took away from myself or my guests, as well as if you have not subscribed yet, head over to Apple podcast or Spotify and subscribe. And if you enjoyed this episode, please share with a friend, let your friends know that there are people who care, who want to share the refrigeration information to help them get to the next level in their career. If you have not been to the refrigeration mentor website at refrigeration mentor. com, go check it out. There's a ton more guest podcasts I've been on as well as the event page. Check out the events page because there's a lot more free trainings as well as paid training to really help you grow your knowledge base.

From The Podcast

The Refrigeration Mentor Podcast

This podcast is all about training, education and mentorship for commercial refrigeration and HVAC professionals. My goal to help you develop your knowledge and skills, to master the art of refrigeration. I will have expert guests from around the world joining us. We will have different conversations on technical topic's like system troubleshooting, supermarket refrigeration and CO2 refrigeration. Featuring technicians and engineers to manufacturers and many other industry expert join us to share their knowledge and wisdom. I will have conversations about mental health, mindset, and personal and professional development. My goal is to help you become 1% better than yesterday. Let's get a conversation going!Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

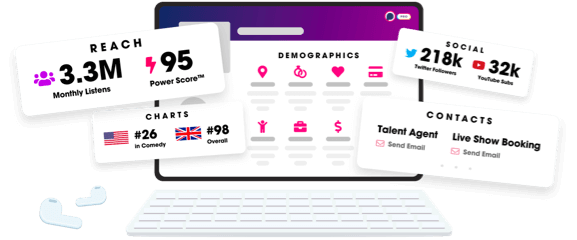

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us