Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:01

This spot is brought to you

0:04

by eaten vans. the symbol of

0:06

advanced investing. What's inside your E

0:08

T off with parametric equity premium

0:10

income? He Tf you know? Inside

0:12

you'll find institutional expertise from a

0:14

specialized team with deep derivatives experience.

0:16

Get to know what's inside P

0:18

A P I the symbol of

0:21

alternative income at Eton vance.com/symbols Before

0:23

investing a prospective investors are carefully

0:25

consider the investment objectives, risks, charges

0:27

and expenses. The current prospectus contains

0:29

this and other information and as

0:31

available. At Eton vance.com Read the prospectus

0:33

carefully before investing not have to. I see

0:35

ensured offer no bank guarantee may lose value

0:38

not insured by any federal government agency, not

0:40

a deposit. Investments involved risk, principal loss as

0:42

possible distributed by Force I Phone Services, Llc.

0:47

Hide any A Alex have you ever heard

0:50

of through the printing. Yeah, of course there's

0:52

so much hype about that a few years ago.

0:54

Yeah, Right? Like have you ever used to three

0:56

to print early to have anything made from pretty

0:58

printing? I've never used. One but I do have

1:00

like some boxes and stuff that were made with

1:03

three. the printer. And. What have you look

1:05

like? They're plastic and

1:07

there's lots of ridges. On It

1:09

because they build everything and layers over and over

1:11

and over again. Kind of like a with on

1:13

your Something Epic Records. So this

1:15

idea of depositing a material

1:18

in layers. Make. Sense for like

1:20

little things that we have at home right? that

1:22

hype around you know we're going to have one

1:24

of even every home haven't really come to pass

1:26

right? right? No Star Trek replicators? Not

1:28

yet. But it turns out there

1:31

is a really useful place for this

1:33

kind of technique which is in manufacturing.

1:35

So the technical term is additive Manufacturing.

1:37

Roka and some people are saying that

1:39

additive manufacturing could actually transforming entire industry

1:41

like a could lay the foundation for

1:43

what they're calling the factory of the

1:46

Future. Pretty. Printing works

1:48

differently than other methods for making stuff,

1:50

so unlike casting or molding which happens

1:52

when a material is placed inside or

1:54

round, something else or three, D deposits

1:56

layers of a material like plastic or

1:58

metal on top of. Can.

2:01

I know hobbyist do still use

2:03

treaty printers Machines like the a

2:05

much wider applications there used to

2:07

make parts for cars. Medical.

2:09

implants like Keith, and even

2:11

parts for commercial airplanes. And.

2:14

Aura a Stir is t across. We

2:16

have replaced a lot of conventional polymer

2:18

parts and was edited so many such

2:21

in simply because it's cheaper. That

2:24

fuck assaults he overseas additive manufacturing

2:26

research and technology at the Airbus.

2:29

Airplanes are, of course, complicated

2:31

and sophisticated. Pieces of technology so

2:33

the company can't Three different everything but

2:35

you might have written in a plane

2:37

that you just really printed parts. Were.

2:41

Also metal parts and always who

2:43

sixteen specifically in the doors and

2:45

when I say metal this means

2:47

titanium actually so it's a high

2:49

strength and there's a very good

2:52

use case and mechanism that's opening

2:54

and closing basically the doors and

2:56

this pottery could make it so

2:58

to present later. so cheaper and

3:00

manufacturing. This. Technology has also become

3:03

big money and the years since it

3:05

became popular with hobbyists. The. Market

3:07

for three D printing materials was about

3:09

seventeen billion dollars and twenty twenty two.

3:12

And. It's expected to grow to nearly

3:14

a hundred billion dollars or twenty thirty

3:16

two, according to market research firm Precedence

3:18

Research. It's biggest impact on

3:21

the future may not be those Star Trek

3:23

style replicators in our homes like we were

3:25

promised. Instead. It may be

3:27

changing how we mixed. But

3:30

the technology is still fairly new and

3:32

engineers are still figuring out how best

3:34

to use three printing and for what.

3:36

From the last return on, this is

3:39

the future of everything. I'm Alex Avila

3:41

and I'm Danny Louis. Today we're looking

3:43

at how additive manufacturing could change the

3:46

way we make everything from airplanes to

3:48

cars to houses and how the technology

3:50

could make them more quickly. And Celeste

3:53

stay with us. This

4:02

message comes from Viking committed to

4:04

exploring the world and comfort journey

4:06

through the heart of Europe on

4:08

an elegant Viking long ship with

4:11

thoughtful service, destination focus, dining and

4:13

cultural enrichment on board and onshore.

4:15

and every Viking voyage is all

4:17

inclusive with no children and know

4:20

casinos. Discover more at

4:22

viking.com. I

4:31

recently paid a visit to Rutgers

4:33

University in New Jersey where I

4:35

met with Rajiv Malhotra. Malhotra studies

4:37

new ways to manufacture things, including

4:39

with three, the printing and he's

4:41

showing me this wild thing one

4:43

of his graduate students has put

4:45

together. This is a

4:48

access is y axis and a z. Axis and

4:50

this is mounted on a roomba.

4:53

right? The a little roomba

4:55

but a mutant one. Picture.

4:57

A black disk with a bunch of exposed

5:00

circuit boards on top of it, along with

5:02

a spool of bright blue plastic fiber that

5:04

plastic seeds into the nozzle of a three

5:06

the printer attached to the back of the

5:09

robot vacuum. So. It leaves a trail

5:11

behind it as it trundles around on top of

5:13

a medal table. Not. Everything went

5:15

according to plan though. The. Roomba

5:17

started moving but the printer wasn't

5:19

working. Down

5:24

right now I've been Nesterovic is one

5:26

of Malhotra graduate students. here

5:31

of hop and are able to maneuver

5:33

without any issues. A

5:35

few minutes and one internet cable later,

5:38

the roomba was ready to print. Finding

5:45

out where it is, It

5:47

is touching the base and point where I'm

5:49

that it's going to start. Consistent

5:52

as much. As

5:55

we watched the roomba drove on top of

5:58

the square of bright blue plastic about two

6:00

feet long on each side. It

6:02

was about as thick as a couple of credit

6:04

cards and was made from the same stuff coils

6:06

up on that spool attached to the robots back.

6:09

As. The roomba slowly moved onto the square,

6:11

more that plastic was laid down behind

6:13

it on top of the sheet. Kind

6:16

of like a slime trail left by snail. Plus.

6:19

Lead was printed, one little mobile on the

6:21

table and the second live was printed. it

6:23

climbed back. And is printed at.

6:25

Night. Momma. Just

6:28

as the reason for the roomba

6:30

is to make additive manufacturing more

6:32

adaptable, he says a mobile printer

6:34

that isn't constrained by a box

6:36

could allow future printers to build

6:38

larger and more complex objects. Wanna

6:41

make them bigger and bigger? Meeting the machine

6:43

bigger and bigger. Vivid eventually will make something

6:45

the size. It's roots. You have to buy

6:47

something. Bit of industry has hundreds of thousands

6:49

of dollars. In fact,

6:52

sides with the limitation that Haka shots

6:54

in charge of additive manufacturing airbases said

6:56

with something that could make this technology

6:58

more useful for his company in the

7:00

future. The. Technology makes a lot

7:03

of advancements. Machines are getting bigger

7:05

and more productive, so additive manufacturing

7:07

becomes more and more robust, becomes

7:09

more and more and stand the

7:11

technology and it's more and more

7:13

easy to implement. It. This.

7:15

Is something that lots of companies are

7:17

experimenting with in their industrial processes minus

7:19

the room bus. Being.

7:22

Able to use a bunch of three

7:24

printers to make lots of small parts,

7:26

whether they're prototypes, molds, or tools for

7:28

factory workers to use. One. Of

7:30

those companies his forte. The. Maker

7:32

of the Mustang and the F. One fifty. When.

7:36

Our clients here in North America.

7:38

we have probably over seventy three

7:41

print to help make ergonomic aids

7:43

operators to hold pops in a

7:45

better way to get higher quality

7:47

to use for spare parts for

7:50

equipment. And they can do it

7:52

very quickly and they can you to receive li

7:54

prototype. That's. Adrian Price.

7:57

Easy Executive Director for Global

7:59

Manufacturing Engineer. The Ford Motor Company.

8:02

He. Says the Automaker has been using Three

8:04

Be Printing to design and produce cars for

8:06

decades. If. You go back to

8:08

the value chain. Every Ford model that

8:10

we make in North America. That.

8:13

Car was either touched by a sweetie

8:15

pretty pop or a sweetie printed part

8:17

was used to develop the prototype for

8:20

it. Or. As reedy printed part was

8:22

used to make a tool to help make it.

8:25

Price. As Three Printing Corp Additive

8:27

Manufacturing whatever you want to call it,

8:30

Is becoming a larger part of the factory

8:32

line. But. There are some

8:34

challenges. this technology still nice overcome.

8:36

One. Of the things that were working on

8:39

obviously is, how do we scale that

8:41

and get it way more efficient at

8:43

much higher production volumes? How do we

8:45

get to three hundred and seventy five

8:47

thousand parts coming out of the process

8:49

right? Cost efficient way. For. The

8:51

most part price as forty is a standard

8:53

three d printers. For. Large projects.

8:55

The company's engineers often make multiple parts

8:58

and stick them together. Records.

9:00

Professor of Achievement hooks us as the

9:02

Roomba project is one way to solve

9:04

the problems of speed, size, and efficiency.

9:07

Good idea. To

9:10

six years is to be able to

9:12

say he have an army of these

9:14

three four five of these working together.

9:17

To be small, small that is such

9:19

a small. Small sections add up to

9:21

bigger pipes and not all of them

9:23

working together. So that now

9:26

you can build a. Heart

9:28

that is bigger than each individual

9:30

robot on each individual additive manufacturing

9:33

the ship. If multiple printers

9:35

mounted on a room bus or something

9:37

like them. Can. Work together on

9:39

something larger than themselves. That. Could

9:42

open the gates to larger and more

9:44

intricate three d printing projects. Turning.

9:46

Each robot into what Malhotra calls a

9:49

tiny factory. And. Whether you're

9:51

building a tool to make a car

9:53

parts or the part itself, Malhotra says

9:55

additive manufacturing has the potential to be

9:57

a lot more precise. Lasagna,

10:00

The good example of additive manufacturing

10:02

actually read be few I'd sees

10:04

you are tomato sauce and all

10:06

of that rights three months same

10:08

thing in added many sanctioning. We

10:10

can add different materials the different

10:12

layers of different locations. We can

10:14

leave. Space as out live, we don't

10:16

need them. And. Set of

10:18

carving a solid block of metal to make

10:20

a mold for a tool. For example, a

10:22

three pointer or a team of robots could

10:25

just make the tool itself. Saving.

10:27

Time, Materials and money.

10:30

On. The flipside. Relying. On just

10:32

one machine could mean big problems if

10:35

something breaks. One. Of the

10:37

issues with additive manufacturing is there's

10:39

a lot of chances for to

10:41

go wrong. Right? You're adding material

10:43

point by point. If you're adding

10:45

fifty thousand points than a good

10:47

gambler, know how many chances you

10:49

have of screwing that up? Rice.

10:52

A lot bigger part Beagle

10:54

France. And potentially losing time

10:57

and money that three printing was supposed to

10:59

save in the first place. To.

11:01

Prevent a three d printed object from

11:03

falling apart like a poorly made lasagna.

11:06

Malhotra. Showed me another project one of his

11:08

graduate students is working on. A

11:10

device that acts like a self correcting

11:12

inkjet printer. Of

11:17

the status Assess assess.

11:21

It. Was a really small error. But.

11:23

As we was on a close up camera scream.

11:25

A. Gap. A fraction of an inch appeared

11:28

between two lines of plastic. Attend

11:32

the properties of the dogs right?

11:34

It's a don't want to know

11:36

it's correct itself. As we

11:38

spoke. The. Gap sealed up. The.

11:40

Freshly printed plastic was once again being

11:42

laid directly next to the previous line.

11:46

This. Was just a demonstration, but Malhotra says

11:48

even a small error could permanently week

11:50

and a three d printed object. You're

11:53

putting pieces of lasagna on top of each other's

11:55

You need the cheese to stick their to begin

11:57

to be right if you don't have it and

11:59

then you'd start. The read it. it's like a

12:01

bad sandwich just for the past. That.

12:03

Same inset printer has other abilities

12:06

to. A rak that allows

12:08

for up to fourteen different nozzles to be

12:10

used at once, unlike conventional thirty printers, would

12:12

only have. Malhotra. Showed me

12:14

a few different objects the students had made with this

12:16

device. Multicolored. Objects made

12:18

from a variety of plastic filaments.

12:21

Each. Of these, the others

12:23

corresponds to a difference. Extruders

12:25

Two different printer said that

12:27

I did one section Luzon

12:29

section Bronzes All of them

12:32

are printed Epicenter. Just

12:34

like a home printer has separate cartridges for

12:36

different kinds of that. Making.

12:38

A three The printer that can mix

12:40

different materials the same way an inkjet

12:42

printer mixes different colors. Could be a

12:44

step towards having a single printer that

12:47

can make complex parts out of multiple

12:49

materials all in one go. The key

12:51

is to be able to do it.

12:53

Didn't enough scale. For

12:55

different applications with enough materials you

12:57

did of control. We need

12:59

to be able to do this across the

13:01

board. Or. When Ford can make

13:03

an added the remaining factored engine. En.

13:06

Masse then added to would realize it's to

13:08

pay. For. Now though,

13:10

Price. The Ford engineer said his company

13:13

is mostly looking at the future of

13:15

thirty printing and making small components and

13:17

tools not entire engines, but engine parts.

13:20

There's a limited amount of materials that

13:22

we can print at this point. some

13:25

more materials with broader properties because you

13:27

know. Reason why we use

13:29

allotted for materials in automotive in

13:31

Africa vehicles as we need for

13:34

specific property of that particular material

13:36

based on what is function is

13:38

right from in Syria parties sits

13:40

on to a suspension component pot

13:42

has to be very lightweight and

13:44

but also very robust. Plus.

13:47

He says additive manufacturing just isn't fast

13:49

enough for a company like Fort. If.

13:52

You take an F One fifty. Were

13:54

making one of those every fifty eight

13:56

seconds, right? So that's a lot of

13:58

volume A traditional manufacturing methods work. There

14:00

are those kind of things and so to

14:02

me this is more about you know, picking

14:04

the right tools. For. The job right.

14:06

Can't eat soup with a fork and in

14:09

the same way we have to think about

14:11

what is the right tools that get us

14:13

the most efficient. But. Some

14:15

researchers are already trying their hand at

14:17

some larger scale applications and making a

14:20

factory of the future. They sing consoles

14:22

These challenges. Alex has more

14:24

on how that could work after the break. Believe.

14:32

It or not, Summer is just

14:34

around the corner. Luckily, Armor All

14:36

America's most trusted auto appearance brand

14:38

has what your car needs to

14:40

get that perfect summer shine. Plus

14:42

now you may thirty first will

14:44

give you Five dollars for every

14:46

twenty you spend on Armor. All

14:49

products. That means car wash, pods,

14:51

protected tire Shine, you name it.

14:53

Find out how to get your

14:55

five dollar rebate at Armor or.com

14:57

Armor or Less work more Clean!

14:59

Term Supply. In

15:09

aura know mean there's a house unlike any

15:11

other I've ever. Seen. Since

15:16

a fairly small one bedroom. About six hundred

15:18

square feet. With kids and living

15:20

room and bathroom. It's got a front

15:22

porch and lots of natural light. Oh,

15:25

that is pretty normal, but there

15:27

are details to give away it's

15:29

uniqueness. Like it's distinct curved walls

15:31

and ceilings. And they're made of

15:34

a woody material that I've never

15:36

seen before, this ridged and deposited

15:38

in layers. Prepared. High

15:40

school students work in the com industry in the

15:42

same week that I can live in this I

15:45

won't one are gonna get one of these. Sets.

15:47

Up A Dagger The Director of the Advanced

15:50

Structures and Composite Center at the University of

15:52

Maine. What's extra special about this home

15:54

he says is that it was. Three printed with

15:56

would fiber and bio. Weapon with all the

15:59

whole gullible. That are. Eventually Hopes to

16:01

be able to print one of these houses

16:03

in about Thirty eight and co printing to

16:05

someone took a lot longer. Once the pieces

16:07

are done, they can be ships and quickly

16:09

put together. To. Be screaming you get to

16:11

the house is her for the resembling the house or

16:13

a day and you don't. Be.

16:15

A Pdf goal of structures like these as. to

16:17

address a housing shortage going on in the

16:19

state. but that's not the only big thing

16:22

being made at the Composite. Center they

16:24

produced. A boat that actually floats.

16:26

Molds, For blades for offshore wind mills.

16:29

Even floor systems for high rise

16:31

buildings. Remember. How we talked

16:33

about large scale additive manufacturing. This is

16:35

where some of that is actually happening.

16:38

To printed stuff of course you need

16:40

a really big printer. The. One

16:42

at the University of Maine is the biggest

16:45

in the world. I got to see it

16:47

in action. actually. I stood inside it. To.

16:49

Give you a sense of just how big

16:51

it is. The printer is designed to print

16:53

objects as long as a hundred feet so

16:55

about to school buses and and and as

16:57

wide as twenty two feet which is a

16:59

little more than the with of to school

17:01

buses next to each other. It's a little

17:03

hard to hear Dagger here because we were

17:05

standing inside the printer. The

17:08

position for. Of. The

17:10

positions of food. Do

17:13

you work for those? The job as

17:15

a tool rather than under. The.

17:18

University of Maine Composite Center is

17:20

already using this treaty printer to

17:22

make things on behalf of clients

17:24

which include architecture firms and Us

17:26

governments. It inside of one

17:28

city. Has admitted

17:30

to go for a smoking

17:33

section of the city fitting

17:35

with the the way to

17:37

go by having most of

17:39

the section focuses about meeting

17:41

together. He. Is the key

17:43

to getting ready to the. Citizen.

17:45

Is what dagger cause The Factory of the

17:47

Future. Say. You have a factory that

17:50

makes parts for an airplane instead of having

17:52

one machine that does just one thing. The

17:54

vision for the factory of the future is

17:56

that each machine can do multiple things. That.

17:59

Only possible. With a lot of

18:01

feedback and communication between various instruments

18:03

working together. So. This is

18:05

a closed loop manufacturing process where

18:07

you pretty something you're sensing at

18:10

the same time the selling the

18:12

information the computer. And in

18:14

ai system comes back and say we're we're met

18:16

were going to fix this poses a problem and

18:18

it on it with over and a boyfriend for

18:20

more events. And muttered gap.

18:23

Status. As the university has raised

18:25

eighty one point five million dollars to

18:27

construct. The Statuary of the Future and will

18:29

be breaking ground later this year. And

18:32

he's as a lot is still don't know

18:34

yet like what kinds of materials that could

18:36

use and what industries it could make a

18:38

difference for. For. The first to

18:40

do with the sword scale and try

18:42

to really understand the opportunities as well

18:44

as the challenges to try to use

18:46

this technology and try to understand with

18:48

with the festival future cause not everything

18:50

can be friends with know that he

18:52

should be fitted at what can be

18:54

pretty much should be preserved and had

18:56

a presence of the challenges of classes.

18:59

For. Airbus hop assaults who we met earlier

19:01

suffer change like that could be a.

19:03

Big deal for it's manufacturing process

19:06

and it's Bottom Line: So

19:08

it could mean that to don't have

19:10

a big depots anymore was spare parts

19:12

for example. But you just produce on

19:15

demand, very flexible and it's a big

19:17

advantage of additive manufacturing twin resilient additive

19:19

manufacturing as an industrial resilient technology or

19:22

would say because it's very flexible. you

19:24

can use the same machine for lot

19:26

of different parts and so this is

19:29

a big big benefit. Those.

19:31

Shots as. A company has plans to

19:33

expand its use of treaty printing and the

19:35

future. it's still figuring out. When and how

19:38

to best use it. That's

19:40

especially true as the technology improves and

19:42

the people designing the machines. Figure

19:44

out how to do things like use new

19:46

materials and reduce waste. As.

19:48

Additive Manufacturing they she still are very

19:50

complicated technology and and expenses technology so

19:53

we would use it for something that

19:55

is very simple as he can know

19:57

do by sheet metal bending a simple

19:59

L brackets. You don't want

20:01

to princess that. A part that is

20:03

complex. it's integrates a lot of different

20:05

factions. Could. You see some

20:07

day a plan made entirely of.

20:09

Pretty printing, just the three different plane.

20:12

Since. Some they yes,

20:14

of course. I can imagine it's in

20:16

the near future and the next five

20:18

years, Ten years they're probably not. Airplanes

20:20

are still very complex and have a

20:23

lot of technologies to manufacture them. The

20:27

Future of Everything as a production of

20:29

the Wall Street Journal, Seventy Elgon frets

20:31

in the Editorial Director of the Future

20:33

of Everything. This episode was produced by

20:36

me. Alex Avila and me Danny Louis

20:38

are fact checker as a partner Nathan

20:40

Michael a vow and just a function

20:42

or are sound designers and wrote our

20:44

theme music. Cotton Mill Sauce is our

20:47

supervising producer. As clean

20:49

as our development producer. Not

20:51

fall Away and Chris Simpli or the deputy

20:53

editor and for lot of Harrison is ahead

20:56

of new audio for the Wall Street Journal

20:58

with the show Styrofoam and leave us a

21:00

five star review on a silver platter. And

21:03

for listening.

From The Podcast

WSJ’s The Future of Everything

What will the future look like? The Future of Everything offers a view of the nascent trends that will shape our world. In every episode, join our award-winning team on a new journey of discovery. We’ll take you beyond what’s already out there, and make you smarter about the scientific and technological breakthroughs on the horizon that could transform our lives for the better.Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

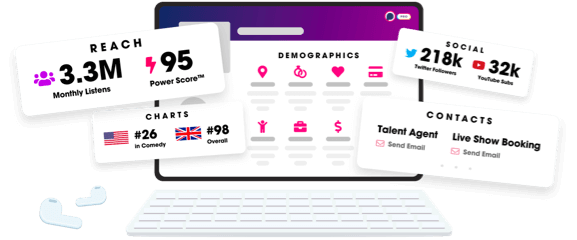

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us